A kind of preparation method of tetramercaptosilsesquioxane modified waterborne polyurethane color fixing agent

A technology of silsesquioxane and water-based polyurethane, which is applied in dyeing, textiles and papermaking, etc., can solve the problems affecting the stability of emulsion, thermal stability, etc., to improve the color fastness to rubbing, long-term use, good The effect of suspension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

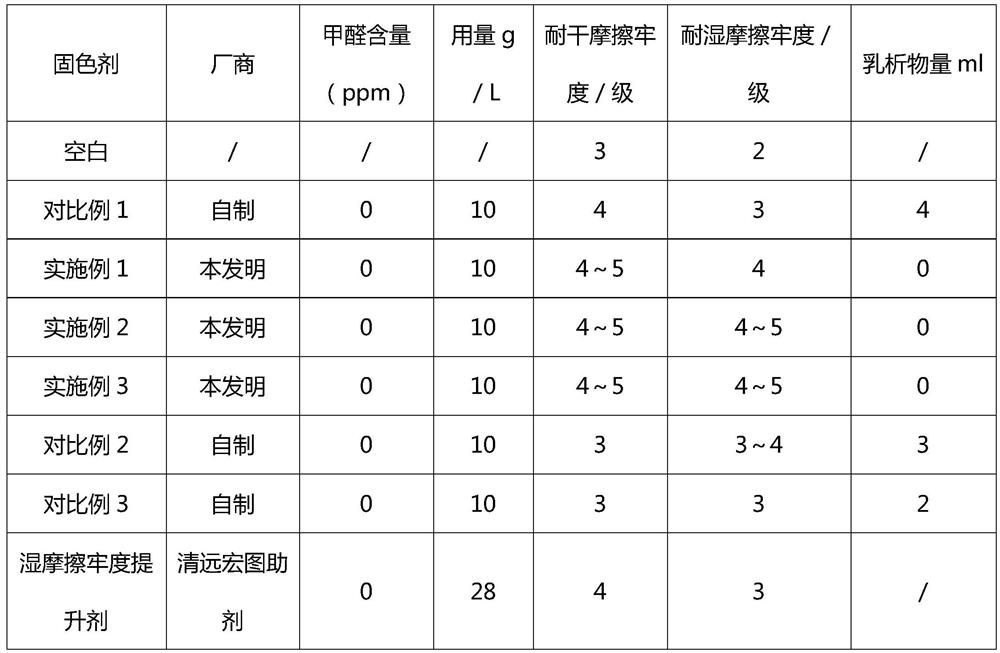

Examples

Embodiment 1

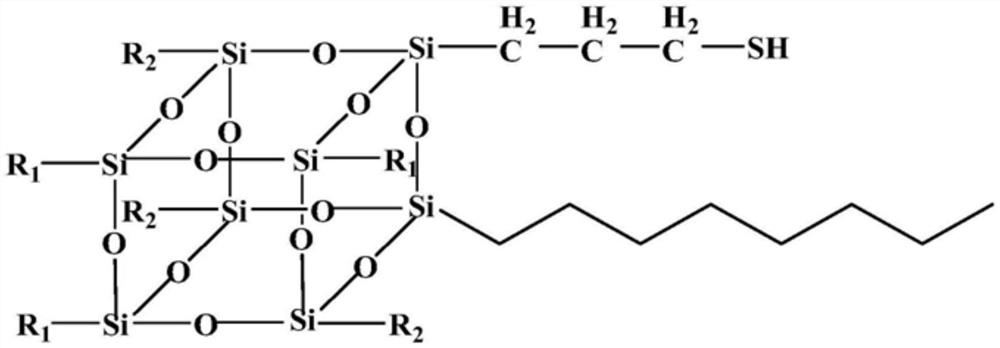

[0025] Synthesis of tetramercaptosilsesquioxane modified waterborne polyurethane (tetramercaptosilsesquioxane accounts for 0.5% of the total mass of polyol, diisocyanate and chain extender)

[0026] (1) Preparation of tetramercaptosilsesquioxane: 19.6g of 3-mercaptopropyltrimethoxysilane (Guangzhou Shuangtao Fine Chemical Co., Ltd.) and 27.64g of octyltriethoxysilane (Suzhou Siloso New Material Co., Ltd. company) into a flask equipped with magnetic stirring and a condenser, while adding 100ml of concentrated hydrochloric acid and 1200ml of methanol. The mixture was reacted at 90°C for 36 hours under stirring, then cooled to remove methanol solvent, the crude product was washed with cold methanol several times to remove excess oligomeric silsesquioxane, and dried in vacuum to obtain viscous liquid tetramercapto silsesquioxane alkyl.

[0027] (2) Synthesis of tetramercaptosilsesquioxane-modified water-based polyurethane: add 100g polyethylene glycol 1000, 31.32g toluene diisocy...

Embodiment 2

[0029] Synthesis of tetramercaptosilsesquioxane modified waterborne polyurethane (tetramercaptosilsesquioxane accounts for 0.8% of the total mass of polyol, diisocyanate and chain extender)

[0030] (1) Preparation of tetramercaptosilsesquioxane: Add 19.6g of 3-mercaptopropyltrimethoxysilane and 27.64g of octyltriethoxysilane into a flask equipped with a magnetic stirrer and a condenser, and simultaneously add 100ml concentrated hydrochloric acid and 1200ml methanol. The mixture was reacted at 90°C for 36 hours under stirring, then cooled to remove methanol solvent, the crude product was washed with cold methanol several times to remove excess oligomeric silsesquioxane, and dried in vacuum to obtain viscous liquid tetramercapto silsesquioxane alkyl.

[0031] (2) Synthesis of tetramercaptosilsesquioxane-modified water-based polyurethane: add 100g polyethylene glycol 1000, 31.32g toluene diisocyanate, 52.5g 1-methyl-2-pyrrolidone to a four-necked flask, at 70°C React at low te...

Embodiment 3

[0033] Synthesis of tetramercaptosilsesquioxane modified waterborne polyurethane (tetramercaptosilsesquioxane accounts for 1% of the total mass of polyol, diisocyanate and chain extender)

[0034](1) Preparation of tetramercaptosilsesquioxane: Add 19.6g of 3-mercaptopropyltrimethoxysilane and 27.64g of octyltriethoxysilane into a flask equipped with a magnetic stirrer and a condenser, and simultaneously add 100ml concentrated hydrochloric acid and 1200ml methanol. The mixture was reacted at 90°C for 36 hours under stirring, then cooled to remove methanol solvent, the crude product was washed with cold methanol several times to remove excess oligomeric silsesquioxane, and dried in vacuum to obtain viscous liquid tetramercapto silsesquioxane alkyl.

[0035] (2) Synthesis of tetramercaptosilsesquioxane-modified water-based polyurethane: add 100g polyethylene glycol 1000, 31.32g toluene diisocyanate, 52.5g 1-methyl-2-pyrrolidone to a four-necked flask, at 70°C React at low tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com