A method for preparing a boronizing layer on the surface of a high-entropy alloy

A technology of high-entropy alloy and boronizing layer, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as easy to fall off, difficult to exert the performance of high-entropy alloy, and weak matrix bonding force , to achieve the effects of high bonding strength, fast permeation speed, and process deformation and gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

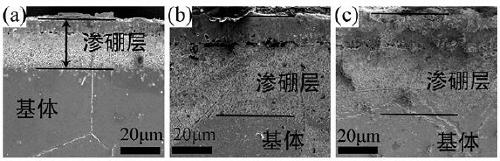

[0026] A high entropy alloy Al 0.25 The preparation method of CoCrFeNi surface boronizing layer, concrete steps are as follows:

[0027] (1) Processing Al 0.25 CoCrFeNi sample:

[0028] When processing high-entropy alloy substrate samples, a cutting machine was used to process samples with a size of 10 mm × 10 mm × 1.5 mm.

[0029] (2) Clean Al 0.2 5CoCrFeNi sample surface:

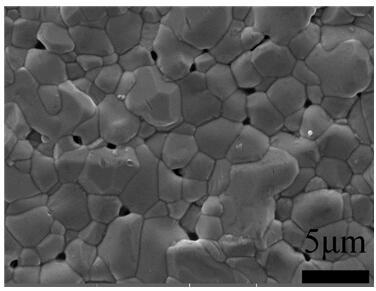

[0030] When cleaning the surface of the high-entropy alloy substrate sample, grind the alloy sample with 300#, 800#, 1000#, 1500# and 2500# SiC sandpaper of different particle sizes in sequence, and then use diamond polishing paste with a particle size of 0.5 μm for mechanical polishing There are no scratches on the surface under a 100x optical microscope, and finally cleaned with an ultrasonic cleaner in alcohol for 5 minutes, and dried for later use.

[0031] (3) Put the cleaned high-entropy alloy sample in a stainless steel container filled with powder boronizing agent, seal it with water glass an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com