Method for preparing bismuth telluride thermoelectric thin film with heterostructure

A technology of thermoelectric thin film and heterogeneous structure, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of single structure of thermoelectric thin film material and low thermoelectric performance, and achieve the advantages of transportation, thermal Reduced conductivity and reduced scattering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing a bismuth telluride thermoelectric thin film with a heterostructure, which specifically includes the following steps:

[0047] (1) Before preparing the bismuth telluride thermoelectric thin film, the equipment cavity should be cleaned first, and the corresponding target head and shield cover should be wiped with alcohol and acetone;

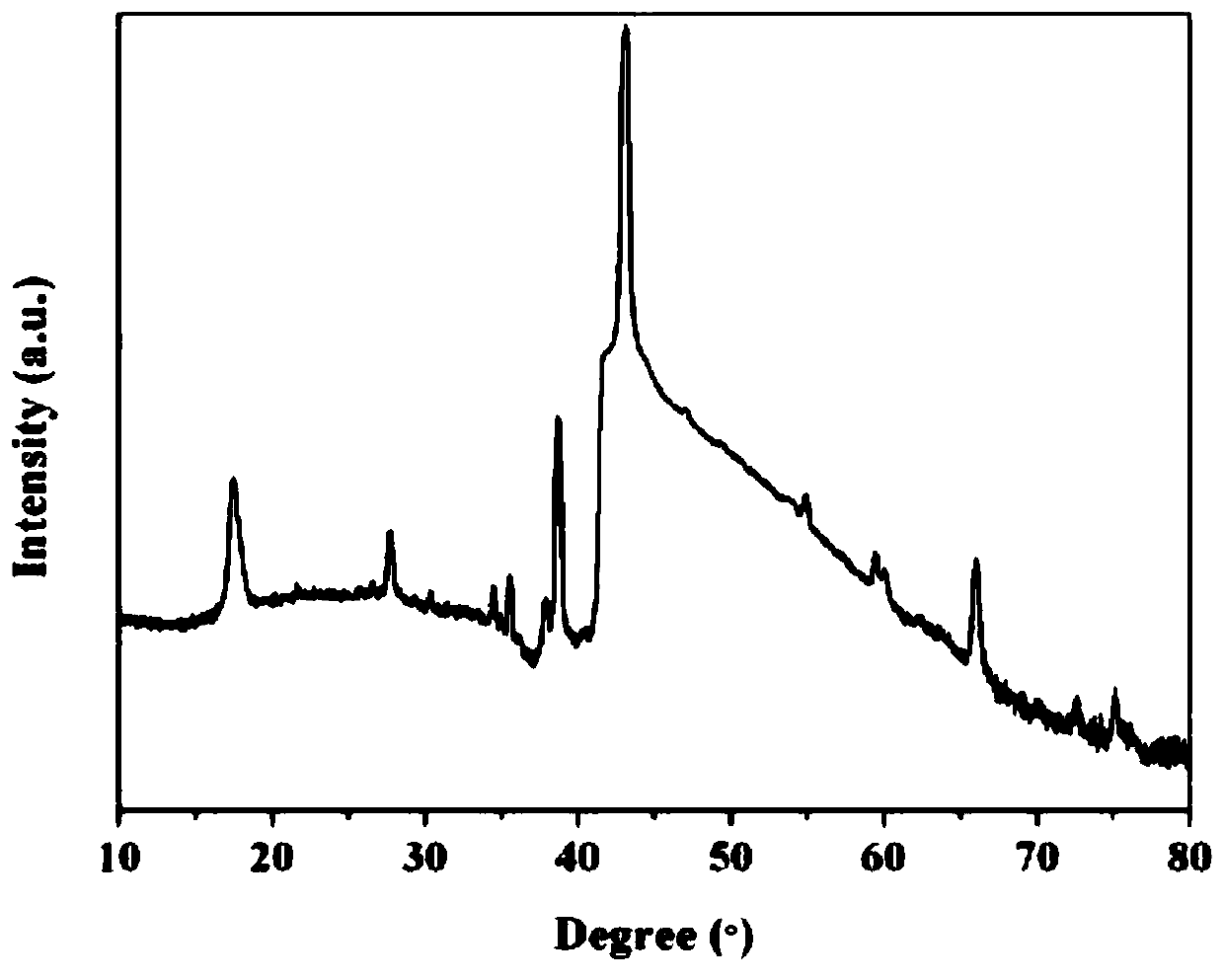

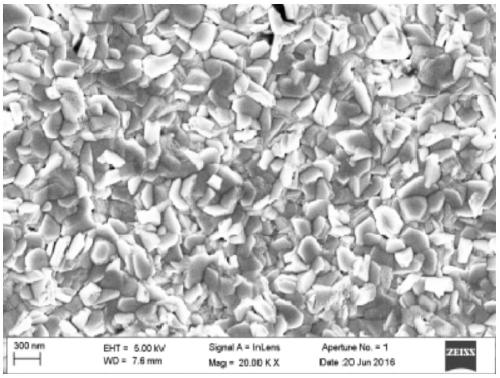

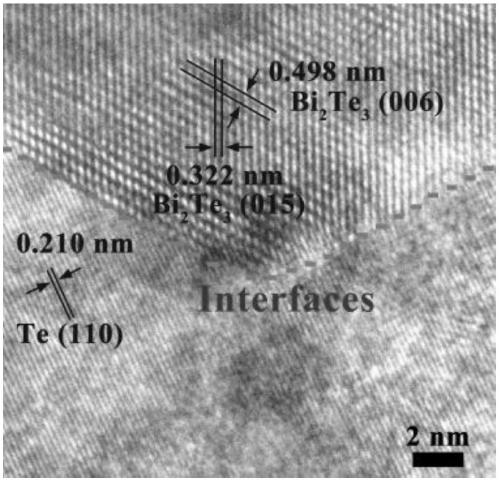

[0048] (2) Mix metal powder Bi and Te with a purity of 99.999% according to the molar ratio of Bi:Te=2:3, and use a hot isostatic pressing device under the condition of 200MPa to make a high-density bismuth telluride alloy target, And install the bismuth telluride alloy target on the target head connected to the DC source in the cavity of the magnetron sputtering equipment; the metal powder Te with a purity of 99.999% is made into a simple tellurium by using a hot isostatic pressing device under the condition of 150MPa target, and install the tellurium simple substance target on the target he...

Embodiment 2

[0059] This embodiment provides a method for preparing a bismuth telluride thermoelectric thin film with a heterostructure, which specifically includes the following steps:

[0060] (1) Before preparing the bismuth telluride thermoelectric thin film, the equipment cavity should be cleaned first, and the corresponding target head and shield cover should be wiped with alcohol and acetone;

[0061] (2) Mix metal powder Bi and Te with a purity of 99.999% according to the molar ratio of Bi:Te=2:3, and use a hot isostatic pressing device under the condition of 200MPa to make a high-density bismuth telluride alloy target, And install the bismuth telluride alloy target on the target head connected to the DC source in the cavity of the magnetron sputtering equipment; the metal powder Te with a purity of 99.999% is made into a simple tellurium by using a hot isostatic pressing device under the condition of 150MPa target, and install the tellurium simple substance target on the target he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com