Preparation method for copper base material photovoltaic welding strip

A technology of photovoltaic ribbon and copper substrate, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as uneven surface thickness, uneven welding, low refractive index, etc., to reduce optical power Loss, enhanced adhesion, surface smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

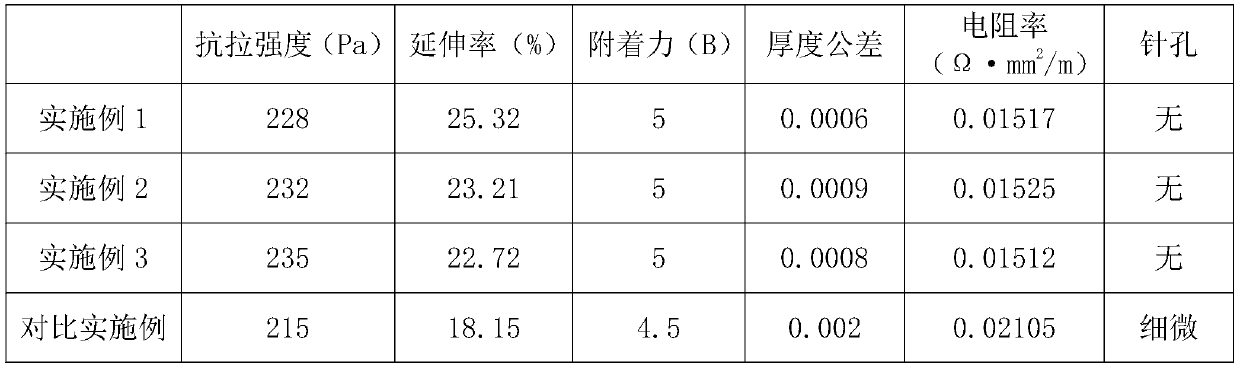

Examples

Embodiment 1

[0024] A method for preparing a copper-based photovoltaic ribbon, characterized in that it specifically comprises the following steps:

[0025] 1) Cleaning the copper substrate with an acidic solution to remove dirt and impurities on the surface of the copper substrate;

[0026] 2) performing plasma treatment on the surface of the copper substrate;

[0027] 3) Vacuum depositing a base alloy layer on the surface of the copper substrate;

[0028] 4) A layer of solder is brush-plated on the surface of the primer alloy layer by using an electric brush plating process to obtain a finished copper-based photovoltaic ribbon.

[0029] The step 1) acidic solution is composed of the following raw materials in weight percentage: 15% hydrochloric acid, 10% hydrogen peroxide, 6% benzimidazole, and the rest is water, and the acidic solution treatment time is 80s.

[0030] The step 2) plasma treatment adopts normal temperature and pressure plasma treatment, the power of plasma treatment is ...

Embodiment 2

[0037] A method for preparing a copper-based photovoltaic ribbon, characterized in that it specifically comprises the following steps:

[0038] 1) Cleaning the copper substrate with an acidic solution to remove dirt and impurities on the surface of the copper substrate;

[0039] 2) performing plasma treatment on the surface of the copper substrate;

[0040] 3) Vacuum depositing a base alloy layer on the surface of the copper substrate;

[0041] 4) A layer of solder is brush-plated on the surface of the primer alloy layer by using an electric brush plating process to obtain a finished copper-based photovoltaic ribbon.

[0042] The step 1) acid solution is composed of the following raw materials in weight percentage: 10% hydrochloric acid, 5% hydrogen peroxide, 2% benzimidazole, and the rest is water, and the treatment time of the acid solution is 40s.

[0043] The step 2) plasma treatment adopts normal temperature and pressure plasma treatment, the power of plasma treatment i...

Embodiment 3

[0050] A method for preparing a copper-based photovoltaic ribbon, characterized in that it specifically comprises the following steps:

[0051] 1) Cleaning the copper substrate with an acidic solution to remove dirt and impurities on the surface of the copper substrate;

[0052] 2) performing plasma treatment on the surface of the copper substrate;

[0053] 3) Vacuum depositing a base alloy layer on the surface of the copper substrate;

[0054] 4) A layer of solder is brush-plated on the surface of the primer alloy layer by using an electric brush plating process to obtain a finished copper-based photovoltaic ribbon.

[0055] The step 1) acid solution is composed of the following raw materials in weight percentage: 28% hydrochloric acid, 15% hydrogen peroxide, 8% benzimidazole, and the rest is water, and the treatment time of the acid solution is 150s.

[0056] The step 2) plasma treatment adopts normal temperature and pressure plasma treatment, the power of plasma treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com