Modified separator, preparation method thereof and lithium ion battery

A diaphragm and modification technology, applied in the field of modified diaphragm and its preparation method and lithium ion battery, can solve the problems of producing lithium dendrite, low migration number, battery concentration polarization, etc., to reduce the AC impedance value, improve the Safety performance, the effect of extending the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a method for preparing the above-mentioned modified diaphragm, which includes the following steps: coating a polymer whose side chain is substituted with lithium sulfonate on at least one surface of the diaphragm substrate. Preferably, before the coating step, the preparation method of the above-mentioned modified diaphragm further includes the following steps: dissolving in an organic solvent to prepare a solution with a polymer percentage of 3wt.% to 10wt.%. The vinylidene fluoride-hexafluoropropylene copolymer is dissolved in an organic solvent to prepare a polyvinylidene fluoride-hexafluoropropylene copolymer solution with a percentage content of 0wt.% to 50wt.%, and the two solutions are mixed uniformly to obtain a mixed solution. The mixed solution is coated on at least one surface of the separator substrate. Preferably, the polyvinylidene fluoride-hexafluoropropylene copolymer has a number average molecular we...

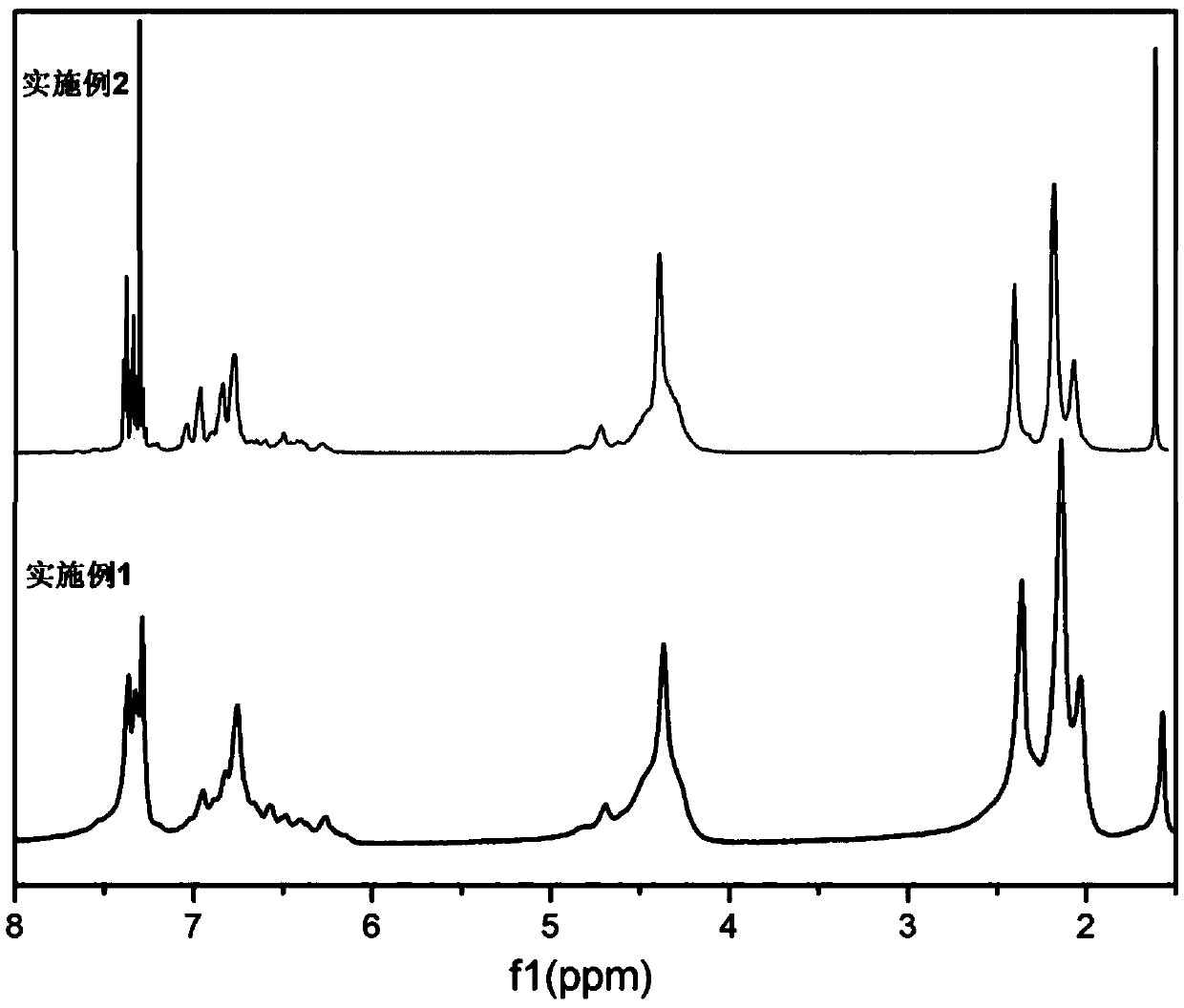

Embodiment 1

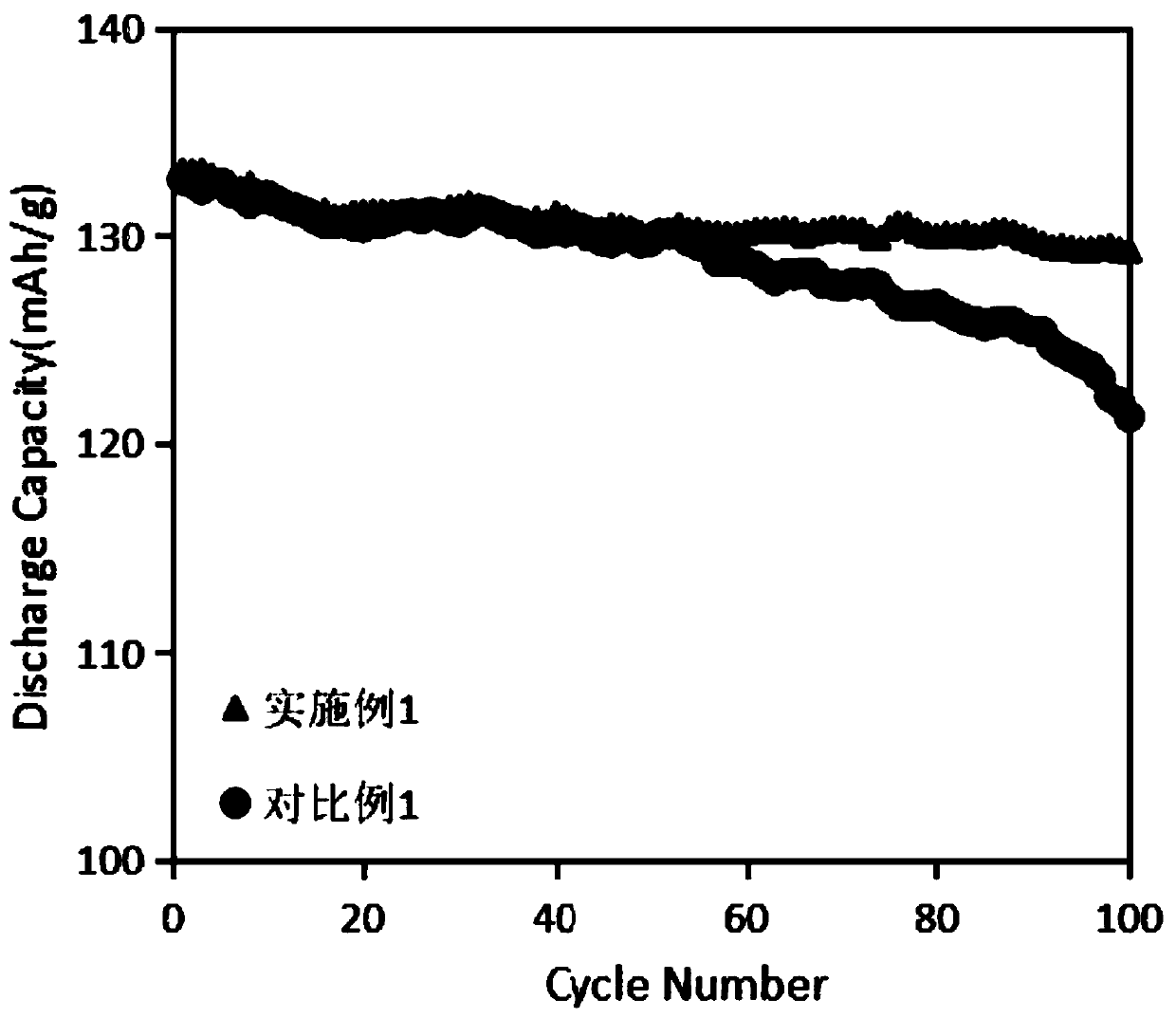

[0049] This embodiment provides a modified diaphragm, which includes a polyethylene diaphragm substrate and a polyphenylene ether coating whose side chains are substituted by sulfonate lithium on both surfaces of the polyethylene diaphragm; wherein, the porosity of the polyethylene diaphragm is 40%, and the thickness is 9 μm; the polyphenylene ether substitution degree of the side chain in the polyphenylene ether coating is 66%, and its mass percentage in the coating is 70%. The thickness of the coating on the surface was 3 μm. Three sets of parallel tests of the above-mentioned modified separator showed that the average lithium ion migration number was 0.44, and the average conductivity was 0.12 mS / cm.

[0050] The preparation method of the modified membrane of the present embodiment comprises the following steps:

[0051] (1) Weigh polyphenylene ether and dissolve it in N-methylpyrrolidone, raise the temperature to 100°C immediately after introducing nitrogen gas, and add l...

Embodiment 2

[0059]This embodiment provides a modified diaphragm, which includes a polypropylene diaphragm substrate and a polyarylether ketone coating whose side chains are substituted by lithium sulfonate on both surfaces of the polypropylene diaphragm; wherein, the pores of the polypropylene diaphragm The ratio is 40%, and the thickness is 9 μm; the substitution degree of polyaryletherketone in the polyaryletherketone coating is 72%, and its mass percentage in the coating is 70%. The thickness of the coating on each surface is 3 μm. Three sets of parallel tests of the above-mentioned modified separator showed that the average lithium ion migration number was 0.55, and the average conductivity was 0.19 mS / cm.

[0060] The preparation method of the modified membrane of the present embodiment comprises the following steps:

[0061] (1) Weigh polyaryletherketone and dissolve it in N-methylpyrrolidone, raise the temperature to 140°C immediately after feeding nitrogen, and drop liquid bromin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com