Alfacalcidol soft capsule and preparation method thereof

A technology of alfacalcidol and soft capsules, which is applied in capsule delivery, bone diseases, pharmaceutical formulations, etc., and can solve the problems of poor stability, unsatisfactory stability, and low bioavailability of alfacalcidol, and achieve improved Drug stability, improve bioavailability, improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

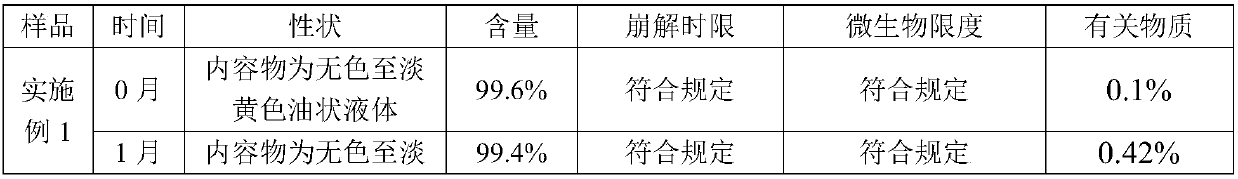

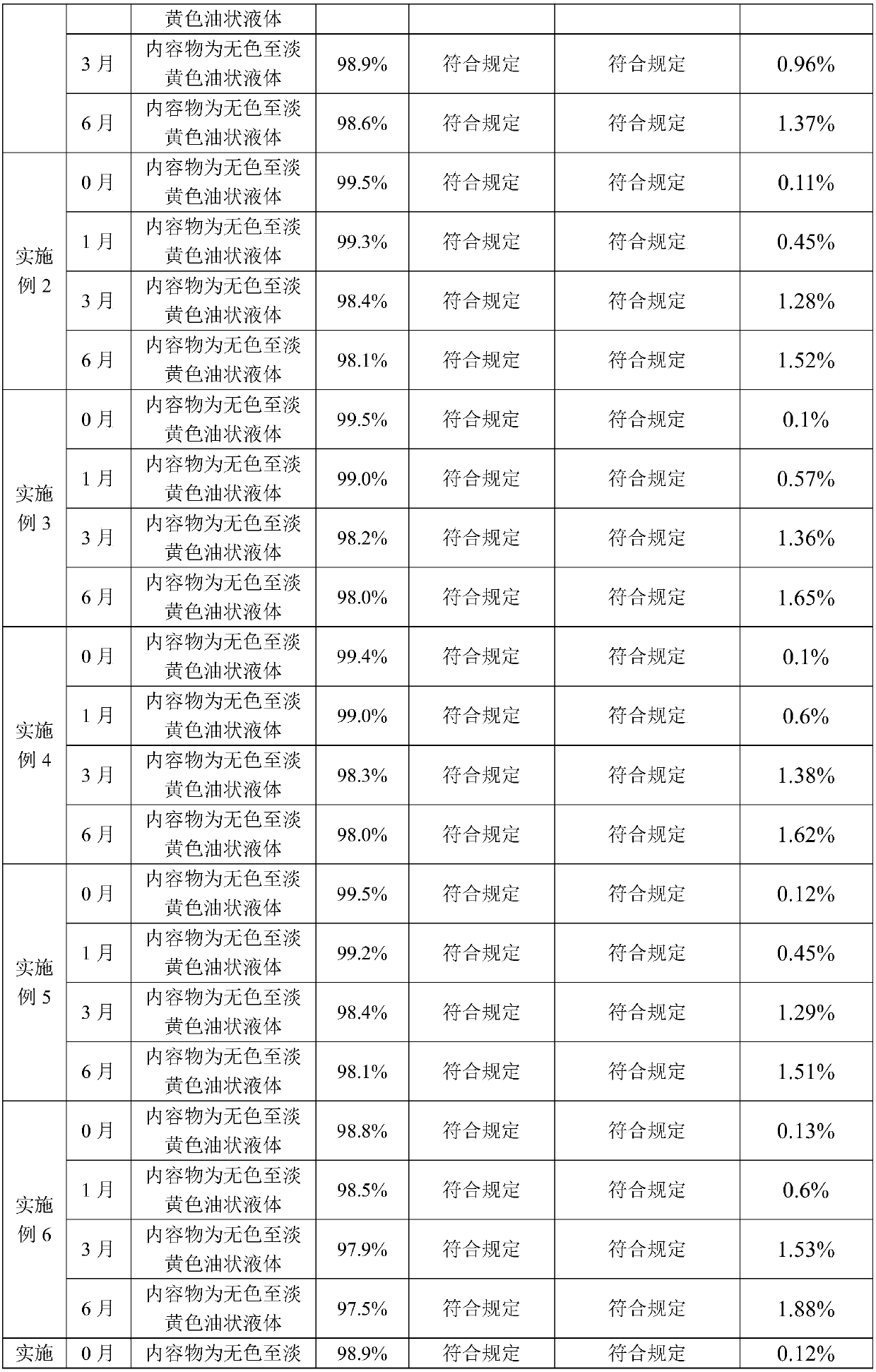

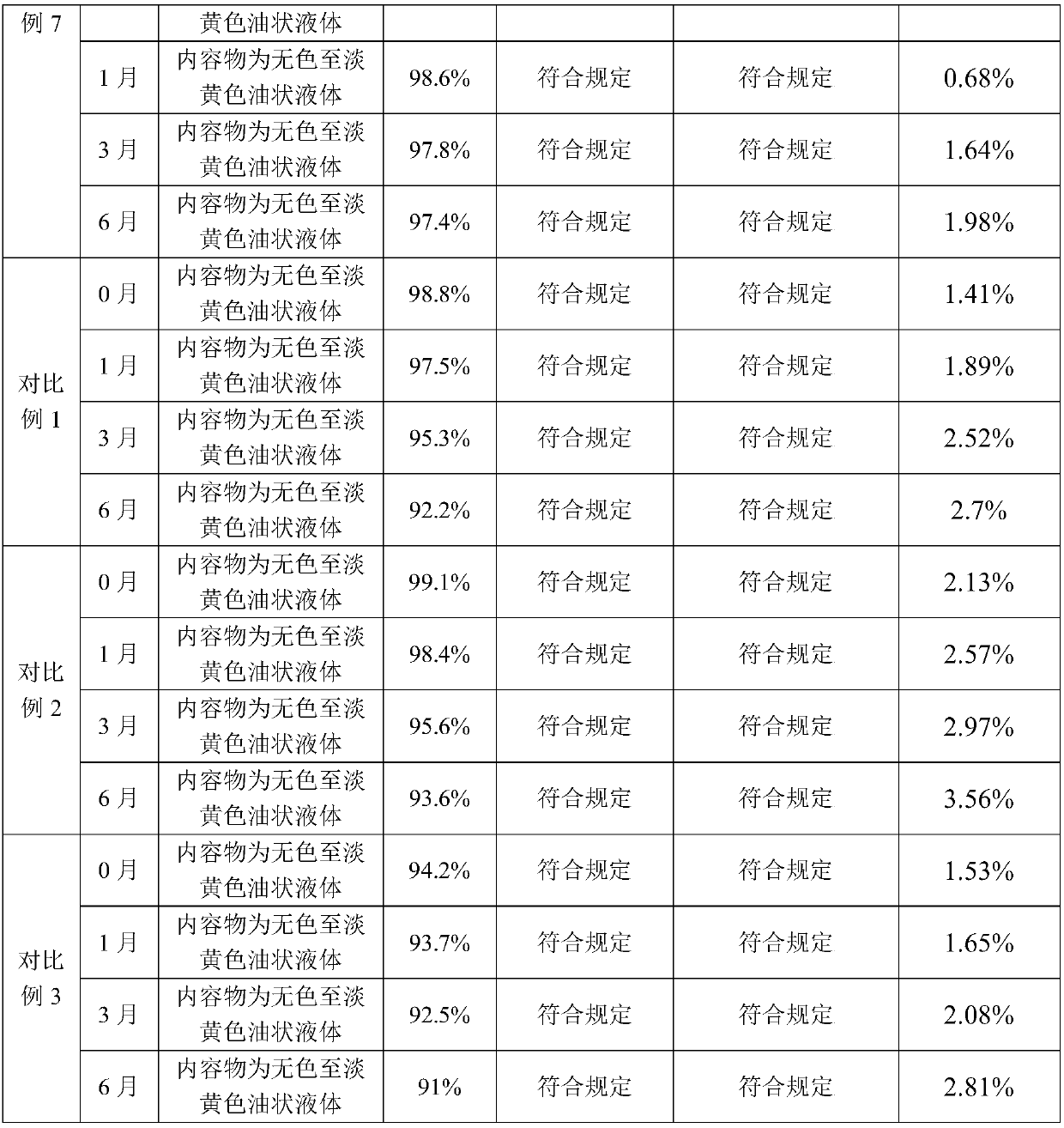

Examples

Embodiment 1

[0048] The present embodiment provides a kind of alfacalcidol soft capsule, and its content is made up of following components:

[0049] Medium chain triglycerides 105 parts

[0050] Ascorbyl palmitate 0.08 parts

[0051] Alfacalcidol 0.0000025 parts

[0052] The preparation method is as follows:

[0053] 1. Get the antioxidant (ascorbyl palmitate) and 8% oily base (medium-chain triglyceride) and fully mix to obtain a mixture.

[0054] 2. Pour the remaining amount of oily base into the liquid mixing tank, and add the mixture obtained in 1 into the liquid mixing tank, then stir for 20 minutes (rotation speed is 120r / min), and mix well.

[0055] 3. Protect from light, add alfacalcidol in the liquid mixing tank, and stir (120r / min) under the protection of nitrogen (the pressure after nitrogen filling) for 1 hour to obtain the content.

[0056] 4. Protect from light, put the content into the liquid storage tank, use a fully automatic soft capsule machine to prepare soft capsul...

Embodiment 2

[0058] The present embodiment provides a kind of alfacalcidol soft capsule, and its content is made up of following components:

[0059] Medium chain triglycerides 105 parts

[0060] Ascorbyl palmitate 0.16 parts

[0061]Alfacalcidol 0.0000025 parts

[0062] The preparation method is as follows:

[0063] 1. Get the antioxidant (ascorbyl palmitate) and 8% oily base (medium-chain triglyceride) and fully mix to obtain a mixture.

[0064] 2. Pour the remaining amount of oily base into the liquid mixing tank, and add the mixture obtained in 1 into the liquid mixing tank, then stir for 20 minutes (rotation speed is 120r / min), and mix well.

[0065] 3. Protect from light, add alfacalcidol in the liquid mixing tank, and stir (120r / min) under the protection of nitrogen (the pressure after nitrogen filling) for 1 hour to obtain the content.

[0066] 4. Protect from light, put the content into the liquid storage tank, use a fully automatic soft capsule machine to prepare soft capsule...

Embodiment 3

[0068] The present embodiment provides a kind of alfacalcidol soft capsule, and its content is made up of following components:

[0069] Medium chain triglycerides 105 parts

[0070] Ascorbyl palmitate 0.04 parts

[0071] Alfacalcidol 0.0000025 parts

[0072] The preparation method is as follows:

[0073] 1. Get the antioxidant (ascorbyl palmitate) and 8% oily base (medium-chain triglyceride) and fully mix to obtain a mixture.

[0074] 2. Pour the remaining amount of oily base into the liquid mixing tank, and add the mixture obtained in 1 into the liquid mixing tank, then stir for 20 minutes (rotation speed is 120r / min), and mix well.

[0075] 3. Protect from light, add alfacalcidol in the liquid mixing tank, and stir (120r / min) under the protection of nitrogen (the pressure after nitrogen filling) for 1 hour to obtain the content.

[0076] 4. Protect from light, put the content into the liquid storage tank, use a fully automatic soft capsule machine to prepare soft capsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com