A kind of purification method of trimethylaluminum crude product

A technology of trimethylaluminum crude product and purification method, which is applied in the field of purification of trimethylaluminum crude product, can solve the problems of high cost and large liquid holding capacity, and achieve simple manufacturing process, improved heat transfer capacity and good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for purifying trimethylaluminum crude product, comprising the following steps:

[0026] (1) The microchannel rectification tower is exchanged with inert gas, and the crude product of trimethylaluminum (purity 99.93%) is transferred to the rectification kettle;

[0027] (2) After the materials are transferred, close the feed valve and carry out rectification. Rectification pressure: 0.02MPa, rectification temperature: 80°C.

[0028] (3) intercept the distilled material with a boiling point of 125-127°C under standard atmospheric pressure, and collect it with a cold trap to obtain a high-purity trimethylaluminum product. Detected by ICP-MS and NMR, the purity of trimethylaluminum obtained by the method of this embodiment is calculated to be 7.0N (99.99999%).

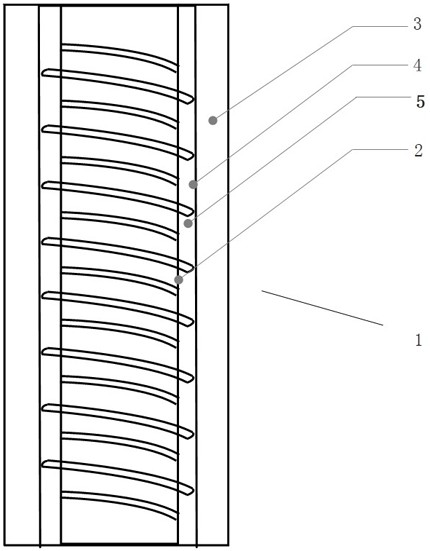

[0029] The structure of the microchannel rectification tower is: the distillation column inside the rectification tower is two concentric column structures (inner tube 2 and outer tube 3), and the material...

Embodiment 2

[0031] A method for purifying trimethylaluminum crude product, is characterized in that, comprises the following steps:

[0032] (1) The microchannel rectification tower is exchanged with inert gas, so that the atmosphere of ultra-low water and oxygen content is maintained in the tower, and the crude product of trimethylaluminum (purity 99.93%) is transferred to the rectification kettle with a slight vacuum;

[0033] (2) After the materials are transferred, close the feed valve and carry out rectification. Rectification pressure: 0.05MPa Rectification temperature: 100°C.

[0034] (3) intercept the distilled material with a boiling point of 125-127°C under standard atmospheric pressure, and collect it with a cold trap to obtain a high-purity trimethylaluminum product. Detected by ICP-MS and NMR, it is calculated that the purity of trimethylaluminum obtained by the method of this embodiment is 7.3N (99.999993%).

[0035] The structure of the microchannel rectification tower is ...

Embodiment 3

[0037] A method for purifying trimethylaluminum crude product, comprising the following steps:

[0038] (1) The microchannel rectification tower is exchanged with inert gas, so that the atmosphere of ultra-low water and oxygen content is maintained in the tower, and the crude product of trimethylaluminum (purity 99.93%) is transferred to the rectification kettle with a slight vacuum;

[0039] (2) After the materials are transferred, close the feed valve and carry out rectification. Rectification temperature: 128°C, rectification pressure: 0.1MPa.

[0040] (3) intercept the distilled material with a boiling point of 125-127°C under standard atmospheric pressure, and collect it with a cold trap to obtain a high-purity trimethylaluminum product. Detected by ICP-MS and NMR, the purity of trimethylaluminum obtained by the method of this embodiment is calculated to be 7.2N (99.999992%).

[0041] The structure of the microchannel rectification tower is as follows: the distillation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com