Environment-friendly processing method and system of agricultural class-A sludge biochar fertilizer and environment-friendly rotary sludge dryer used in method and system

A processing method and technology of biochar, applied in the direction of water/sludge/sewage treatment, sludge treatment, fertilizer mixture, etc., can solve the problems of being unable to be absorbed and utilized by plants, losing biological properties, etc., to increase revenue and profit, improve Value and price, effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

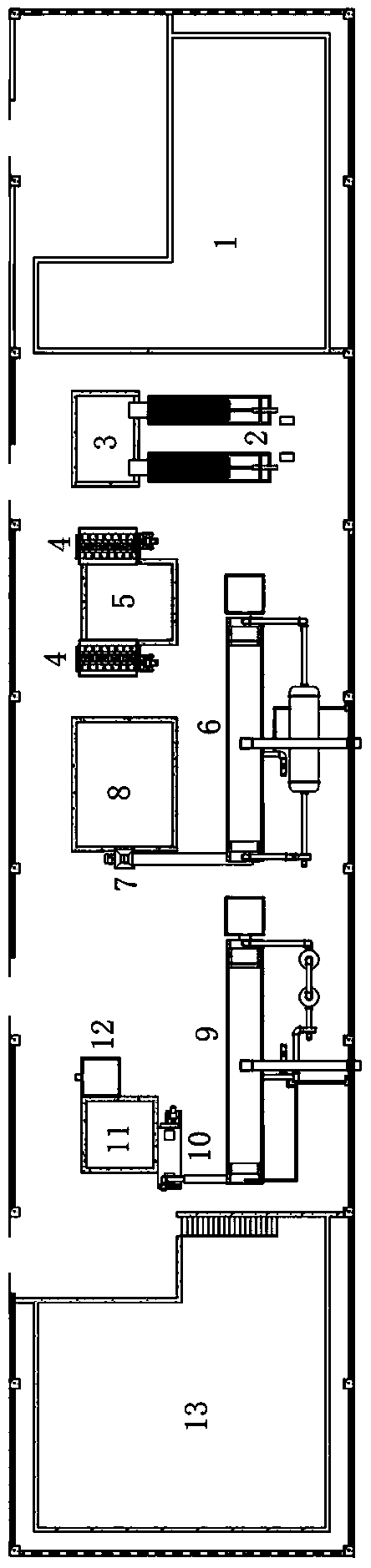

[0060] see figure 1 , the environmental protection type processing method of agricultural grade A sludge biochar fertilizer of the present invention, comprises the steps:

[0061] 1) Firstly, the thin sludge with a water content of 98-99% produced by the domestic sewage treatment plant is added to the concentrated chemical for precipitation and concentration, and the concentrated sludge with a water content of 95-96% is obtained;

[0062] 2) High-pressure dehydration of concentrated sludge with a moisture content of 95-96% to obtain dewatered sludge with a moisture content of 48-52%;

[0063] 3) Add a certain amount of humic acid to the dewatered sludge with a moisture content of 48-52%, and use a biaxial forced sludge mixer to mix and dry it to obtain a semi-dried mixed sludge with a moisture content of 23-38%;

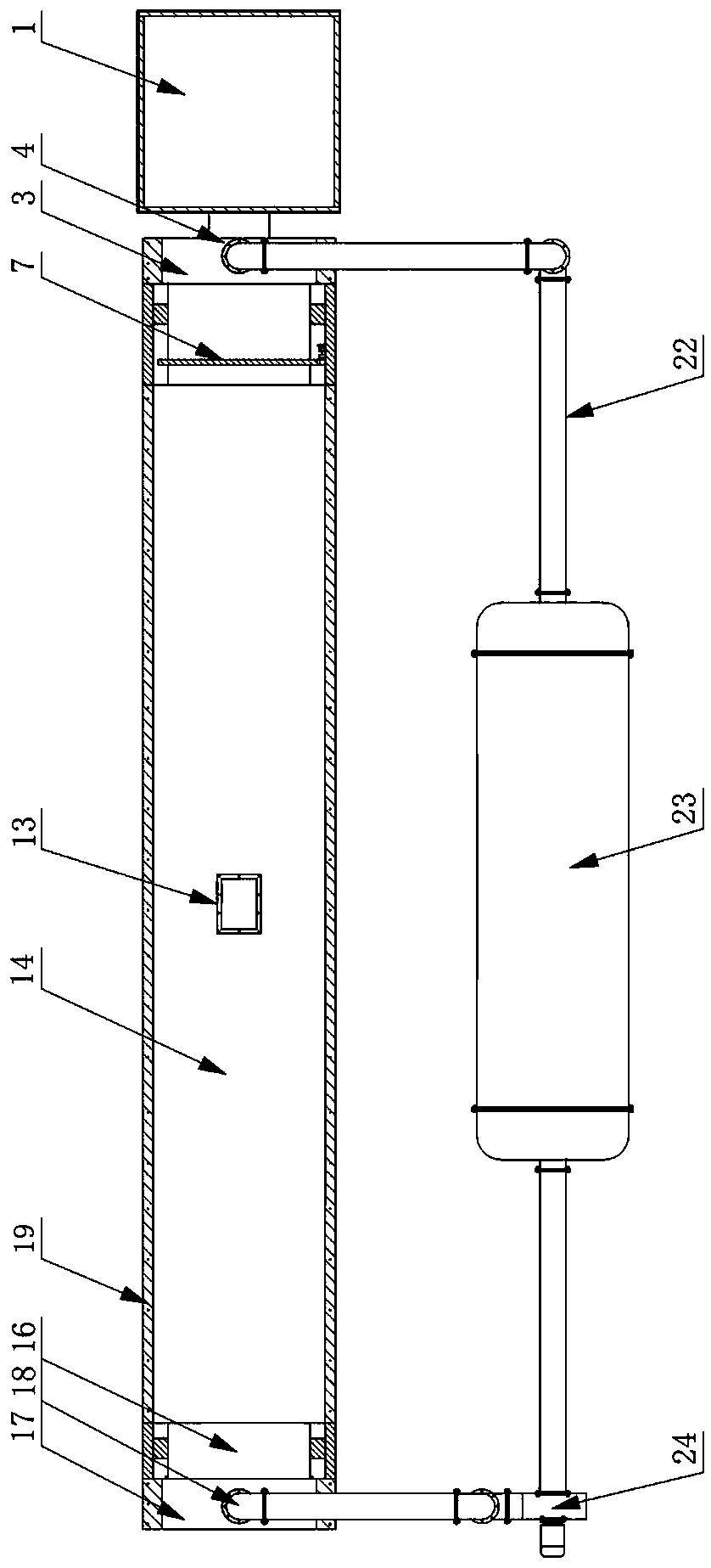

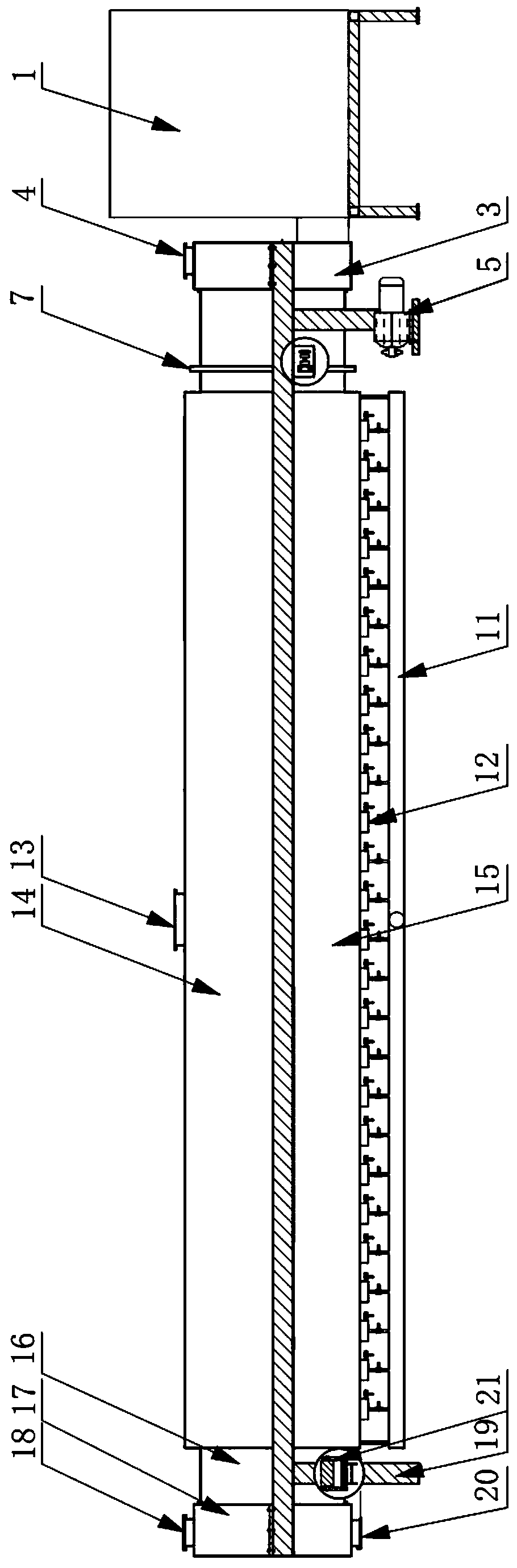

[0064] 4) Use an environment-friendly rotary sludge dryer to heat and dry the semi-dried mixed sludge with a moisture content of 23-38%:

[0065](1) The heating fu...

Embodiment 2

[0083] see figure 1 , the environment-friendly processing method of the agricultural grade A sludge biochar fertilizer of the present embodiment is different from the embodiment 1 in that: the thin sludge is pumped into the sludge concentration tank, and the concentrated medicament dosing machine is provided on the delivery pipeline 1. Quantitatively add aluminum ferric chloride concentration agent with a concentration of 5-10% through the metering pump and mix it. After mixing, it flows into the concentration tank for precipitation and concentration. The supernatant flows out from the outlet above the concentration tank into the sewer, and the sludge becomes concentrated sludge after concentration; 1 Add 5-10 kg aluminum ferric chloride concentrated agent to 1 ton of dewatered sludge.

[0084] The effect of using ferric aluminum chloride concentrated agent is better, and ferric aluminum chloride has a large specificity, which makes the sludge easy to precipitate quickly; othe...

Embodiment 3

[0086] see figure 1 , the environment-friendly processing method of agricultural grade A sludge biochar fertilizer of this embodiment is different from Embodiment 1 or Embodiment 2 in that: further, the concentrated sludge is dehydrated under high pressure by a sludge high-pressure dehydrator, concentrated The sludge is pumped from the bottom of the thickening tank into the sludge high-pressure dehydrator through the pipeline through the sludge pump, the feed pressure is 16-20 kg / cm2, the secondary pressing pressure is 65-110 kg / cm2, and the moisture content of the sludge after high-pressure dehydration It is very low, so that the microorganisms lose the environment for a large number of reproduction, so as to avoid the odor generated by the fermentation of dewatered sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com