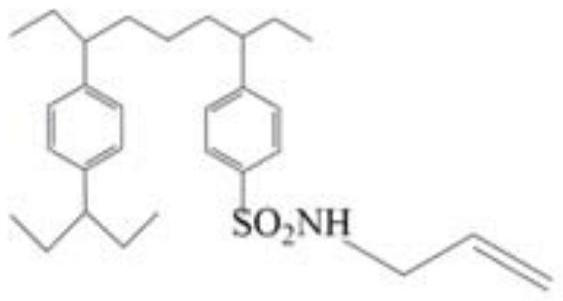

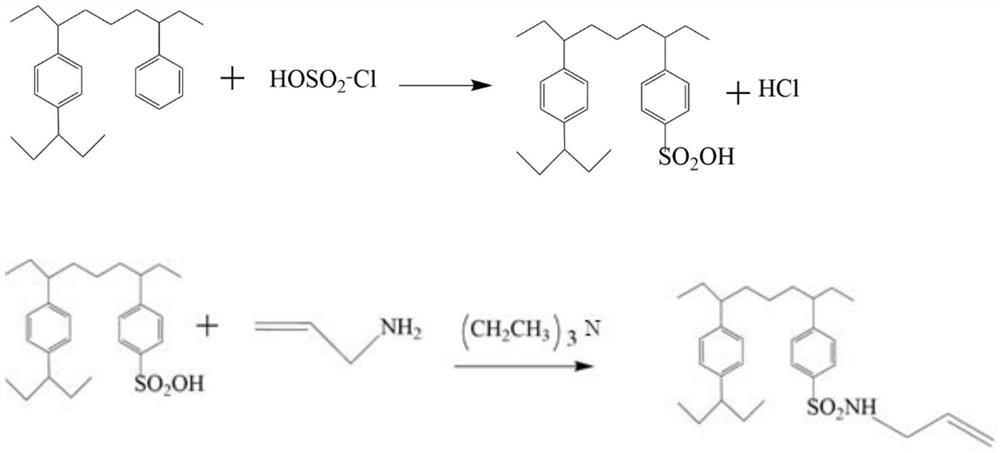

A kind of sulfonamide allyl polystyrene cross-linked microsphere and preparation method thereof

A technology of allyl polystyrene and sulfonyl chloride polystyrene, which is applied in the fields of sulfonamide allyl polystyrene cross-linked microspheres allylamine and its preparation, and modified polystyrene cross-linked microspheres, It can solve the problem that allylamine functional microspheres are not reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of sulfonamide allyl polystyrene cross-linked microspheres, its preparation steps are as follows:

[0027] a), preparation of sulfonyl chloride polystyrene cross-linked microspheres: in parts by weight, add 3 parts of polystyrene cross-linked microspheres with 4.5% cross-linking degree and two 40 parts of methyl chloride, stir to fully swell the microspheres, slowly add 90 parts of chlorosulfonic acid at a controlled temperature of 20°C, raise the temperature to 50°C and keep it warm for 3 hours, after the reaction, cool down to 30°C and let it stand for 8 hours; then at 20°C Add 15mL of distilled water to decompose excess chlorosulfonic acid until there is no large amount of HCl gas released in the solution; add 90mL of distilled water within 1h under stirring to make the product precipitate as much as possible, filter with suction, and use 1,4-diox Washing with six rings to remove the residual solvent, then alternately washing with distilled water and ethanol f...

Embodiment 2

[0030] A kind of sulfonamide allyl polystyrene cross-linked microspheres, its preparation steps are as follows:

[0031] a), preparation of sulfonyl chloride polystyrene cross-linked microspheres: in parts by weight, add 4.5 parts of polystyrene cross-linked microspheres with 5% cross-linking degree and four 72 parts of carbon chloride, stirred to fully swell the microspheres, slowly added 112.5 parts of chlorosulfonic acid at a controlled temperature of 20°C, raised the temperature to 50°C and kept it for 4 hours, and cooled down to 30°C for 8 hours after the reaction; Add 20mL of distilled water at ℃ to decompose excess chlorosulfonic acid until there is no large amount of HCl gas released in the solution; add 100mL of distilled water within 1h under stirring to make the product precipitate as much as possible, filter with suction, and use 1,4-bis Wash with hexane to remove residual solvent, then alternately wash with distilled water and ethanol for 3 to 5 times, filter to d...

Embodiment 3

[0034] A kind of sulfonamide allyl polystyrene cross-linked microspheres, its preparation steps are as follows:

[0035] a), preparation of sulfonyl chloride polystyrene cross-linked microspheres: in parts by weight, add 4 parts of polystyrene cross-linked microspheres with 8% cross-linking degree and 1 , 50 parts of 2-dichloroethane, stir to fully swell the microspheres, slowly add 160 parts of chlorosulfonic acid at a controlled temperature of 20°C, raise the temperature to 50°C and keep it warm for 5 hours, after the reaction, cool down to 30°C and let it stand for 8 hours ; Then add 40mL of distilled water at 20°C to decompose excess chlorosulfonic acid until there is no large amount of HCl gas released in the solution; add 120mL of distilled water within 1h under stirring to make the product precipitate as much as possible, filter with 1 , washed with 4-dioxane to remove the residual solvent, then alternately washed with distilled water and ethanol for 3 to 5 times, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com