Graphene anticorrosion flame-retardant coating

A flame retardant coating and graphene technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as environmental and human injury, and achieve the effects of preventing metal corrosion, good coating film leveling, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

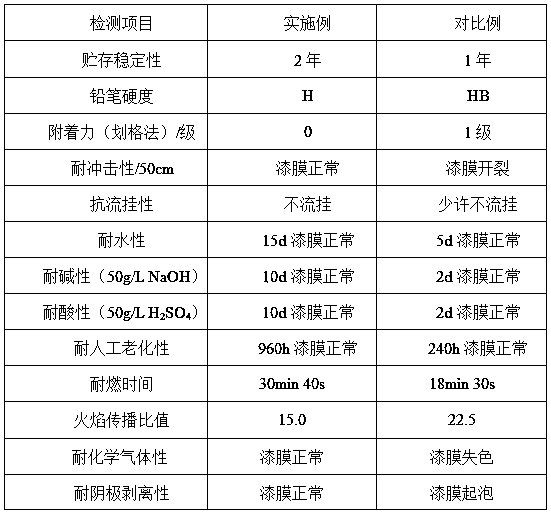

Examples

Embodiment 1

[0028] Melamine modified waterborne acrylic flame retardant resin X, its preparation process is as follows:

[0029] (1) Preparation of pre-emulsion: Add 5.0 parts of methyl acrylate, 10.0 parts of methyl methacrylate, 8.0 parts of butyl methacrylate, 3.5 parts of lauryl methacrylate and 2.0 parts of acrylic acid into the emulsification tank and stir to dissolve Transparent liquid, then add 2.2 parts of emulsifier and stir evenly, continue to add 21.0 parts of deionized water, and form a stable milky white oil-in-water pre-emulsion after stirring and dispersing;

[0030] (2) Preparation of initiator: dissolve 0.07 part of ammonium persulfate into 2.0 parts of deionized water and dissolve after stirring;

[0031] (3) Preparation of seed emulsion: Add 34.93 parts of deionized water into the reactor, and add 5.2 parts of pre-emulsion dropwise when heated to 78-82 ° C, and continue to drop 0.2 parts of initiator after the temperature in the reactor is stable ;

[0032] (4) Add t...

Embodiment 2

[0034] Melamine modified waterborne acrylic flame retardant resin Y, its preparation process is as follows:

[0035] (1) Preparation of pre-emulsion: Add 20.0 parts of methyl methacrylate, 14.0 parts of butyl methacrylate and 2.0 parts of acrylic acid into the emulsification tank in turn and stir to dissolve into a transparent liquid, then add 2.0 parts of emulsifier and stir evenly, continue to add 20.0 parts of ionized water, stirred and dispersed to form a stable milky white oil-in-water pre-emulsion;

[0036] (2) Preparation of initiator: dissolve 0.08 part of ammonium persulfate into 2.0 parts of deionized water and dissolve after stirring;

[0037](3) Preparation of seed emulsion: Add 27.62 parts of deionized water to the reactor, and add 5.8 parts of pre-emulsion dropwise when heated to 78-82 ° C, and continue to drop 0.2 parts of initiator after the temperature in the reactor is stable ;

[0038] (4) Add the remaining 52.2 parts of the pre-emulsion and 1.4 parts of t...

Embodiment 3

[0040] A graphene anti-corrosion flame-retardant coating, by weight, it is composed of melamine modified water-based acrylic flame-retardant resin X65.0 parts, nano carboxylate graphene 2.0 parts, titanium dioxide 5.0 parts, barium sulfate 3.5 parts, nano diamond beads 3.0 parts, 0.4 parts of wetting agent, 0.8 parts of dispersing agent, 0.2 parts of defoamer, 0.2 parts of leveling agent, 0.3 parts of thickener, 0.3 parts of pH regulator, 2.5 parts of film-forming aid, and 16.8 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com