Ferroelectric luminescent material and preparation method and application thereof

A luminescent material and ferroelectric technology, applied in the direction of luminescent materials, polycrystalline material growth, chemical instruments and methods, etc., can solve the problems of rare electrical regulation of luminescence performance and unreported regulation of single crystal luminescence performance, and achieve high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Example 1 ABO with luminescent ferroelectric properties 3 Preparation of perovskite crystal materials

[0085] The initial raw materials PbO, MgO, TiO 2 , Yb 2 o 3 , Nb 2 o 5 , PbO and B as cosolvent 2 o 3 Composite co-solvent, weighed according to the proportion, mixed and ground, and compounded; heated the compounded material to above the supersaturation temperature, kept the temperature for a period of time, and used the seed crystal to find the growth point to grow; grow at about 950-1100 ° C, and the crystal transformation The rate is 5-30rpm, and the cooling rate is 0.2-5°C per day; after the growth is over, the crystal is lifted out of the liquid level, and the cooling rate is 10-30°C per hour for cooling and annealing. The grown single crystal is a crystal with the (001) natural growth surface exposed, the crystal quality is good, and the composition uniformity is good. The sample number is P1 # , P2 # and P3 # , corresponding to Pb[Yb 0.05 Mg 0.20 ...

Embodiment 2

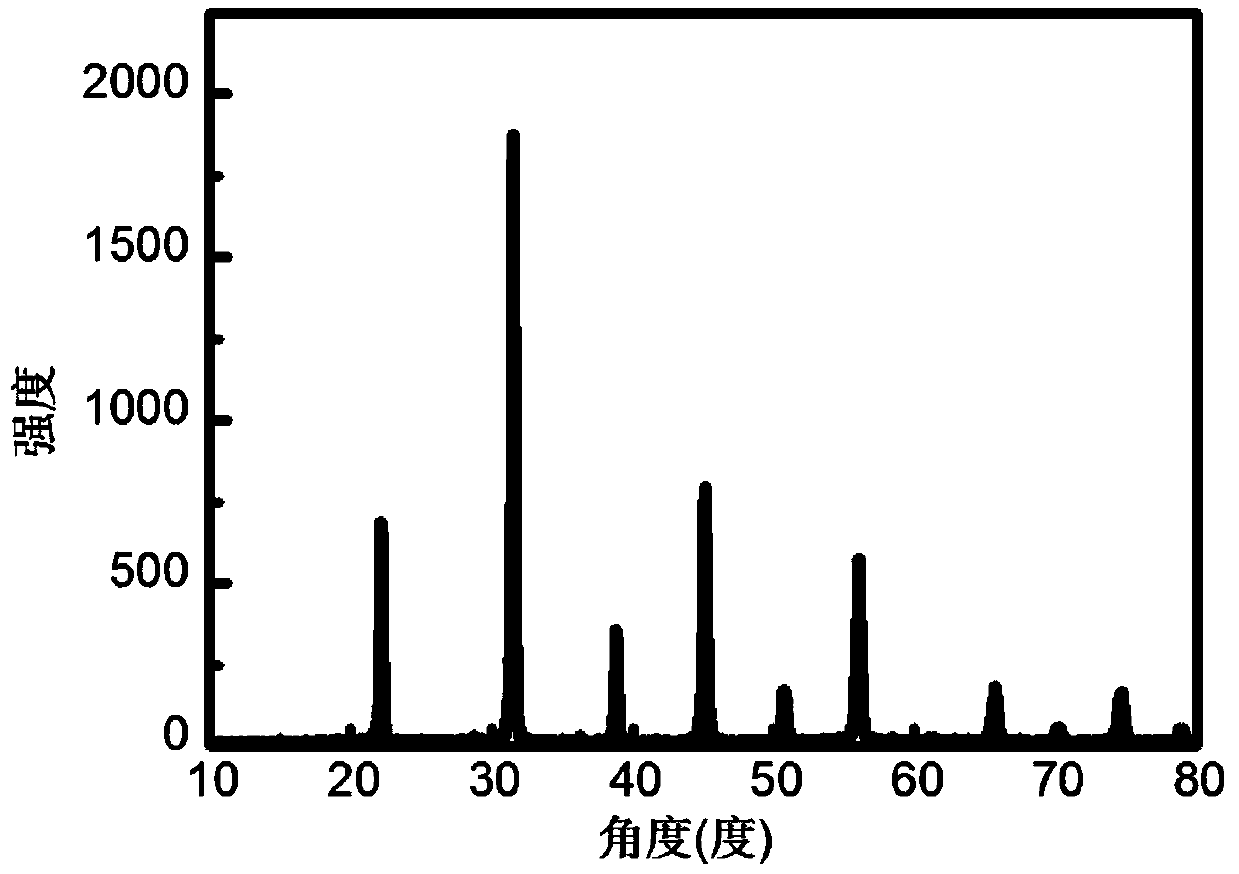

[0090] Example 2 Sample P1 # ~P3 # XRD diffraction data of

[0091] Sample P1 # ~P3 # Each was cut into a small piece and pulverized into powder, and subjected to X-ray powder diffraction analysis. The XRD diffraction pattern was compared with the X-ray diffraction standard card, and the results are shown in Table 2.

[0092] Table 2

[0093] Sample serial number

[0094] figure 1 for Pb[Yb 0.09 Mg 0.17 Nb 0.43 Ti 0.31 ]O 3 The X-ray powder diffraction pattern of the crystals shows that P2 # It is a trigonal perovskite structure. P1 # 、P3 # The X-ray powder diffraction pattern shows that P1 # It is a trigonal perovskite structure, P3 # It is a tetragonal perovskite structure.

Embodiment 3

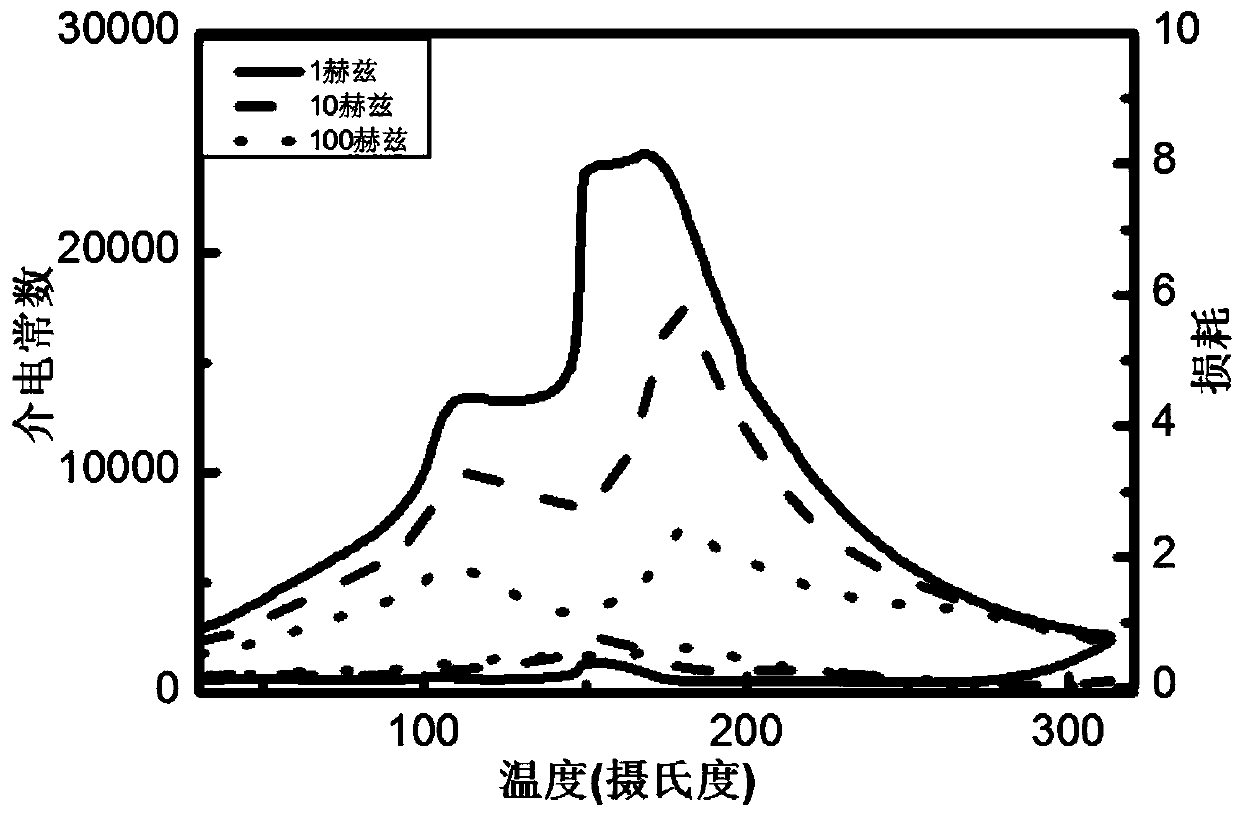

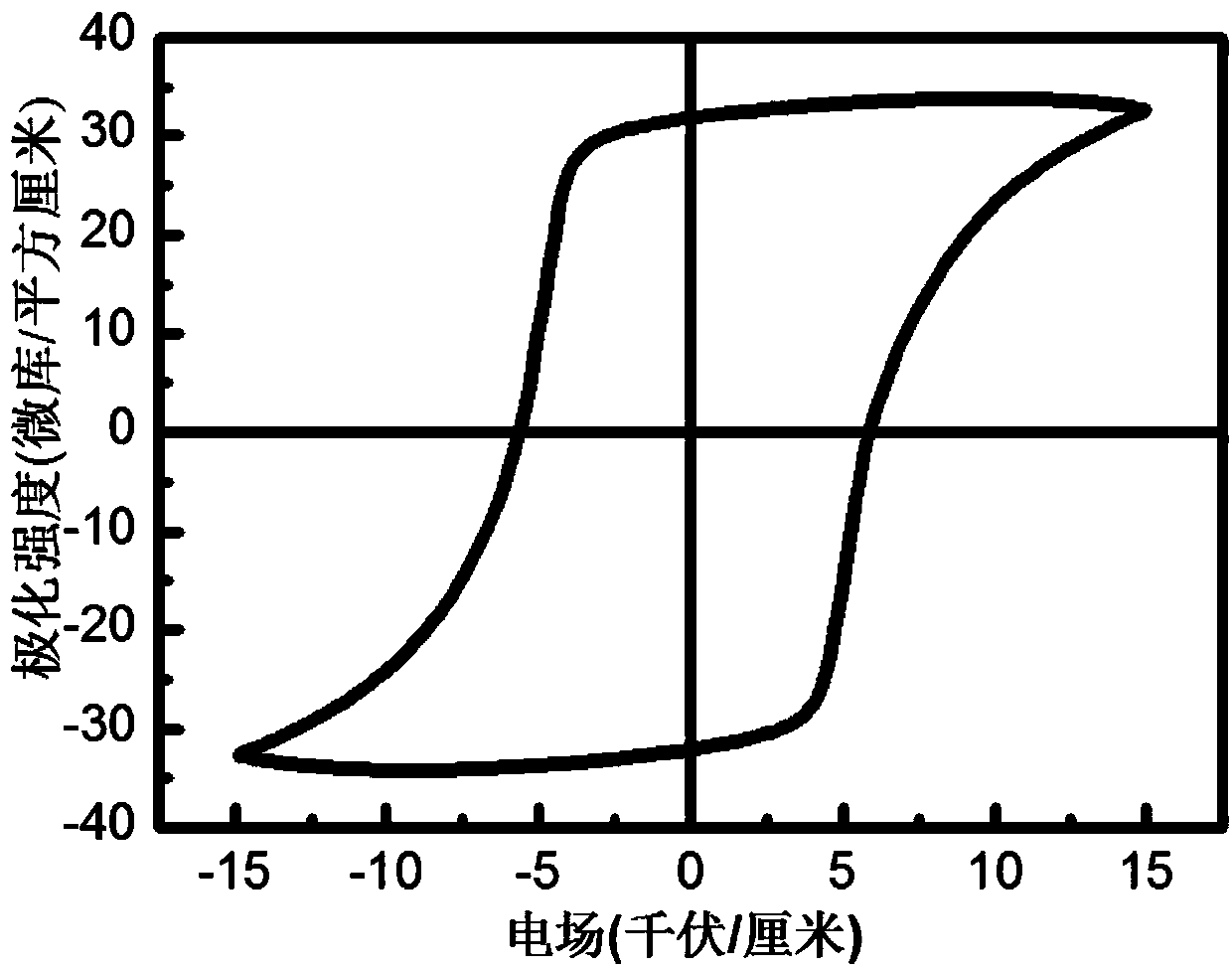

[0095] Example 3 Sample P1 # ~P3 # Determination of electrical properties of

[0096] The obtained ferroelectric crystal material sample P1 # ~P3 # Cut a small piece according to the [001] direction, and polish both sides of the slice smooth with different sandpaper. After grinding and coating silver electrodes on both sides, respectively for piezoelectric coefficient d 33 and hysteresis loop testing. The obtained piezoelectric coefficient d of each sample 33 as shown in Table 3. In the test results of the hysteresis loop, the coercive field E of each sample c , remanent polarization P r as shown in Table 3.

[0097] table 3

[0098]

[0099] It can be seen from Table 3 that the obtained materials all have high piezoelectric coefficients d 33 (290-2600pC / N), the Curie temperature is higher than 150°C, the coercive field can be adjusted in a relatively large range, and the remanent polarization is greater than 20μC / cm 2 , indicating good ferroelectric properties....

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com