Method for synthesizing low sulfur diesel anti-wear agent by one-step method

A technology of low-sulfur diesel oil and anti-wear agent, which is used in the petroleum industry, fuel additives, chemical recycling, etc., can solve problems such as diesel engine corrosion, and achieve the effects of increasing entanglement density, improving lubricity, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

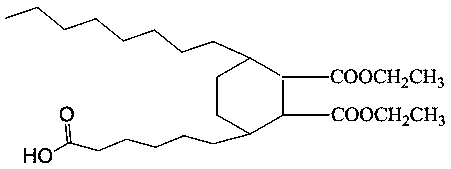

Image

Examples

Embodiment 1

[0029] Mesoporous alumina-supported nickel metal catalyst: Dissolve 18g triblock copolymer P123(EO)20(PO)70(EO)20 in 100ml ethanol solvent, mix well, then add 20g aluminum isopropoxide under stirring condition and 1.4g of nickel nitrate hexahydrate, continue to stir for 24h, dry at 60°C, heat up to 600°C at a rate of 2°C / min, and calcinate for 10h to obtain a mesoporous alumina-supported nickel catalyst.

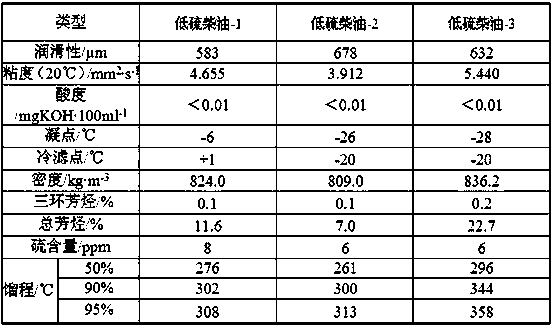

[0030] Mix 91.5g diethyl maleate, 100g soybean oil fatty acid (iodine value 130mgKOH / g), 15g mesoporous alumina-supported nickel catalyst, react at 200°C, 300rpm for 3h, and end the reaction. After the system was cooled to room temperature, the mesoporous alumina-supported nickel catalyst was removed by filtration, and the unreacted diethyl maleate and vegetable oil fatty acid were removed by vacuum distillation at a pressure of 65 Pa and 200°C for 2 hours to obtain the antiwear agent product A. The molecular conversion rate of soybean oil fatty acid was 55.1%. After testin...

Embodiment 2

[0033] The same catalyst as in Example 1 was used.

[0034] 123.8g of diethyl maleate, 100g of soybean oil fatty acid, and 20g of mesoporous alumina-supported nickel catalyst were mixed, reacted at 220°C and 300rpm for 2h, and then ended the reaction. After the system was cooled to room temperature, the mesoporous alumina-supported nickel catalyst was removed by filtration, and the unreacted diethyl maleate and vegetable oil fatty acid were removed by vacuum distillation at a pressure of 65 Pa and 200°C for 2 hours to obtain the antiwear agent product B. The molecular conversion rate of soybean oil fatty acid was 57.2%. After testing, the acid value of the product is 118.5mgKOH / g, and the freezing point is -26.7°C.

Embodiment 3

[0036] The same catalyst as in Example 1 was used.

[0037] 49.5g of diethyl maleate, 100g of soybean oil fatty acid, and 5g of mesoporous alumina-supported nickel catalyst were mixed, reacted at 180°C and 300rpm for 4h, and then ended the reaction. After the system was cooled to room temperature, the mesoporous alumina-supported nickel catalyst was removed by filtration, and the unreacted diethyl maleate and vegetable oil fatty acid were removed by vacuum distillation at a pressure of 65 Pa and 200°C for 2 hours to obtain the antiwear agent product C. The molecular conversion rate of soybean oil fatty acid was 50.6%. After testing, the acid value of the product is 123.2 mgKOH / g, and the freezing point is -25.5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com