Novel alkaline cyanide-free zinc plating additive

A galvanizing additive and alkaline technology, which is applied in the field of new alkaline cyanide-free galvanizing additives, can solve the problems of alkaline cyanide-free galvanizing technology lag, brittleness, insufficient depth capability, poor ductility, etc., and achieve small brittleness and brittleness Big, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

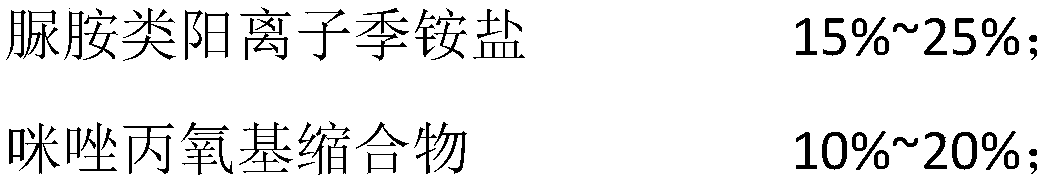

[0032] First configure 1L of additives, wherein the weight ratio of each component is 15% of urea amine cationic quaternary ammonium salt; 10% of imidazole propoxyl condensate; 4% of polyethyleneimine cationic quaternary ammonium salt; 0.8% salt; 1% modified aromatic aldehyde compound; 2.0% EDTA-2Na; 7.5% modified aromatic aldehyde sulfonate; the balance is pure water. First add the calculated amount of pure water into the reaction kettle, then add ureaamine cationic quaternary ammonium salt, imidazole propoxyl condensate, polyethyleneimine cationic quaternary ammonium salt, benzyl nicotinic acid ammonium salt, modified Sexual aromatic aldehyde compounds, EDTA-2Na, modified aromatic aldehyde sulfonates, stirred for 20 minutes until uniform without precipitation.

[0033] Configure 1L of plating solution so that the plating solution contains 10g of zinc oxide, 100g of sodium hydroxide, 10g of sodium carbonate, and 16ml of the above-mentioned additives, the temperature is 25°C, ...

Embodiment 2

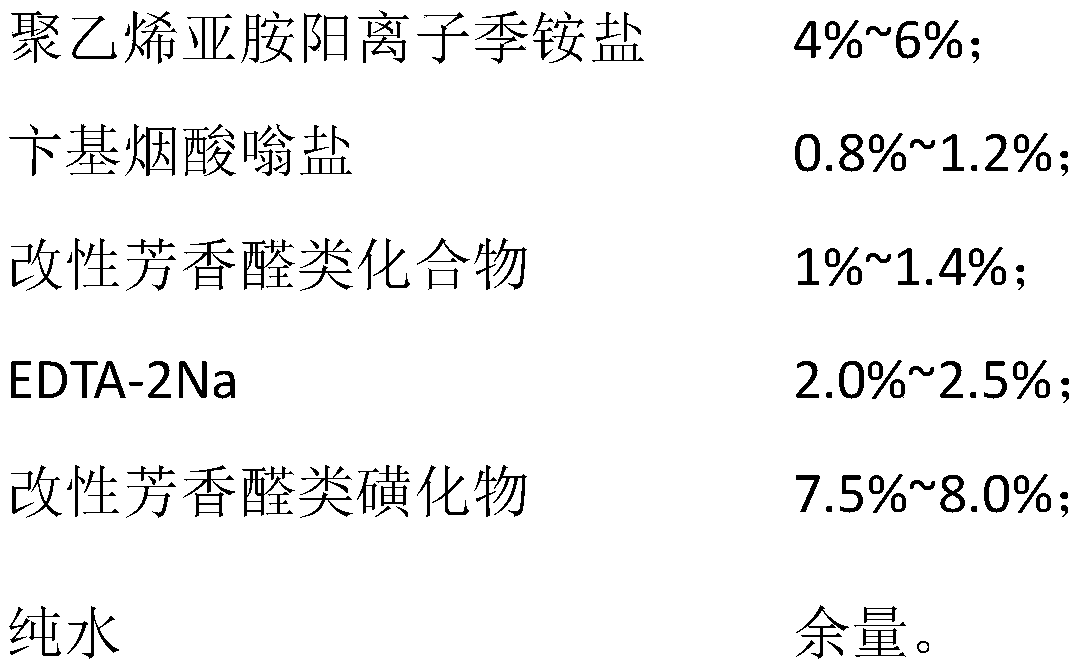

[0035]First configure 1L of additives, wherein the weight ratio of each component is 25% of urea amine cationic quaternary ammonium salt; 20% of imidazole propoxyl condensate; 6% of polyethyleneimine cationic quaternary ammonium salt; 1.2% salt; 1.4% modified aromatic aldehyde compound; 2.5% EDTA-2Na; 8% modified aromatic aldehyde sulfonate; the balance is pure water. First add the calculated amount of pure water into the reaction kettle, then add ureaamine cationic quaternary ammonium salt, imidazole propoxyl condensate, polyethyleneimine cationic quaternary ammonium salt, benzyl nicotinic acid ammonium salt, modified Sexual aromatic aldehyde compounds, EDTA-2Na, modified aromatic aldehyde sulfonates, stirred for 20 minutes until uniform without precipitation.

[0036] Configure 1L of plating solution so that the plating solution contains 11g of zinc oxide, 130g of sodium hydroxide, 10g of sodium carbonate, and 18ml of the above-mentioned additives, the temperature is 25°C, a...

Embodiment 3

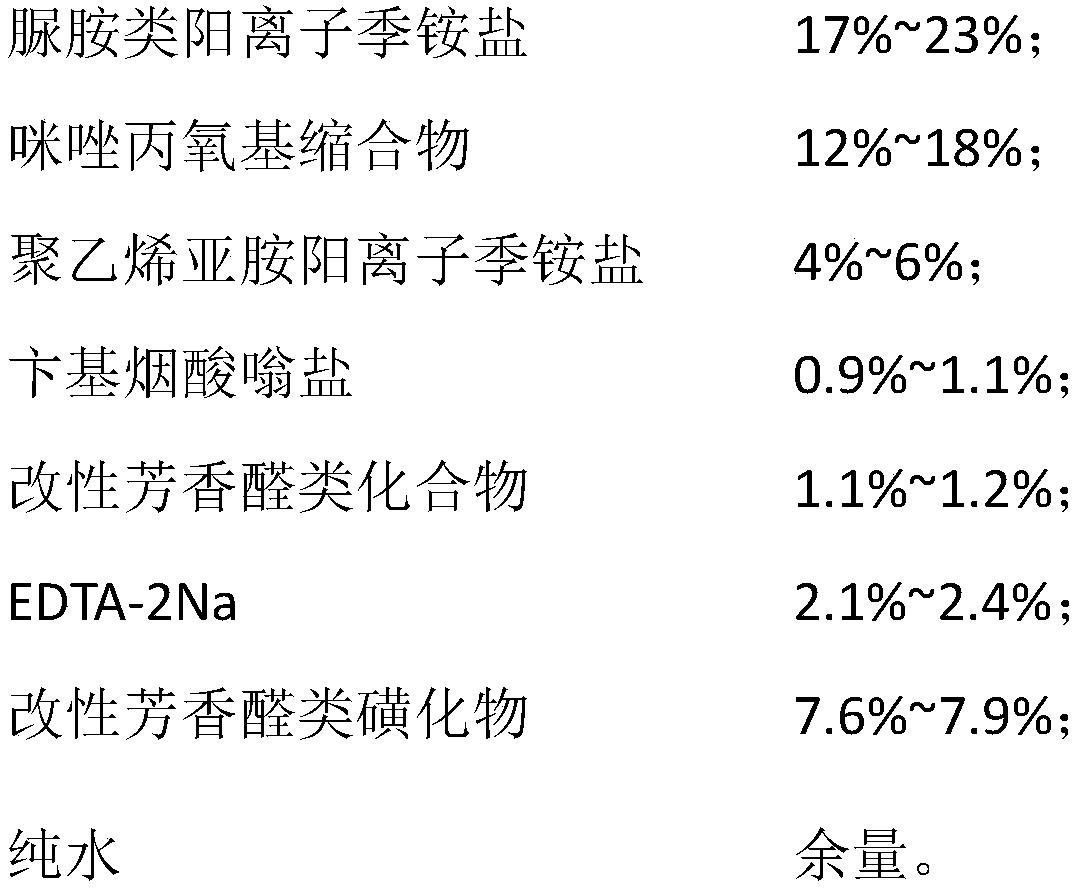

[0038] First configure 1L of additives, wherein the weight ratio of each component is 17% of urea amine cationic quaternary ammonium salt; 12% of imidazole propoxyl condensate; 4% of polyethyleneimine cationic quaternary ammonium salt; 0.9% of salt; 1.1% of modified aromatic aldehyde compounds; 2.1% of EDTA-2Na; 7.6% of modified aromatic aldehyde sulfonates; the balance is pure water. First add the calculated amount of pure water into the reaction kettle, then add ureaamine cationic quaternary ammonium salt, imidazole propoxyl condensate, polyethyleneimine cationic quaternary ammonium salt, benzyl nicotinic acid ammonium salt, modified Sexual aromatic aldehyde compounds, EDTA-2Na, modified aromatic aldehyde sulfonates, stirred for 18 minutes until uniform without precipitation.

[0039] Configure 1L of plating solution so that the plating solution contains 12g of zinc oxide, 140g of sodium hydroxide, 50g of sodium carbonate, 20ml of the above additives, the temperature is 25°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com