Method for preparing gas diffusion layer of proton exchange membrane fuel cell

A gas diffusion layer and proton exchange membrane technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost of gas diffusion layers, limited application range, low conductivity, etc., and achieve superior battery performance and abundant sources. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

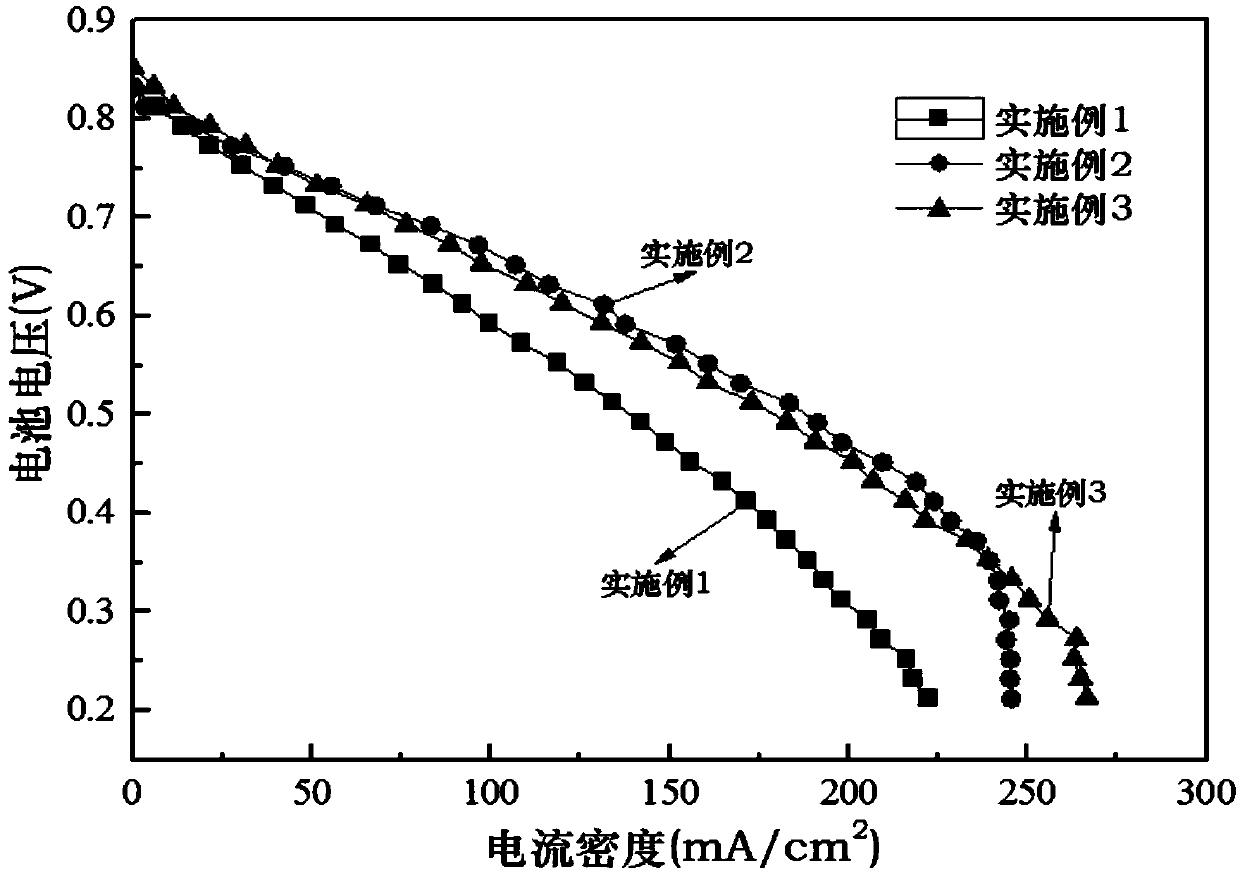

Embodiment 1

[0035] First cut the log into slices perpendicular to the growth direction of the tree, scrape and trim the bark on the periphery of the log, and dry it in an oven at 50°C for 24 hours; place the dried log in a muffle furnace and pre-heat it at 240°C Carbonize for 10 hours; place the pre-carbonized carbonized wood in a tube furnace, and carbonize for 1 hour at 1000°C in a nitrogen-filled environment; Soak the carbonized wood and ultrasonically disperse and clean the carbon powder remaining on the carbonized wood, place it in an oven to dry and weigh it; dilute the PTFE emulsion with a mass fraction of 60% with deionized water to obtain a water-repellent emulsion with a mass fraction of 5%; Soak the dried carbonized wood with 5% PTFE emulsion in turn, ultrasonically disperse for 10 minutes, dry and weigh until the load of PTFE emulsion accounts for 30% of the carbonized wood mass; place the soaked carbonized wood in a tube furnace Sinter at 375°C for 1 hour under a nitrogen-fil...

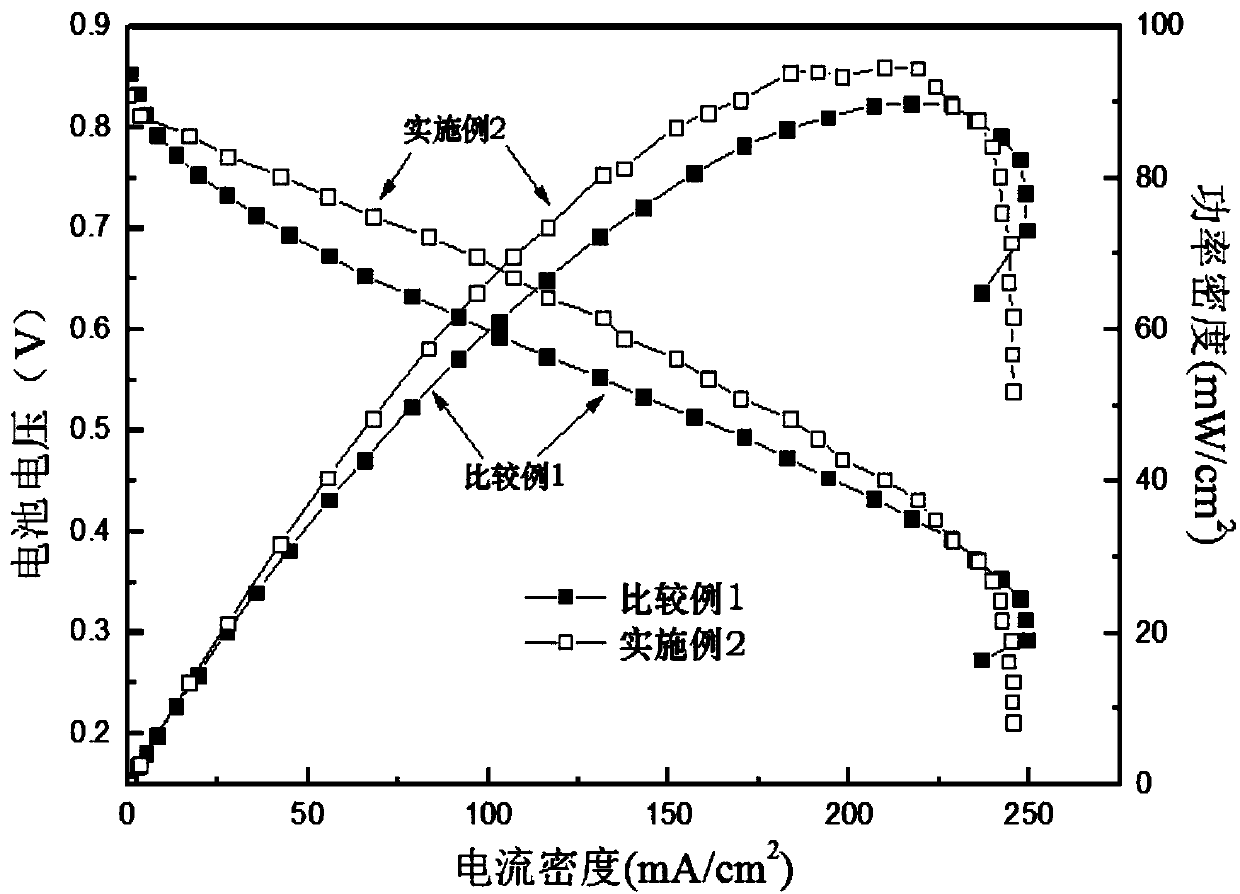

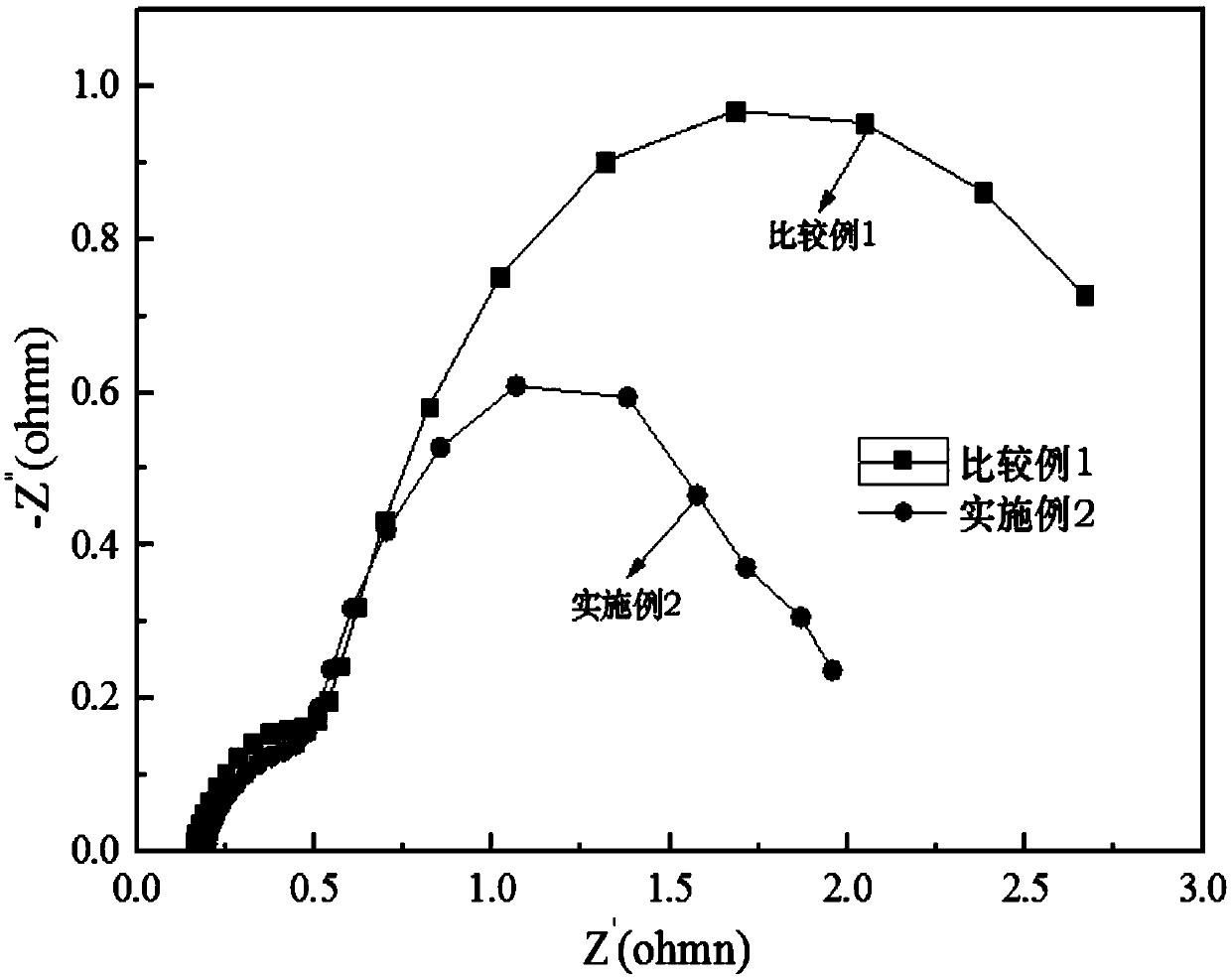

Embodiment 2

[0037] First cut the log into slices perpendicular to the growth direction of the tree, scrape and trim the bark on the periphery of the log, and dry it in an oven at 50°C for 24 hours; place the dried log in a muffle furnace and pre-heat it at 240°C. Carbonize for 10 hours; place the pre-carbonized carbonized wood in a tube furnace, and carbonize for 1 hour at 1000°C in a nitrogen-filled environment; Soak the carbonized wood and ultrasonically disperse and clean the carbon powder remaining on the carbonized wood, place it in an oven to dry and weigh it; dilute the PTFE emulsion with a mass fraction of 60% with deionized water to obtain a water-repellent emulsion with a mass fraction of 5%; Soak the dried carbonized wood with 5% PTFE emulsion in turn, ultrasonically disperse for 10 minutes, dry and weigh until the load of PTFE emulsion accounts for 20% of the mass of carbonized wood; place the soaked carbonized wood in a tube furnace Sinter at 375°C for 1 hour under a nitrogen...

Embodiment 3

[0039]First cut the log into slices perpendicular to the growth direction of the tree, scrape and trim the bark around the log, and dry it in an oven at 50°C for 24 hours; place the dried log in a muffle furnace for pre-carbonization at 240°C 10 hours; place the pre-carbonized carbonized wood in a tube furnace, and carbonize it at 1000°C for 1 hour in a nitrogen-filled environment; trim the carbonized wood to 0.3mm with a cutting tool, and soak it in absolute ethanol The carbonized wood is ultrasonically dispersed and cleaned to clean the remaining carbon powder on the carbonized wood, placed in an oven to dry and weighed; the PTFE emulsion with a mass fraction of 60% is diluted with deionized water to obtain a water-repellent emulsion with a mass fraction of 5%; Soak the dried carbonized wood with 5% PTFE emulsion, ultrasonically disperse for 10 minutes, dry and weigh until the load of PTFE emulsion accounts for 10% of the mass of carbonized wood; place the soaked carbonized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com