Preparation process for high-stability prinsepia utilis royle liposome and application of high-stability prinsepia utilis royle liposome in cosmetics

A technology for the preparation of oily liposomes, which is applied in the field of carrier systems, can solve the problems of uneven particle size distribution of liposomes, low encapsulation efficiency of active substances, general stability, etc., so as to improve bioavailability, improve encapsulation The sealing rate and stability, and the effect of promoting human body absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

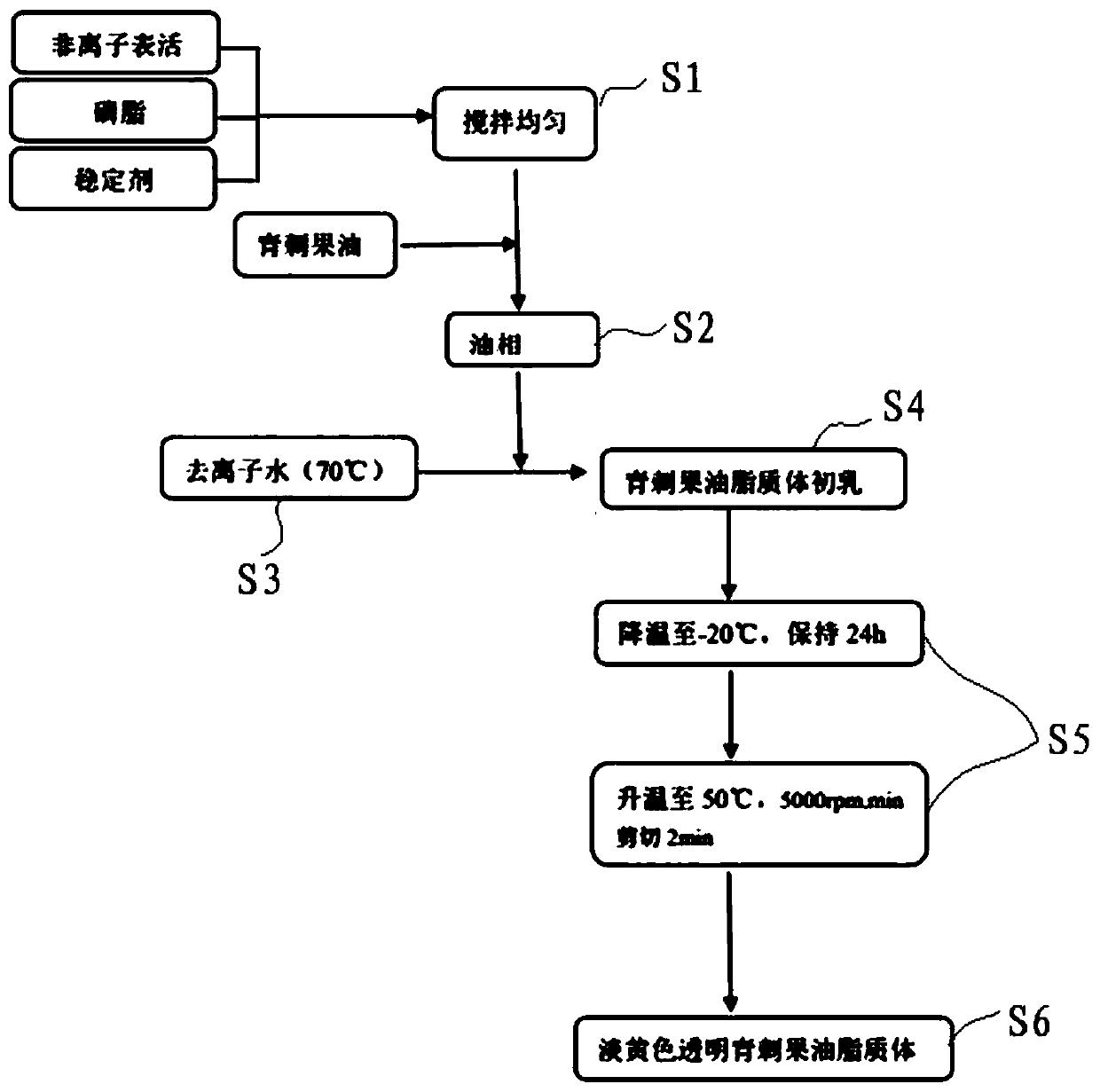

[0034] see figure 1 with figure 2 , a kind of preparation technology of highly stable thorn fruit oil liposome, comprises the following steps:

[0035]S1, 14 parts of lecithin, 55 parts of glycerol (stabilizer) and 1 part of cholesterol (stabilizer) were added to the container respectively, and the eggs were stirred at 70°C and 200 rpm / min. Phospholipids, glycerol and cholesterol are mixed and dissolved evenly;

[0036] S2, adding 9 parts of green thorn fruit oil to the mixed solution obtained in step S1, and stirring evenly under the temperature condition of 60° C. and the stirring condition of 200 rpm / min to obtain the oil phase;

[0037] S3, heating 21 parts of deionized water to 70°C to obtain an aqueous phase;

[0038] S4, inject the oil phase obtained in step S2 into the water phase obtained in step S3, and shear at a shear rate of 5000 rpm / min at a temperature of 70°C and a stirring condition of 200 rpm / min to obtain a semi-transparent and viscous Liposome colostru...

Embodiment 2

[0042] see figure 1 and figure 2 , a kind of preparation technology of highly stable thorn fruit oil liposome, comprises the following steps:

[0043] S1, add 12 parts of lecithin, 12 parts of sorbitol (stabilizer), 26 parts of glycerol (stabilizer) and 1 part of polyglycerol 10-stearate (nonionic surfactant) In the container, mix and dissolve lecithin, sorbitol, glycerol and polyglycerol 10-stearate evenly under the temperature condition of 65° C. and the stirring condition of 200 rpm / min;

[0044] S2, adding 15 parts of thorn fruit oil to the mixed solution obtained in step S1, and stirring evenly under the temperature condition of 70° C. and the stirring condition of 200 rpm / min to obtain the oil phase;

[0045] S3, heating 34 parts of deionized water to 70°C to obtain an aqueous phase;

[0046] S4, inject the oil phase obtained in step S2 into the water phase obtained in step S3, and shear at a shear rate of 5000 rpm / min at a temperature of 70°C and a stirring conditio...

Embodiment 3

[0050] see figure 1 and figure 2 , a kind of preparation technology of highly stable thorn fruit oil liposome, comprises the following steps:

[0051] S1, 6 parts of lecithin, 30.5 parts of pentaerythritol (stabilizer), 1 part of phytosphingosine (stabilizer), 20 parts of butanediol (stabilizer) and 0.5 parts of Span 60 (nonionic Surfactants) were added in the container respectively, and the lecithin, pentaerythritol, phytosphingosine, butanediol and Span 60 were mixed and dissolved evenly under the temperature condition of 65° C. and the stirring condition of 200 rpm / min;

[0052] S2, adding 5 parts of green thorn fruit oil to the mixed solution obtained in step S1, stirring evenly at a temperature of 70°C and a stirring condition of 200rpm / min to obtain an oil phase;

[0053] S3, heating 37 parts of deionized water to 70°C to obtain an aqueous phase;

[0054] S4, inject the oil phase obtained in step S2 into the water phase obtained in step S3, and shear at a shear rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com