ZnIn2S4 nano-sheet coated beta-Bi2O3 core-shell heterogeneous compound photocatalyst, as well as preparation method and application thereof

A -bi2o3, znin2s4 technology, which is applied in the preparation of inorganic photocatalytic nanocomposite materials and the treatment of environmental water pollution, and achieves the effects of mild reaction conditions, simple operation and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

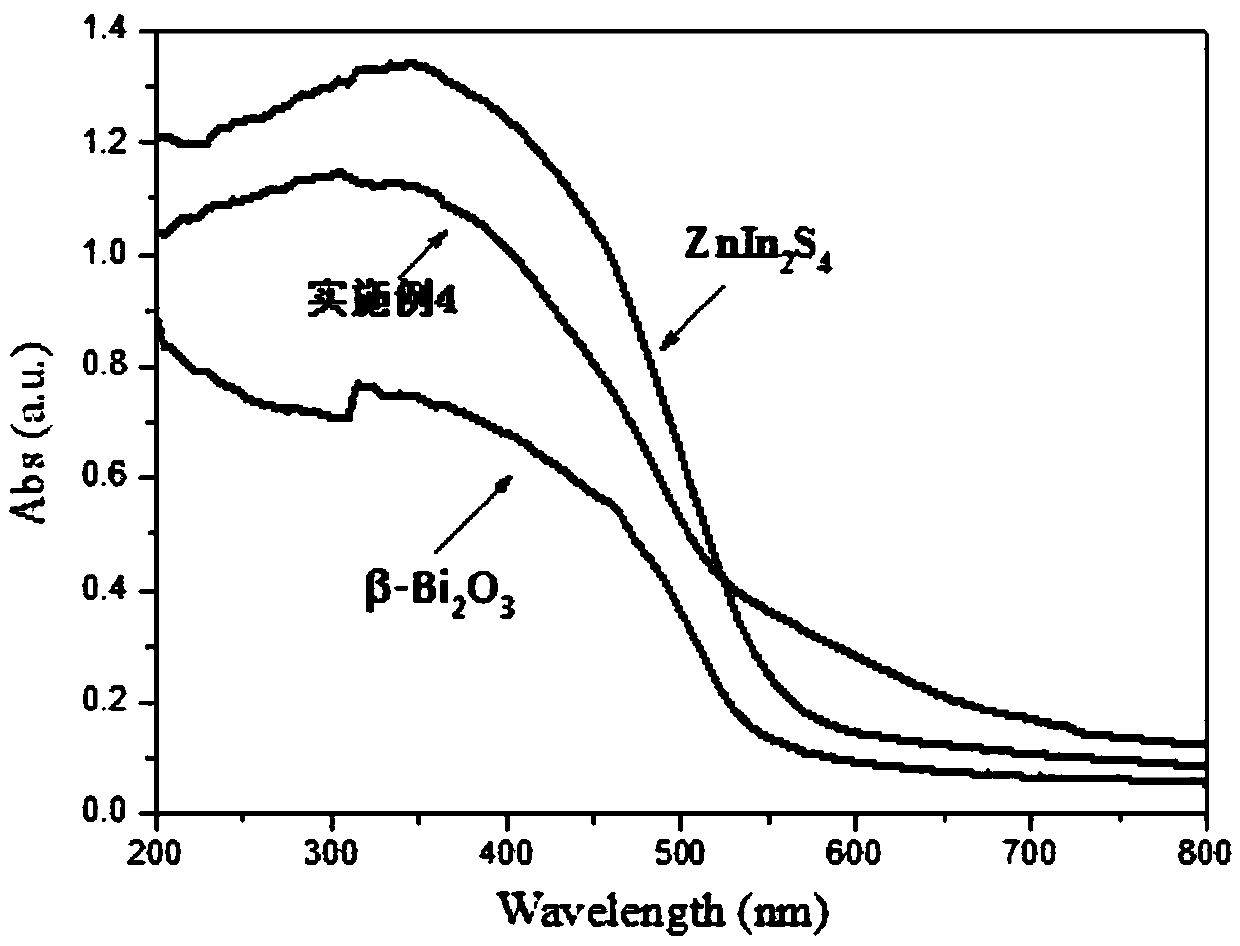

[0023] (1) Weigh 0.1617g Bi(NO 3 ) 3 ·5H 2 O, 0.0601g of D-fructose, dissolved in 25ml of ethylene glycol solvent, stirred for 10min to obtain a mixed suspension, then transferred to a reaction kettle for constant temperature reaction, the temperature was 140°C, the time was 10h, and the reaction ended After cooling to room temperature, the resulting product was centrifuged and washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain β-Bi 2 o 3 Precursor. Put it into a tube furnace, heat up at a rate of 2°C / min, and calcinate at 200°C for 0.5h. After the reaction is over, cool to room temperature to obtain β-Bi 2 o 3 monomer.

[0024] (2) Measure 10ml methanol solution respectively, add 0.025g ZnIn 2 S 4 and 0.475g β-Bi 2 o 3 , ultrasonication for 3 minutes, stirring for 5 minutes, repeated six times to obtain its dispersion. Afterwards, with stirring, the ZnIn 2 S 4 The dispersion was added dropwise to β-Bi 2 o 3 in the disp...

Embodiment 2

[0027] (1) Weigh 0.2079g Bi(NO 3 ) 3 ·5H 2 O, 0.0772g D-fructose, dissolved in 30ml of ethylene glycol solvent, stirred for 15min to obtain a mixed suspension, then transferred it to a reaction kettle, and carried out constant temperature reaction, the temperature was 160°C, the time was 12h, and the reaction ended After cooling to room temperature, the resulting product was centrifuged and washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain β-Bi 2 o 3 Precursor. Put it into a tube furnace, heat up at a rate of 2°C / min, and calcinate at 250°C for 0.5h. After the reaction, cool to room temperature to obtain β-Bi 2 o 3 monomer.

[0028] (2) Measure 10ml methanol solution respectively, add 0.09g ZnIn 2 S 4 and 0.91g β-Bi 2 o 3 , sonicated for 5 minutes, stirred for 8 minutes, and repeated six times to obtain its dispersion. Afterwards, with stirring, the ZnIn 2 S 4 The dispersion was added dropwise to β-Bi 2 o 3 in the disp...

Embodiment 3

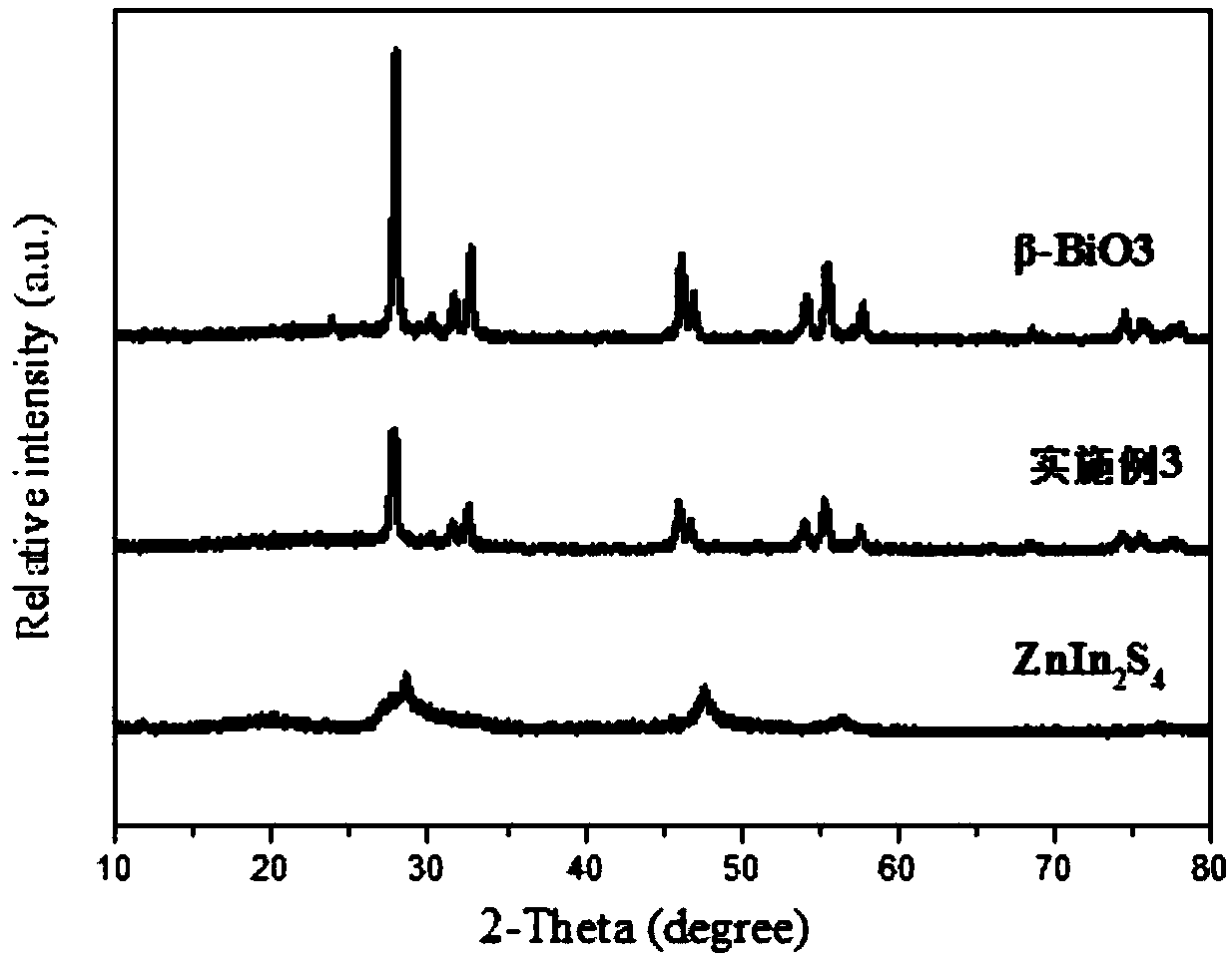

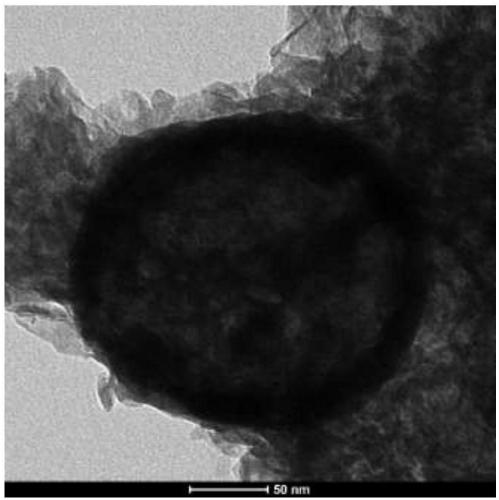

[0031] (1) Weigh 0.7276g Bi(NO 3 ) 3 ·5H 2 O, 0.2707g D-fructose, dissolved in 35ml of ethylene glycol solvent, obtained a mixed suspension by stirring for 25min, and then transferred it to a reaction kettle for constant temperature reaction, the temperature was 160°C, the time was 15h, and the reaction ended After cooling to room temperature, the resulting product was centrifuged and washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain β-Bi 2 o 3 Precursor. Put it into a tube furnace, heat up at a rate of 3°C / min, and calcinate at 300°C for 1 hour. After finishing, cool to room temperature to obtain β-Bi 2 o 3 monomer.

[0032] (2) Measure 15ml methanol solution respectively, add 0.144g ZnIn 2 S 4 and 1.056 g β-Bi 2 o 3 , ultrasonication for 8 minutes, stirring for 10 minutes, repeated six times to obtain its dispersion. Afterwards, with stirring, the ZnIn 2 S 4 The dispersion was added dropwise to β-Bi 2 o 3 in the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com