Method for preparing Prussian blue positive electrode material and sodium ion battery

A cathode material, Prussian blue technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high lattice vacancy and water content, poor crystal integrity, poor cycle performance, etc., to reduce water content and Effects of vacancy content, good cycle stability, and complete crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The precursor solution required for this reaction is 0.01 mol L-1 Na4Fe(CN)6 and FeCl2 aqueous solution. The specific steps are:

[0032] 1) Take a certain amount of sodium ferrocyanide decahydrate and ferrous chloride tetrahydrate, and dissolve them in deionized water added with a small amount of ascorbic acid and Ketjen black, respectively, to form a precursor solution with a concentration of 0.01mol L-1;

[0033] 2) Before deposition, ultrasonically clean the substrate;

[0034] 3) Flow the two solutions to the spray head at a constant speed of 3mL h-1, control the temperature of the substrate at 100°C, adjust the distance from the needle to the substrate to 3cm, and adjust the DC voltage between the spray head and the substrate to 15kV, Obtain uniform and stable aerosol spray between the nozzle and the substrate, control the spray time to 200min, and obtain the Prussian blue complex film material on the substrate

[0035] Result detection:

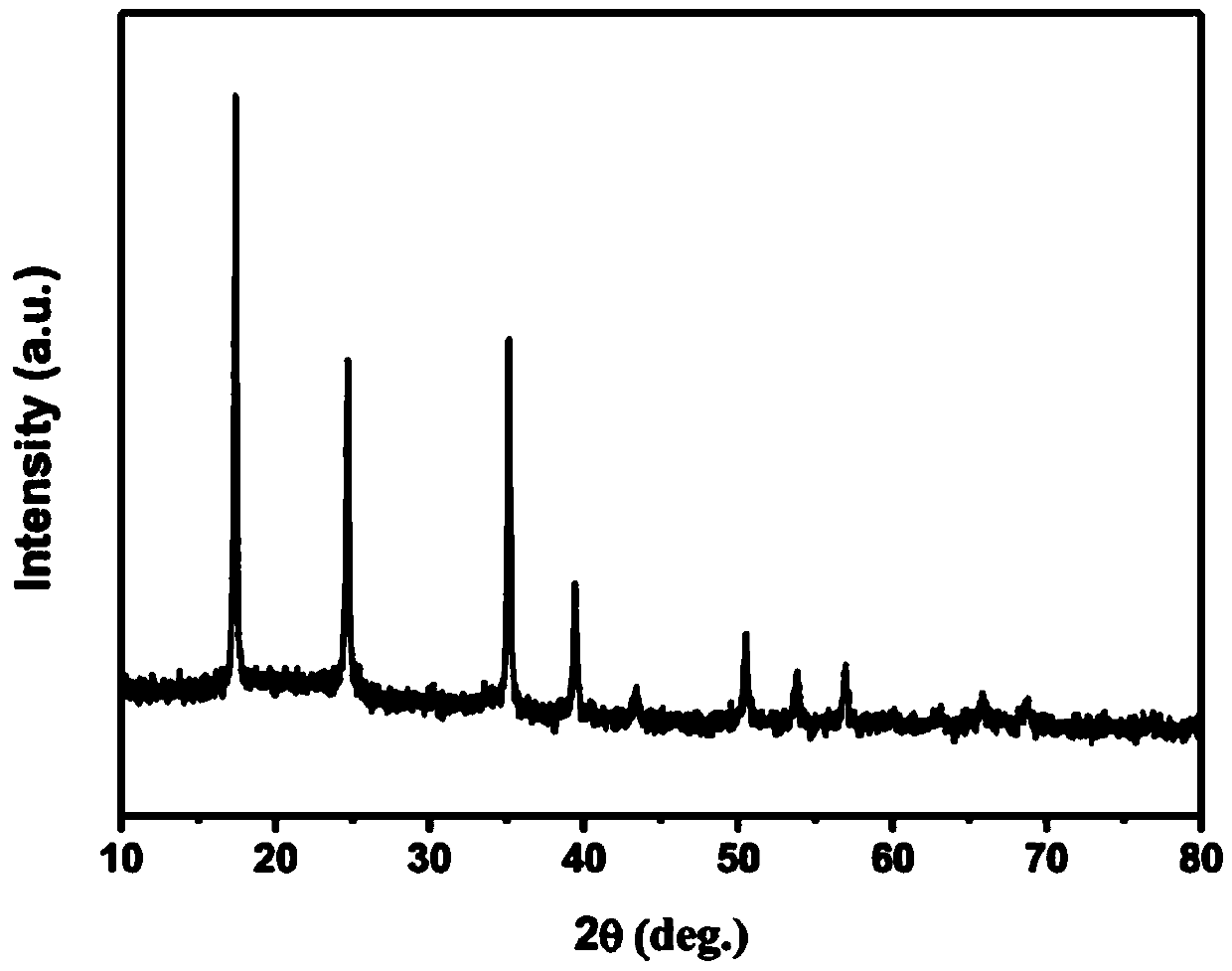

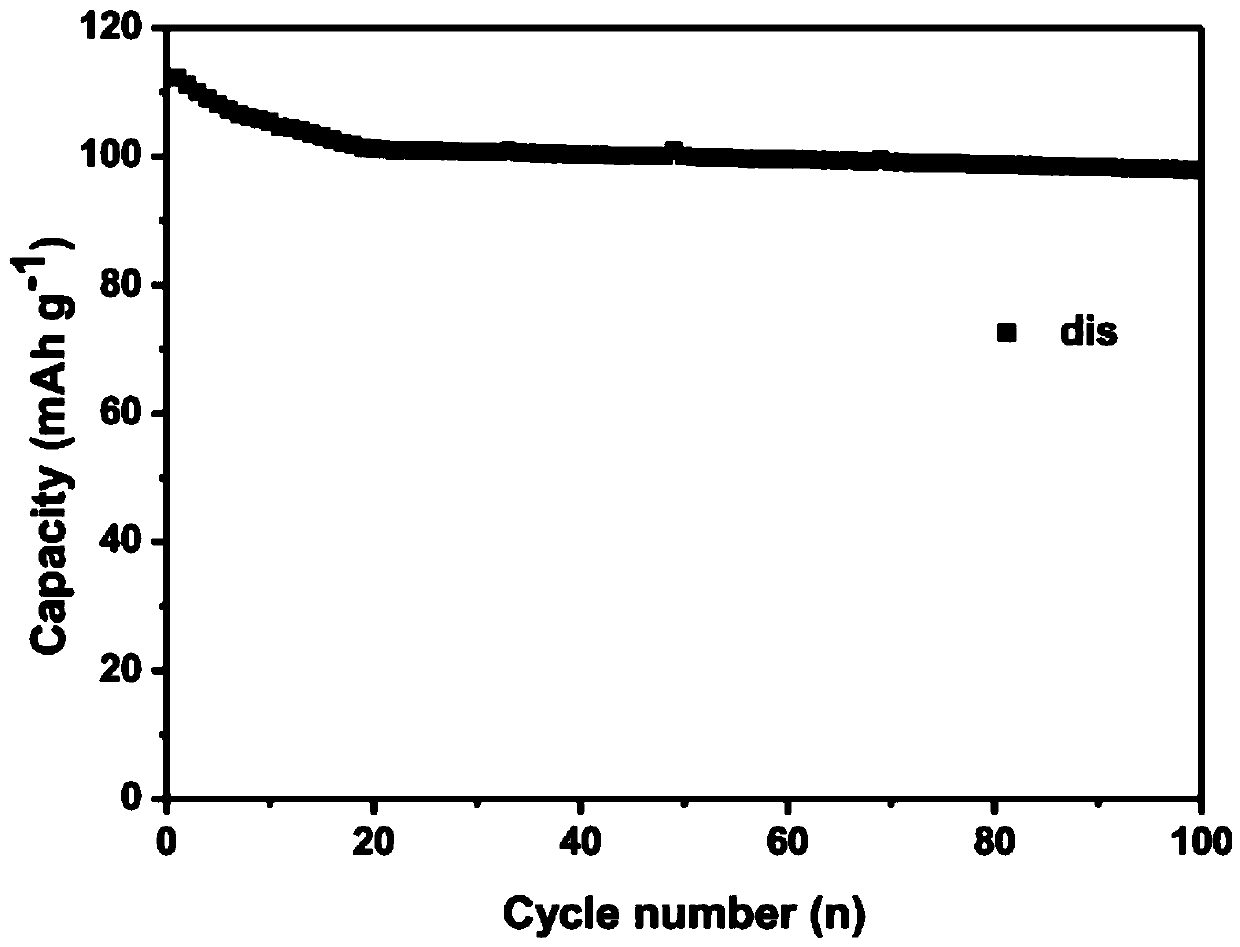

[0036] 1. Adopt powde...

Embodiment 2

[0043] The preparation method of this embodiment is the same as that of Example 1, but the reducing agent is sodium borohydride. Wherein the precursor solution required for the reaction is 0.01mol L-1 Na4Fe(CN)6 and MnCl2 aqueous solution. The specific steps are:

[0044] 1) Take a certain amount of sodium ferrocyanide decahydrate and manganese chloride tetrahydrate, and dissolve them in deionized water with a small amount of sodium borohydride and Ketjen black, respectively, to form a precursor solution with a concentration of 0.01mol L-1 ;

[0045] 2) Before deposition, ultrasonically clean the substrate;

[0046] 3) Flow the two solutions to the spray head at a constant speed of 3mL h-1, control the temperature of the substrate at 100°C, adjust the distance from the needle to the substrate to 3cm, and adjust the DC voltage between the spray head and the substrate to 15kV, A uniform and stable aerosol spray is obtained between the nozzle and the substrate, and the sprayin...

Embodiment 3

[0049] The preparation method of this embodiment is the same as that of Example 1, but the reducing agent is sodium borohydride. Wherein the precursor solution required for the reaction is 0.02mol L-1 Na4Fe(CN)6 and CoCl2 aqueous solution. The specific steps are:

[0050] 1) Take a certain amount of sodium ferrocyanide decahydrate and cobalt chloride hexahydrate, and dissolve them in deionized water with a small amount of sodium borohydride and Ketjen black, respectively, to form a precursor solution with a concentration of 0.02mol L-1 ;

[0051] 2) Before deposition, ultrasonically clean the substrate;

[0052] 3) Flow the two solutions to the spray head at a constant speed of 4mL h-1, control the temperature of the substrate at 140°C, adjust the distance from the needle to the substrate to 4cm, and adjust the DC voltage between the spray head and the substrate to 17kV, A uniform and stable aerosol spray is obtained between the nozzle and the substrate, and the spray time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com