Dissolution preparation process of a coal-fired flue gas denitrification agent

A coal-fired flue gas and preparation process technology, applied in the direction of gas treatment, separation methods, and dispersed particle separation, can solve the problems of reducing denitrification efficiency, consuming large energy, blocking denitrification, etc., so as to avoid denitrification efficiency, reduce energy consumption, The effect of accelerating ion motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] The dissolution preparation process of the coal-fired flue gas denitrification agent proposed by the present invention specifically includes arranging an alternating magnetic field and a permanent magnetic field around the sizing pipe of the denitrification process injection device, and under the combined action of stirring and magnetic field environment, the urea crystal is accelerated. The method of dissolving, and further dissolving and preparing the denitrification agent for coal-fired flue gas, the laboratory plan includes: setting up a constant magnetic field device and an alternating magnetic field device, and then placing urea taken from the factory in different magnetic fields for dissolution experiments.

[0046] (1) Setting of constant magnetic field device

[0047] Bind 6 to 18 iron cores on the side wall of a stainless steel container with a diameter of 32mm. The iron core specification is 2.5mm thick rare earth permanent magnets, such as magnetic tiles and ...

Embodiment 1

[0053] (1) Setting of constant magnetic field device

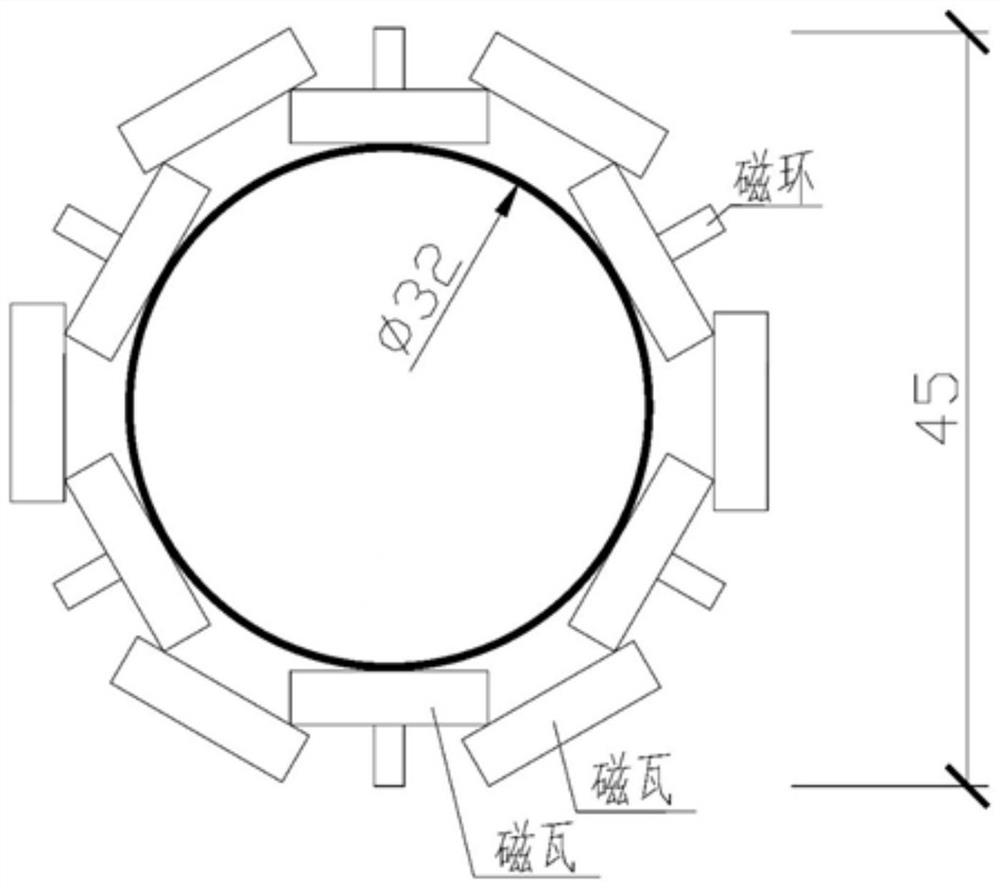

[0054] Bind 18 iron cores on the side wall of a stainless steel container with a diameter of 32mm. The iron core specification is a rare earth permanent magnet with a thickness of 2.5mm, such as magnetic tiles and magnetic rings. The width of the iron core is 5mm and the height is 4mm. At this time, the magnetic field strength is 900GS. The Gauss meter is used for testing, and the schematic diagram of the constant magnetic field device is shown in figure 1 shown;

[0055] (2) Setting of alternating magnetic field device

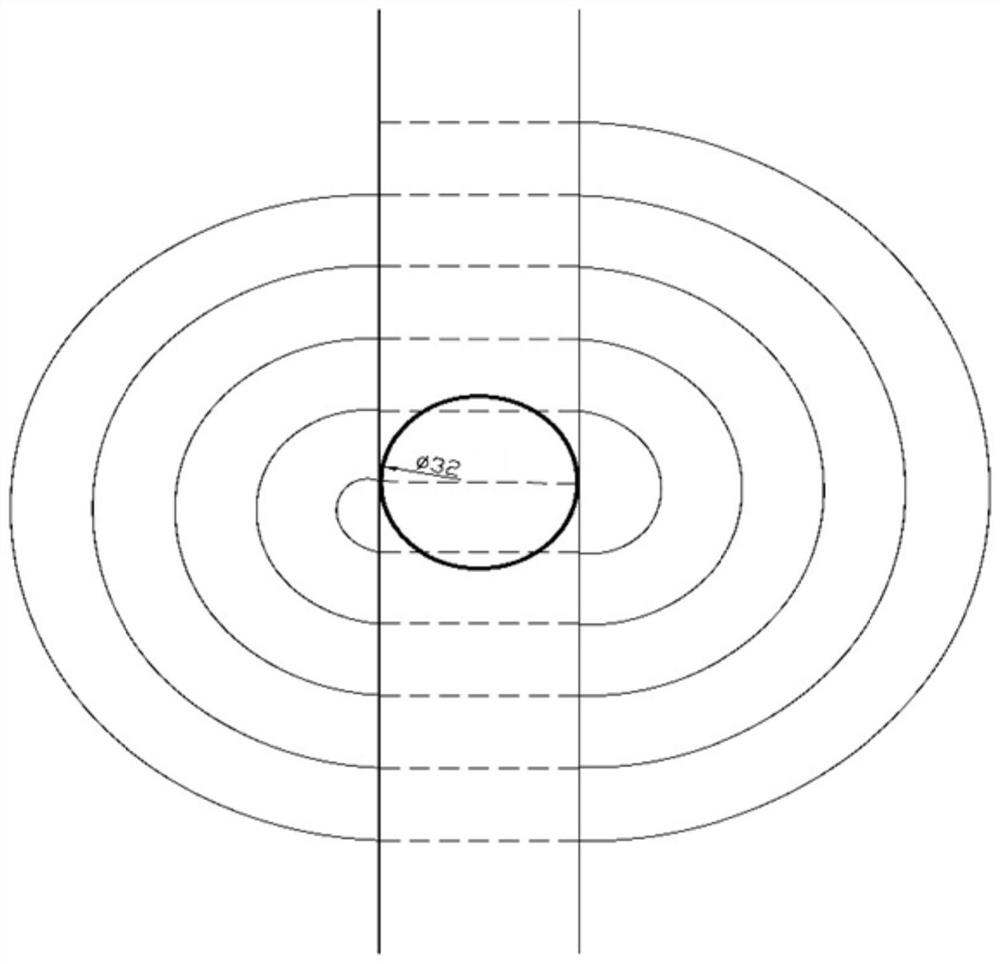

[0056] Use commercial power (50Hz) for alternating magnetic field setting, connect the solenoid lead-out line of the above-mentioned constant magnetic field generator to the voltage regulating transformer, adjust the voltage frequency output by the commercial power to adjust the magnetic field strength of the magnetic field to be the same as that of the constant magnetic field , both are 900GS, and test...

Embodiment 2

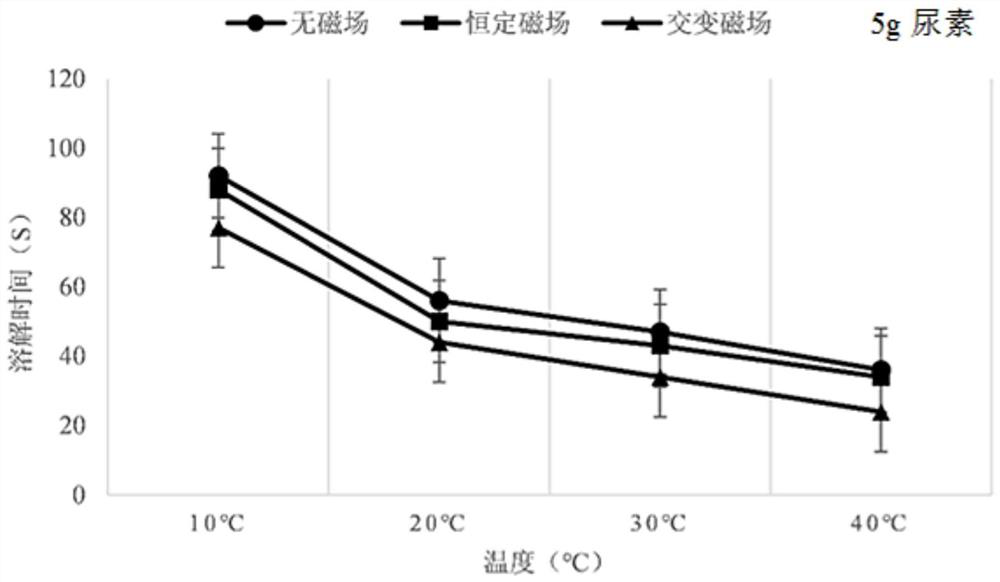

[0063] Same as Example 1, but different from Example 1, the consumption of urea is respectively 10~20g. Under the conditions of no magnetic field, constant magnetic field and alternating magnetic field, the schematic diagram of the time required for the complete dissolution of urea as a function of temperature is shown in Figure 4-6 .

[0064] The change diagram of temperature difference before and after 5g urea dissolves in embodiment 1 is as Figure 7 As shown, the schematic diagram of the change of temperature difference before and after dissolution of different masses of urea under the action of alternating magnetic field is as follows Figure 8 shown.

[0065] From Figure 3-6 It can be seen that the irregular thermal motion of urea solution molecules becomes more and more intense with the continuous increase of the magnetic field effect for the same mass of urea, that is to say, the Brownian motion becomes more and more intense, and the dissolution time becomes faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com