A preparation method and application of modified rice straw biochar

A technology of rice straw and biochar, which is applied to chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of easy aggregation of particles, high price, toxicity, etc., to increase specific surface area, improve adsorption efficiency, increase The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

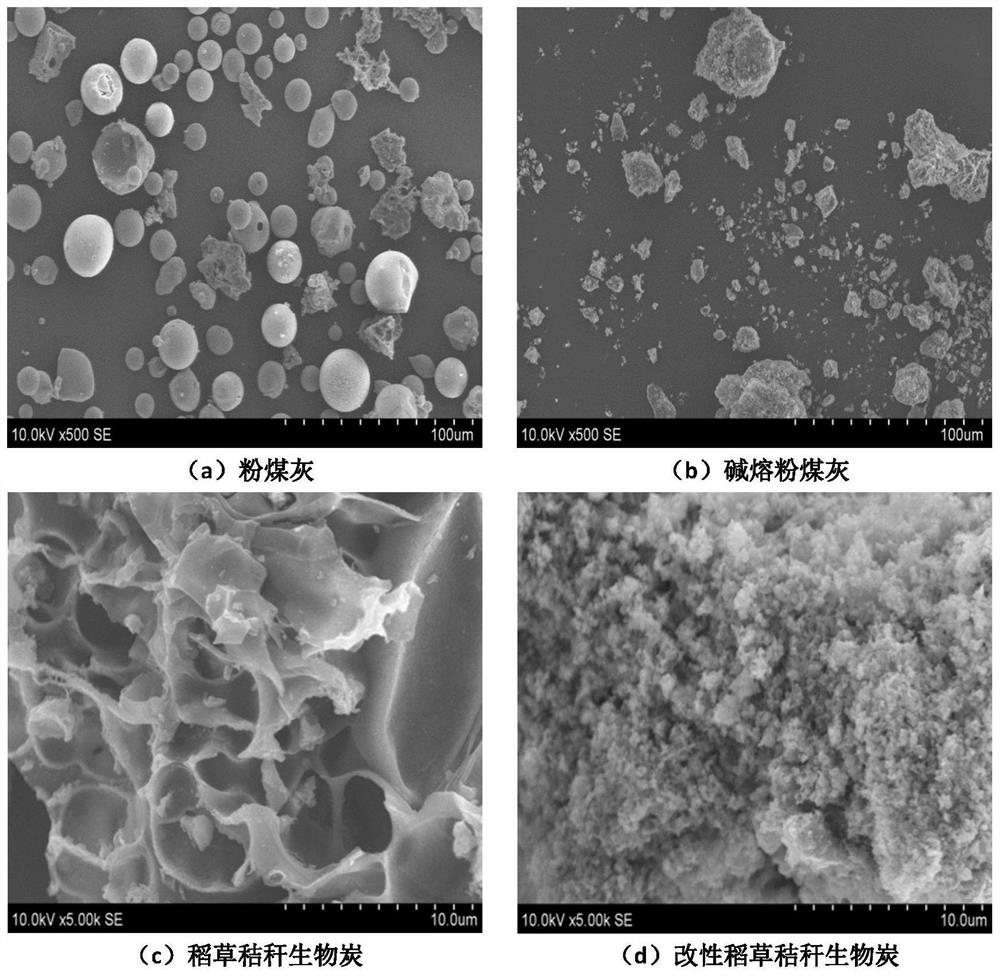

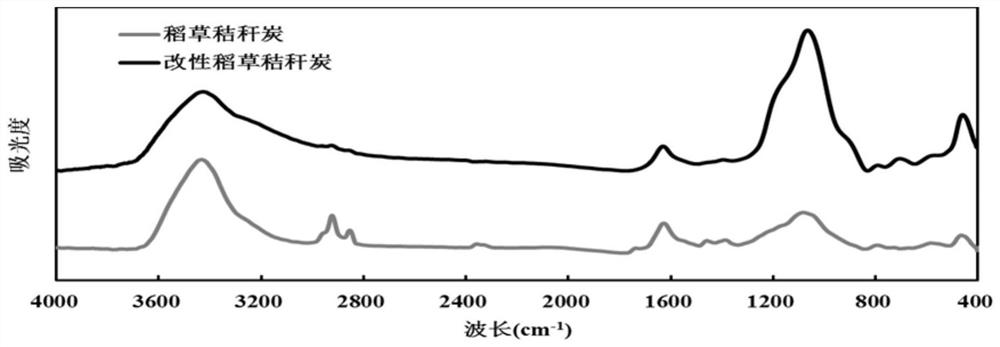

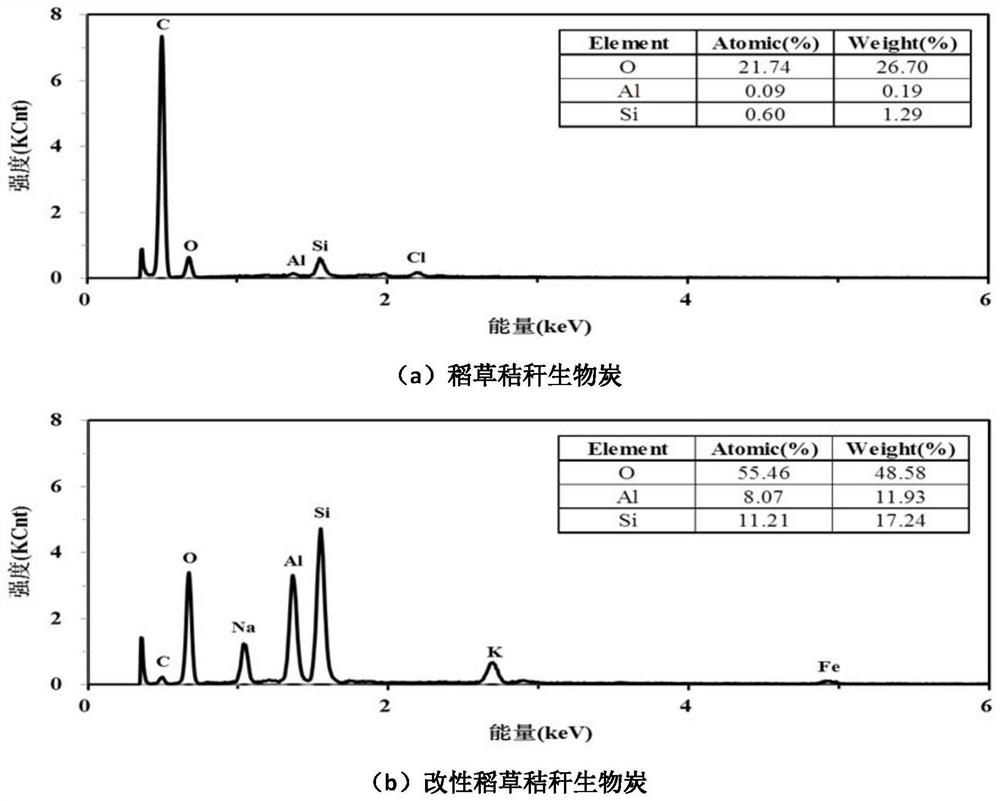

[0032] A kind of preparation method of modified rice straw biochar of the present invention, comprises the steps:

[0033] 1) Preparation of raw materials: collect coal-fired power plant fly ash and farmland rice straw with a particle size of less than 0.045mm, and dry the fly ash at 100-110°C; dry the rice straw at 70-90°C, and then Crush until the particle size is less than 1.00mm.

[0034] Among them, the chemical composition of coal-fired power plant fly ash is shown in Table 1.

[0035] Chemical composition (mass fraction) of table 1 fly ash Unit: %

[0036]

[0037]2) Preparation of alkali-melted fly ash: the fly ash and sodium hydroxide obtained in step 1) are mixed in a mass ratio of 1:1 to 1.5, and then roasted at a temperature of 600 to 700°C for 0.5 to 2 hours , The roasted product is crushed until the particle size is less than 1.00mm, and the fly ash after the alkali fusion treatment is obtained, that is, the alkali fusion fly ash. The sodium hydroxide is an...

Embodiment 1

[0042] Dry the fly ash collected in the power plant at 105°C, mix the dried fly ash and sodium hydroxide at a mass ratio of 1:1.2, put it into a corundum crucible, and use a muffle furnace at 650 After calcination at ℃ for 1 hour, take it out after cooling in the furnace, and after crushing, the particle size is less than 1.00mm to obtain alkali-melted fly ash. The farmland rice straw is dried at 80° C., and the particle size of the crushed rice straw is less than 1.00 mm. Mix the dried and pulverized rice straw and alkali-melted fly ash at a mass ratio of 10:3, that is, the added mass of alkali-melted fly ash is 30% of the mass of the rice straw, and then add deionized water into the mixture, The mass volume ratio of the mixture to deionized water is 1:10g / ml, shaken for 2 hours, dried at 80°C, and pulverized until the particle size is less than 1.00mm.

[0043] Put the dried rice straw and alkali-melted fly ash mixture in a corundum crucible, close the lid of the crucible, ...

Embodiment 2

[0046] Dry the fly ash collected in the power plant at 100°C, mix the dried fly ash and sodium hydroxide at a mass ratio of 1:1, put it into a corundum crucible, and use a muffle furnace at 600 After roasting at ℃ for 2 hours, take it out after cooling in the furnace, and after crushing, the particle size is less than 1.00mm to obtain alkali-melted fly ash. The farmland rice straw is dried at 70° C., and the particle size of the crushed rice straw is less than 1.00 mm. Mix the dried and pulverized rice straw and alkali-melted fly ash at a mass ratio of 10:1, that is, the added mass of alkali-melted fly ash is 10% of the mass of the rice straw, and then add a certain amount of Ionized water, the mass volume ratio of the mixture to deionized water is 1:10g / ml, shake for 4 hours, then dry at 70°C, and pulverize until the particle size is less than 1.00mm.

[0047] Put the dried rice straw and alkali-melted fly ash mixture in a corundum crucible, close the lid of the crucible, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com