Graphene-reinforced mining polyethylene composition, graphene-reinforced mining polyethylene particle, graphene-reinforced mining polyethylene pipe material, and preparation methods thereof

A graphene and polyethylene technology, applied in the field of polymer material technology and processing, can solve problems such as poor dispersibility, large addition amount, and melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

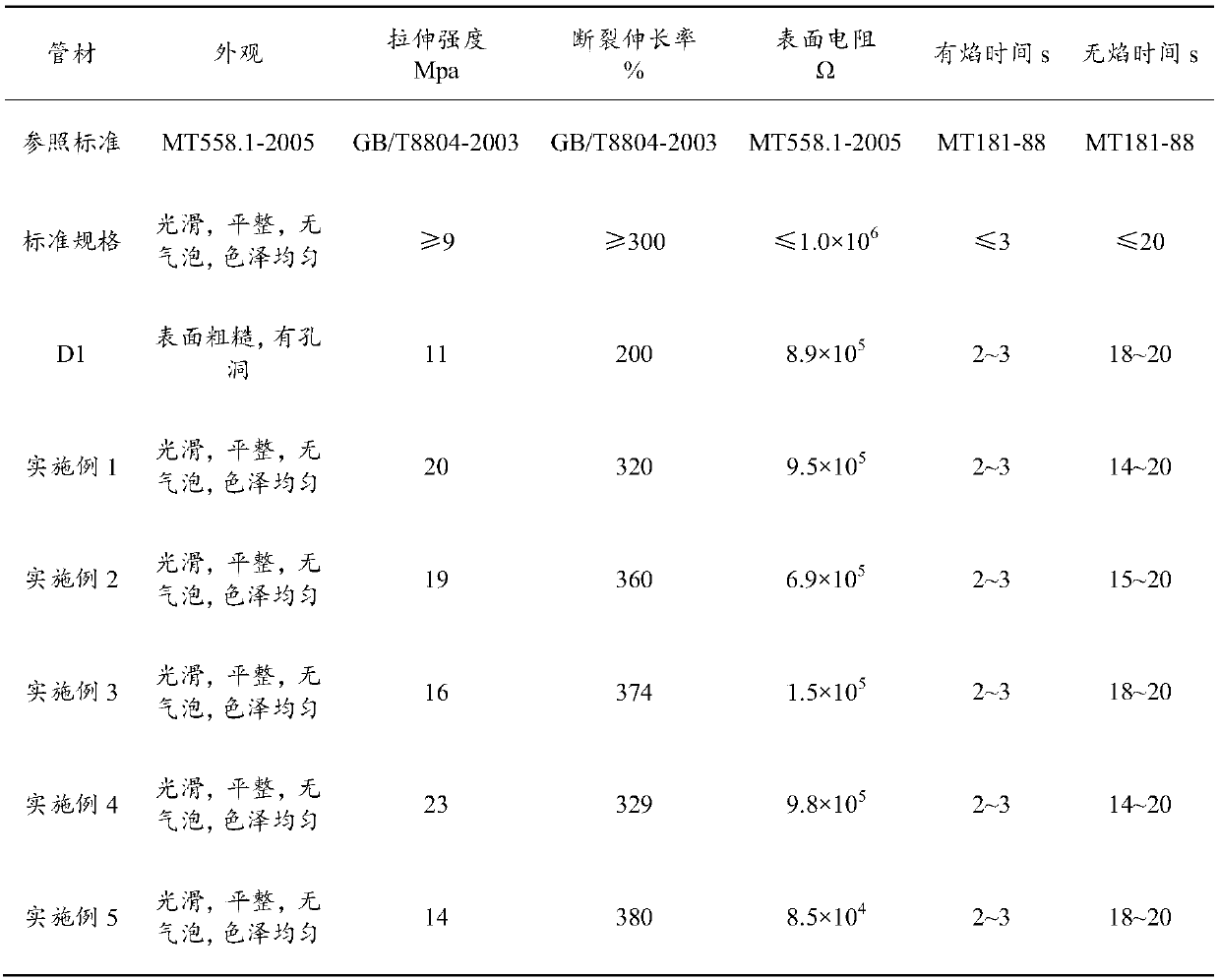

Examples

preparation example Construction

[0140] According to a preferred embodiment of the present invention, the preparation method of the dispersion includes: using white oil or synthetic oil as the dispersed phase, using PE wax, EBS (ethylene bis stearic acid amide), hyperdispersant A8021 or hyperdispersant One or the combination of two or more of the agent R1618 is used as the dispersion medium, and the dispersion liquid is prepared.

[0141] According to a preferred embodiment of the present invention, the nucleating agent is selected from one or a combination of two or more of calcium stearate, barium sulfate, silicate or titanium dioxide.

[0142] According to a preferred embodiment of the present invention, the toughening agent is selected from one or a combination of two or more of LLDPE, SEBS, SBS, POE, DOP or EVA.

[0143] According to a preferred embodiment of the present invention, the antioxidant is selected from one or a combination of two or more of antioxidant B215, antioxidant 1010, antioxidant 264,...

Embodiment 1

[0166] The present embodiment illustrates the preparation method of the graphene-enhanced mine polyethylene pipe of the present invention, comprising:

[0167] S1: Add 100 parts of high-density polyethylene, 3.0 parts of antioxidant B215, 18 parts of flame retardant red phosphorus, 8 parts of polypyrrole polymer, and 0.8 parts of PE wax white oil dispersion into the high-speed mixer in sequence , the mixing temperature is 25°C, the rotating speed is 700r / min; the mixing time is 35min; the obtained mixture and 1.5 parts of toughening agent EVA are added to the internal mixer for full melting and blending, and the rotating speed of the internal mixer is 40r / min, The temperature was controlled at 185°C, and the total mixing time was 12 minutes. The modified polyethylene particles were prepared by extruding and granulating through a double-wrist granulator. The extrusion speed of the granulator was 30r / min, and the extrusion temperature was controlled at 200°C.

[0168] S2: The m...

Embodiment 2

[0170] The present embodiment illustrates the preparation method of the graphene-enhanced mine polyethylene pipe of the present invention, comprising:

[0171] S1: Add 100 parts of high-density polyethylene, 2.5 parts of antioxidant B215, 15 parts of flame retardant red phosphorus, 18 parts of polyaniline polymer, and 1 part of A8021 white oil dispersion into the high-speed mixer in sequence, The mixing temperature is 30°C, the rotating speed is 650r / min; the mixing time is 25min; the obtained mixture and 3.5 parts of toughening agent SEBS are added to the internal mixer for full melt blending, the rotating speed of the internal mixer is 40r / min, the temperature The temperature is controlled at 230°C, and the total mixing time is 18 minutes. The modified polyethylene particles were prepared by extruding and granulating through a double-wrist granulator. The extrusion speed of the granulator was 28r / min, and the extrusion temperature was controlled at 240°C.

[0172] S2: The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com