Garbage environment-friendly regenerated coal high-efficiency energy-saving discharge-reducing additive and preparation and use method thereof

An additive preparation, high-efficiency and energy-saving technology, applied in the direction of biofuels, solid fuels, waste fuels, etc., can solve problems such as threats to residents' lives, water and soil resources pollution, and achieve the effects of saving resources, increasing combustion rates, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

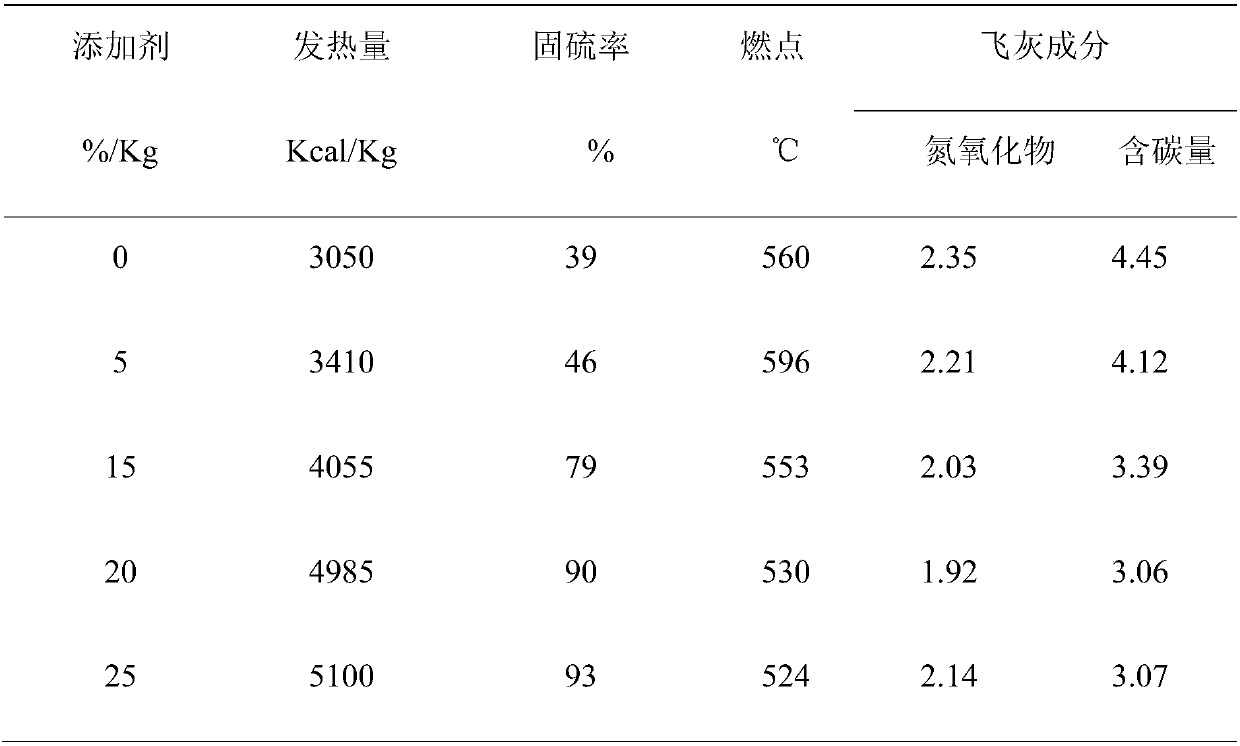

Image

Examples

Embodiment 1

[0031] A high-efficiency, energy-saving and emission-reducing additive for waste-environmental regenerated coal, the main components of which are in the following parts by weight: high-efficiency cleansing agent for regenerated coal: 10-20 parts; high-efficiency sub-fissile substance reactant for regenerated coal: 15-30 parts; High-efficiency flame-resistant synthetic agent for recycled coal: 50 to 75 parts.

[0032] Wherein, the components of the regenerated coal high-efficiency cleaning reaction agent are as follows in parts by weight: 10 to 20 parts of calcium oxide, 5 to 15 parts of sodium sulfate, 10 to 15 parts of lauryl amidopropyl amine oxide, polyethylene glycol 8-12 parts of glycol stearate, 3-5 parts of sodium citrate, 1-3 parts of citric acid, 3-5 parts of polyethylene glycol, 1-3 parts of ammonium sulfate, 0.1 parts of peppermint oil 0.3 parts to 0.3 parts, 0.1 to 0.3 parts of preservatives, 100 parts of deionized water. The components of the regenerated coal hig...

Embodiment 2

[0034] Experimental method: Weigh each component according to the following parts by weight: 10 to 20 parts of calcium oxide, 5 to 15 parts of sodium sulfate, 10 to 15 parts of lauryl amidopropylamine oxide, polyethylene glycol stearate 8 1 to 12 parts, 3 to 5 parts of sodium citrate, 1 to 3 parts of citric acid, 3 to 5 parts of polyethylene glycol, 1 to 3 parts of ammonium sulfate, 0.1 to 0.3 parts of peppermint oil, preservative 0.1 part to 0.3 part, 100 parts of deionized water; then prepare a high-efficiency cleaning reaction agent for recycled coal according to the following steps:

[0035] S1. First put deionized water into the reaction vessel and add calcium oxide to carry out chemical exothermic reaction. When the temperature rises to 35°C-40°C, add sodium sulfate, sodium citrate and polyethylene glycol and stir;

[0036] S2. Heat the solution in step S1, add ammonium sulfate, lauryl amidopropyl amine oxide and polyethylene glycol stearate at 50°C to 60°C and continue ...

Embodiment 3

[0040] Experiment method: Weigh each component according to the following parts by weight: 10-30 parts of sodium hypochlorite, 10-20 parts of potassium permanganate, 10-30 parts of hydrogen peroxide, 5-10 parts of zinc chloride, 5 parts of periodate 10 to 10 parts, 10 to 30 parts of sodium bismuthate, 5 to 15 parts of magnesium powder, 5 to 10 parts of zinc oxide or 10 to 40 parts of fluorite; then grind and pulverize each solid component separately, and then mix uniform, then add water to dissolve, and finally add various liquid components to obtain a high-efficiency sub-fissile substance reactant for regenerated coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com