Modular LED plant illuminating lamp

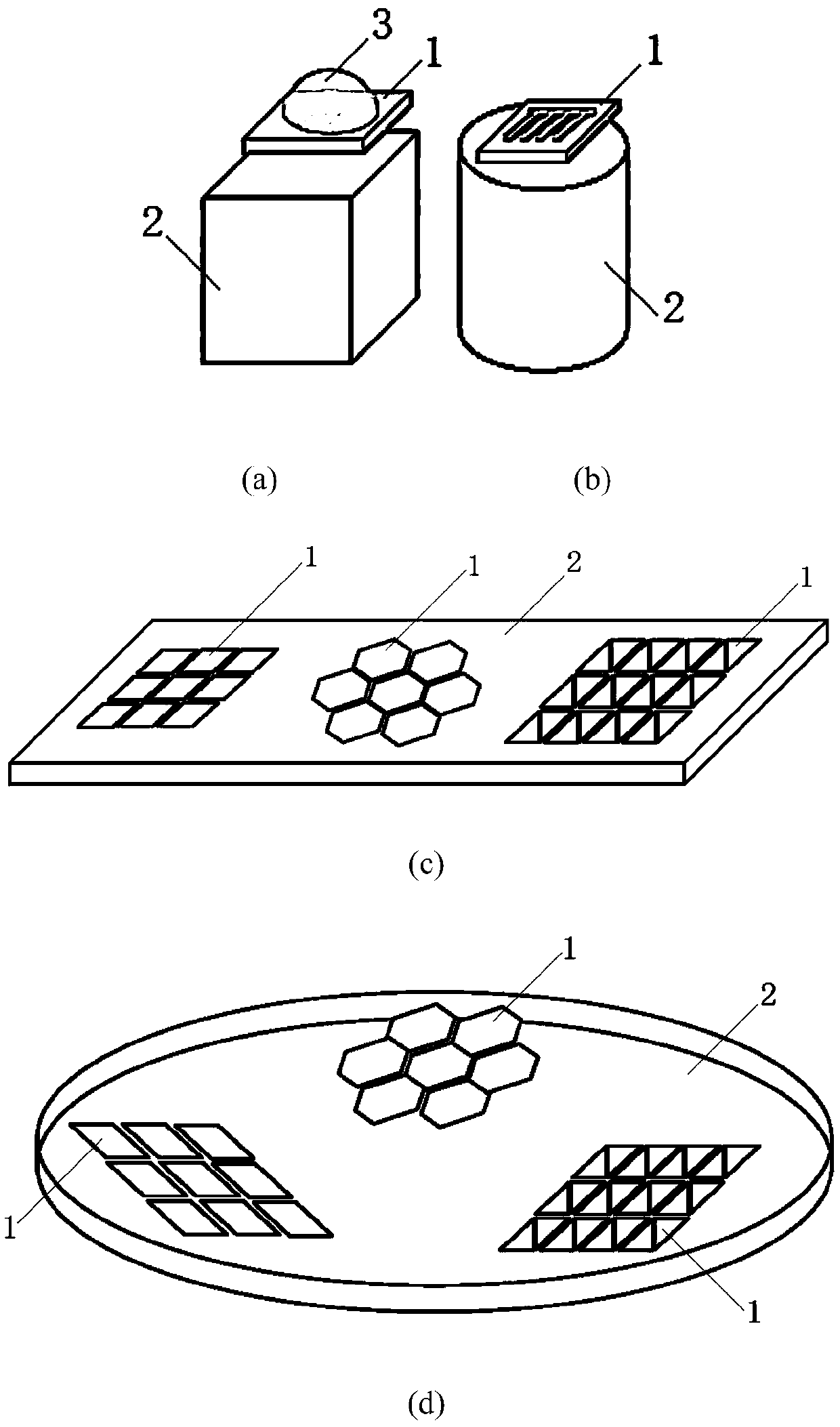

A technology for lighting lamps and LED light sources, applied in lighting devices, lighting and heating equipment, botanical equipment and methods, etc., can solve the problems of inability to flexibly adjust the light source, the waterproofness of lamps is deteriorated, and the inability to adjust flexibly, and to expand applications Field, increase the variety of changes, the effect of flexible adjustment of light angle and light field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

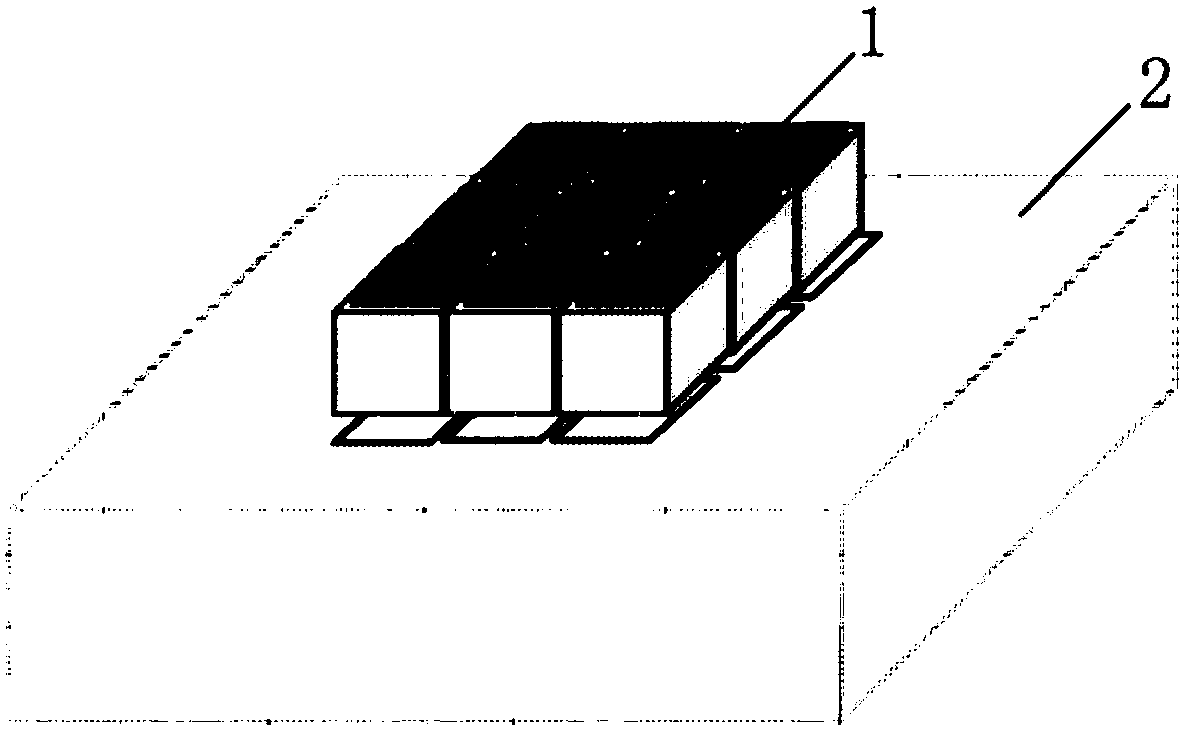

[0032] Embodiment 1: as image 3 As shown, a modular LED plant lighting provided by the present invention, its preparation method specifically includes the following steps:

[0033] (1) First, open holes on the primary heat sink, coat the surface with thermally conductive glue, fix red, blue, green and near-ultraviolet wavelength LED chips from 0.5W to 10W on it, and then use wires to lead from the LED chip The positive and negative leads are connected to the feet to complete the preparation of the LED light source module 1 with the primary heat sink; the heat sink is made of one or more of aluminum, aluminum alloy or copper, copper alloy, aluminum nitride, and heat-conducting ceramics. The glue is one or more combinations of silver glue and insulating glue, and the coating method of thermal conductive glue is one of spraying or dispensing;

[0034](2) Install the LED light source module 1 on the sealed lamp housing 2 with the corresponding installation position. The LED ligh...

Embodiment 2

[0037] Embodiment 2: as Figure 4 As shown, a modular LED plant lighting provided by the present invention, its preparation method specifically includes the following steps:

[0038] (1) Firstly, holes are made on the primary heat sink, and a heat conduction layer is prepared on the surface using thin film preparation technology, and red, blue, green and deep ultraviolet wavelength LED chips of 0.5W to 10W are fixed on it, and then Connect the positive and negative leads from the LED chip pins with wires to complete the preparation of the LED light source module 1 with the primary heat sink; the heat sink is made of one of aluminum, aluminum alloy or copper, copper alloy, aluminum nitride, and heat-conducting ceramic One or more, the thermal conductive material is one or more combinations of graphene and high thermal conductivity carbon-based films, and the film preparation technology is one or a combination of chemical or physical vapor deposition;

[0039] (2) The primary o...

Embodiment 3

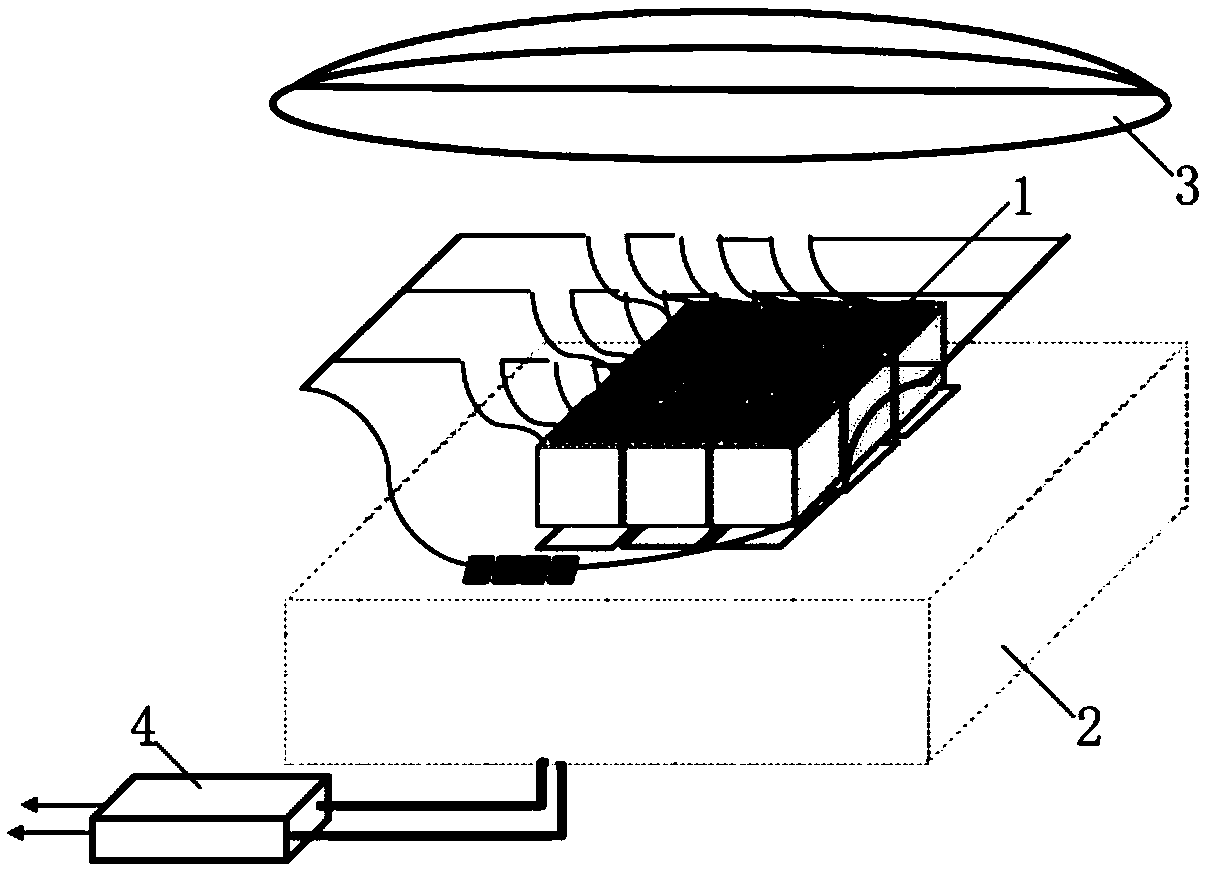

[0043] Embodiment 3: as Figure 5 As shown, a modular LED plant lighting provided by the present invention, its preparation method specifically includes the following steps:

[0044] (1) Firstly, holes are made on the primary heat sink, and a heat conduction layer is prepared on the surface using thin film preparation technology, and red, blue, green and deep ultraviolet wavelength LED chips of 0.5W to 10W are fixed on it, and then Use wires to connect the positive and negative leads from the LED chip pins to complete the preparation of the light source module with the primary heat sink; the heat sink is made of one of aluminum, aluminum alloy or copper, copper alloy, aluminum nitride, heat-conducting ceramics or Various, the thermal conductive material is one or more combinations of graphene and high thermal conductivity carbon-based film, and the film preparation technology is one or a combination of chemical or physical vapor deposition;

[0045] (2) The primary optical le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com