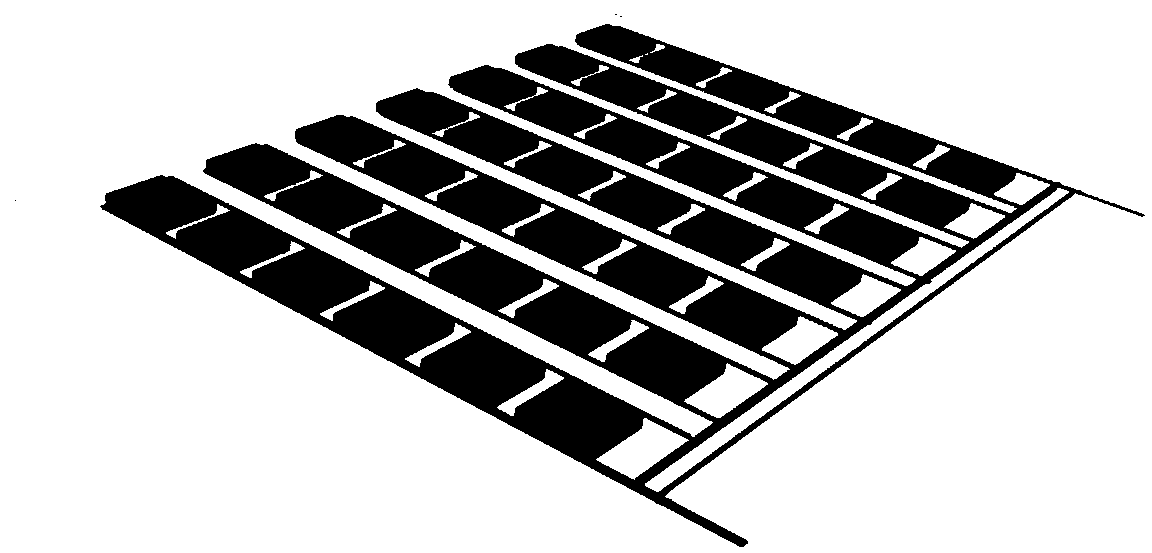

Flexible and foldable all-solid-state battery and manufacturing method thereof

An all-solid-state battery and all-solid-state technology, which is applied in the direction of sustainable manufacturing/processing, secondary batteries, solid electrolytes, etc., can solve the problems of incapable of large-scale manufacturing, brittleness, and high hardness of solid-state batteries, and achieve high safety and expansion Application Range, Effect of High Energy Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

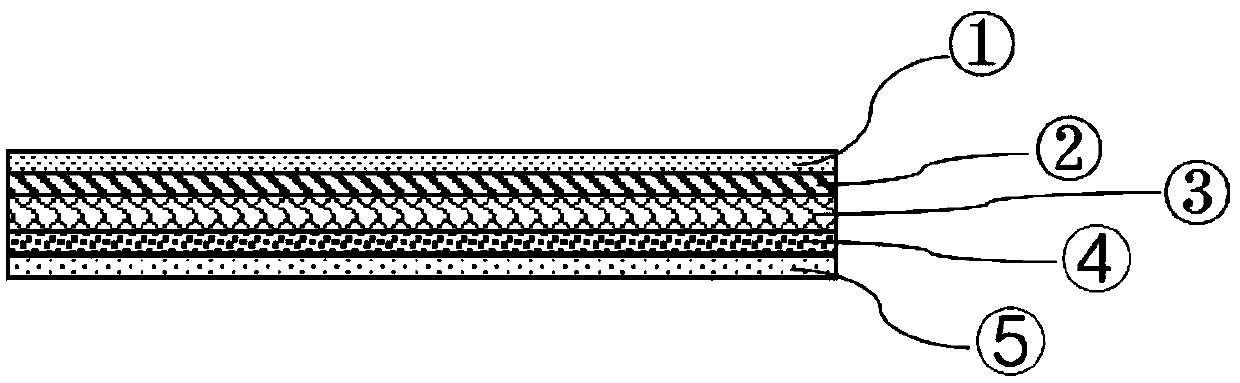

[0038] A method for manufacturing a flexible and foldable all-solid-state battery, the method comprising the following steps:

[0039] S1, preparation of positive and negative electrode material mixture

[0040] In a glove box filled with argon, weigh 5 mg of the cathode material mixture, 30 mg of Li 6 P.S. 5 Cl solid electrolyte and 5mg negative electrode material mixture, spare;

[0041] Lithium iron phosphate powder, Li 6 P.S. 5 Cl and acetylene black are mixed uniformly by mass ratio 1:1:(1 / 2) to obtain positive electrode material mixture;

[0042] Graphite powder and Li 6 P.S. 5 Cl was mixed uniformly at a mass ratio of 1:1 to obtain a negative electrode material mixture.

[0043] S2. Manufacture of miniature all-solid-state batteries

[0044] According to aluminum foil, cathode material mixture, Li 6 P.S. 5 The sequence of Cl solid electrolyte, negative electrode material mixture, and copper foil was uniformly put into a square mold of 8 mm × 8 mm in sequence, ...

Embodiment 2

[0049] A method for manufacturing a flexible and foldable all-solid-state battery, the method comprising the following steps:

[0050] S1, preparation of positive and negative electrode material mixture

[0051] In a glove box filled with argon, weigh 10 mg of cathode material mixture, 20 mg of Li 6 P.S. 5 Br solid electrolyte and 10mg negative electrode material mixture, spare;

[0052] Lithium cobalt oxide powder, Li 6 P.S. 5Br and carbon nanotubes are uniformly mixed in a mass ratio of 1:(3 / 5):(2 / 5) to obtain a positive electrode material mixture;

[0053] Graphite powder and Li 6 P.S. 5 Br was uniformly mixed at a mass ratio of 1:(2 / 3) to obtain a negative electrode material mixture.

[0054] S2. Manufacture of miniature all-solid-state batteries

[0055] According to aluminum foil, cathode material mixture, Li 6 P.S. 5 The sequence of Br solid electrolyte, negative electrode material mixture, and copper foil was uniformly put into a 6mm×6mm square mold in turn, ...

Embodiment 3

[0060] A method for manufacturing a flexible and foldable all-solid-state battery, the method comprising the following steps:

[0061] S1, preparation of positive and negative electrode material mixture

[0062] In a glove box filled with argon, weigh 5 mg of the cathode material mixture, 30 mg of Li 6 PS- 5 Br solid electrolyte and 5mg negative electrode material mixture, spare;

[0063] Lithium manganese oxide powder, Li 3 P.S. 4 Mix with acetylene black in mass ratio 1:(1 / 3):(1 / 3) to obtain positive electrode material mixture;

[0064] Graphite powder and Li 3 P.S. 4 According to the mass ratio of 1:(1 / 2), mix uniformly to obtain the negative electrode material mixture.

[0065] S2. Manufacture of miniature all-solid-state batteries

[0066] According to aluminum foil, cathode material mixture, Li 3 P.S. 4 The sequence of solid electrolyte, negative electrode material mixture, and copper foil was evenly put into a 13mm×15mm square mold in turn, kept under 300MPa p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com