Method for jointly treating dried bean curd based on combination of ultrasonic waves and gas jet impact drying

A gas jet and combined treatment technology, which is applied in food ultrasonic treatment, cheese substitutes, dairy products, etc., can solve the problems of low hot air drying efficiency, long time consumption, and easy contamination of products, so as to increase the speed of movement and penetration ability, reduce drying time and temperature, and improve the effect of salt penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is based on the method of combined treatment of dried bean curd by ultrasonic wave and gas jet impact drying method, and its process steps are:

[0037] (1) Pre-processing

[0038] The soybean raw material is sequentially soaked, cleaned, refined, boiled, pulped, and pressed, and then cut into tofu blocks with a size of 3.5cm×3.5cm×2cm;

[0039] (2) Ultrasonic halogenation

[0040] Put the cut bean curd pieces in step (1) into a saline solution with a mass concentration of 8%, and conduct ultrasonic treatment for 30 minutes at a temperature of 70°C, an ultrasonic sound energy density of 0.77W / ml, and an ultrasonic frequency of 25KHZ;

[0041] (3) Gas jet impact drying

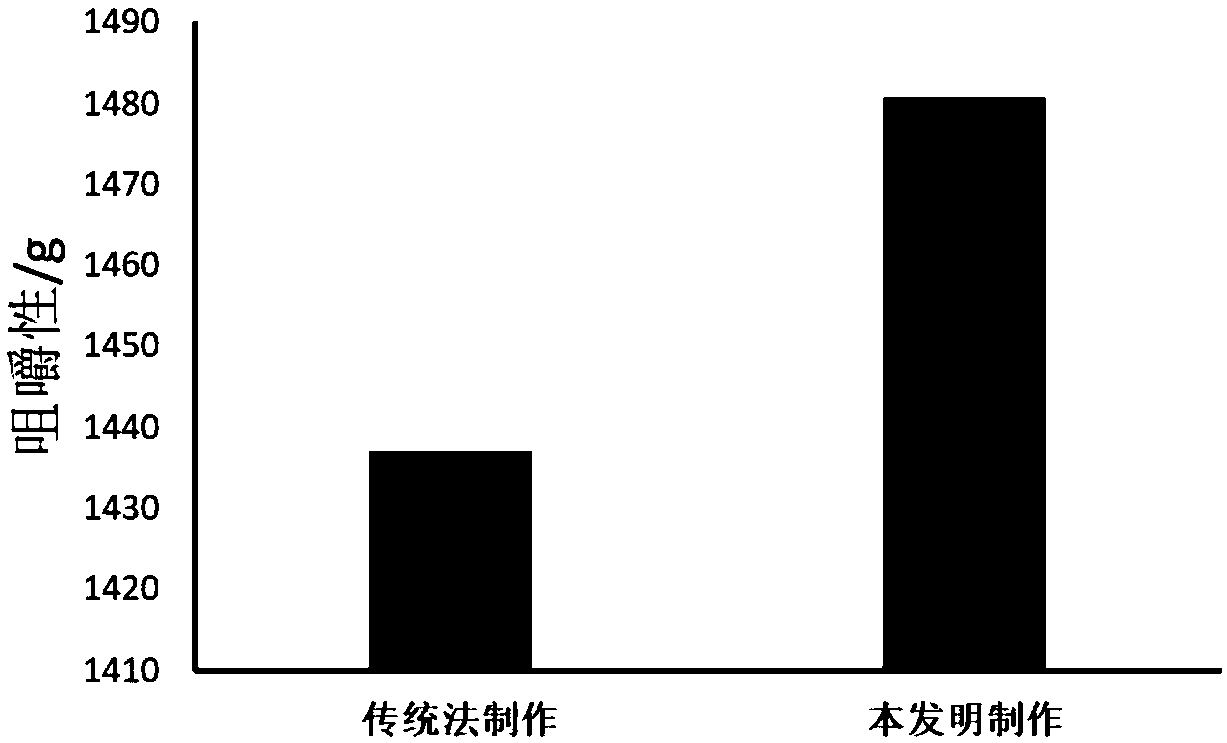

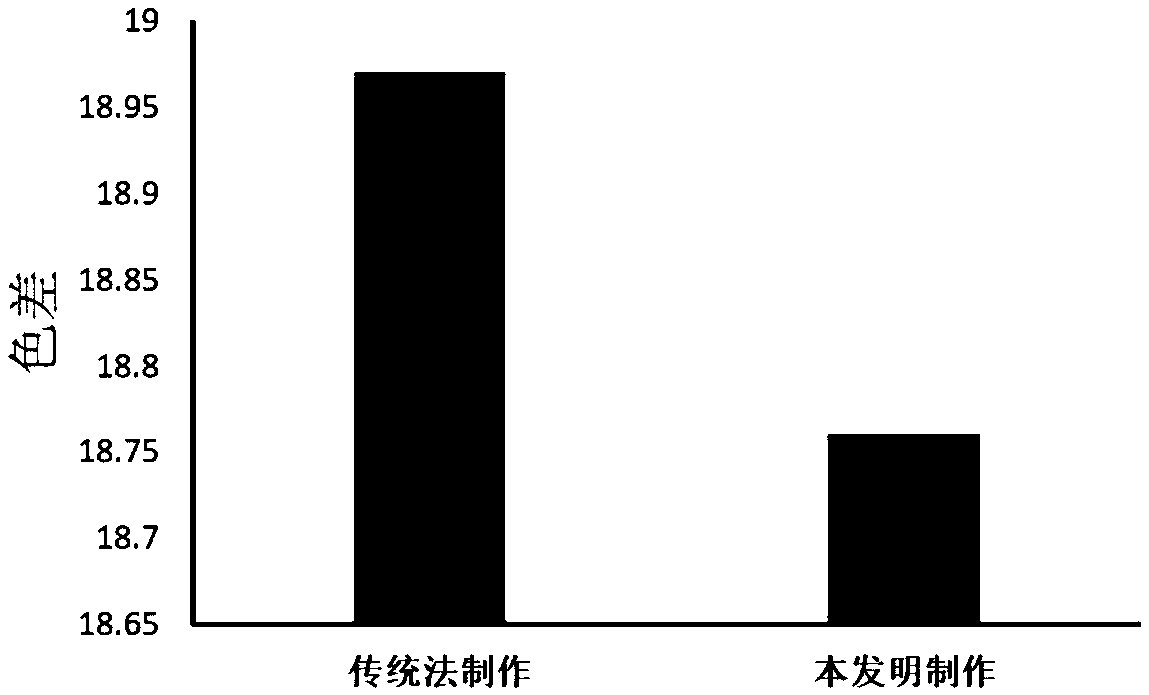

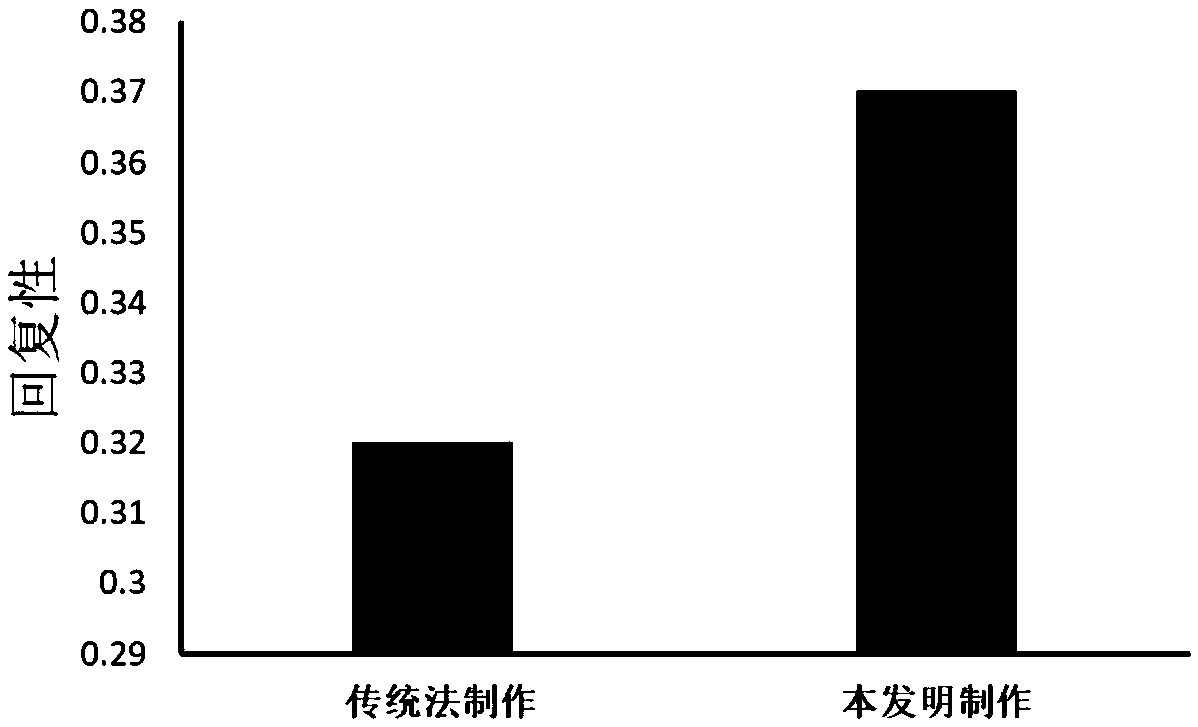

[0042] Lay the bean curd block prepared through step (2) on the mesh screen of the impact air dryer, and dry it for 180 min at a wind temperature of 72°C and an air velocity of 9.0m / s until the water content is 56%. The effects of ultrasonic extrusion, expansion and thinning of the dif...

Embodiment 2

[0048] This embodiment is based on the method of combined treatment of dried bean curd by ultrasonic wave and gas jet impact drying method, and its process steps are:

[0049] (1) Pre-processing

[0050] The soybean raw material is sequentially soaked, cleaned, refined, boiled, pulped, and pressed, and then cut into tofu blocks with a size of 3cm×3cm×2cm;

[0051] (2) Ultrasonic halogenation

[0052] Put the cut tofu pieces in step (1) into a saline solution with a mass concentration of 3%, at a temperature of 50°C, an ultrasonic sound energy density of 1.23W / ml, and an ultrasonic frequency of 15KHZ for 40 minutes, and use ultrasonic The effects of extrusion, expansion and thinning of the diffusion boundary layer can improve the speed of salt infiltration and marinating of dried tofu;

[0053] (3) Gas jet impact drying

[0054]Lay the bean curd cubes marinated in step (2) on the mesh screen of the impingement air dryer, dry for 140min at a wind temperature of 60°C and an ai...

Embodiment 3

[0060] This embodiment is based on the method of combined treatment of dried bean curd by ultrasonic wave and gas jet impact drying method, and its process steps are:

[0061] (1) Pre-processing

[0062] The soybean raw material is sequentially soaked, cleaned, refined, boiled, pulped, and pressed, and then cut into tofu blocks with a size of 4cm×4cm×2cm;

[0063] (2) Ultrasonic halogenation

[0064] Put the cut tofu pieces in step (1) into a saline solution with a mass concentration of 5%, at a temperature of 80°C, an ultrasonic sound energy density of 1.10W / ml, and an ultrasonic frequency of 30KHZ for 20 minutes, and use ultrasonic The effects of extrusion, expansion and thinning of the diffusion boundary layer can improve the speed of salt infiltration and marinating of dried tofu;

[0065] (3) Gas jet impact drying

[0066] Lay the bean curd cubes marinated in step (2) on the mesh screen of the impingement air dryer, dry for 200 min at a wind temperature of 80° C. and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com