Pd/C catalyst and preparation method thereof

A technology of catalyst and reducing agent, which is applied in the field of Pd/C catalyst and its preparation, can solve the problems of serious influence on electrochemical catalysis, unfavorable mass production of Pd catalyst, reduction of catalytic activity and catalytic selectivity of catalyst, and achieve high catalytic activity As well as anti-attenuation performance, excellent electrocatalytic activity, and the effect of realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

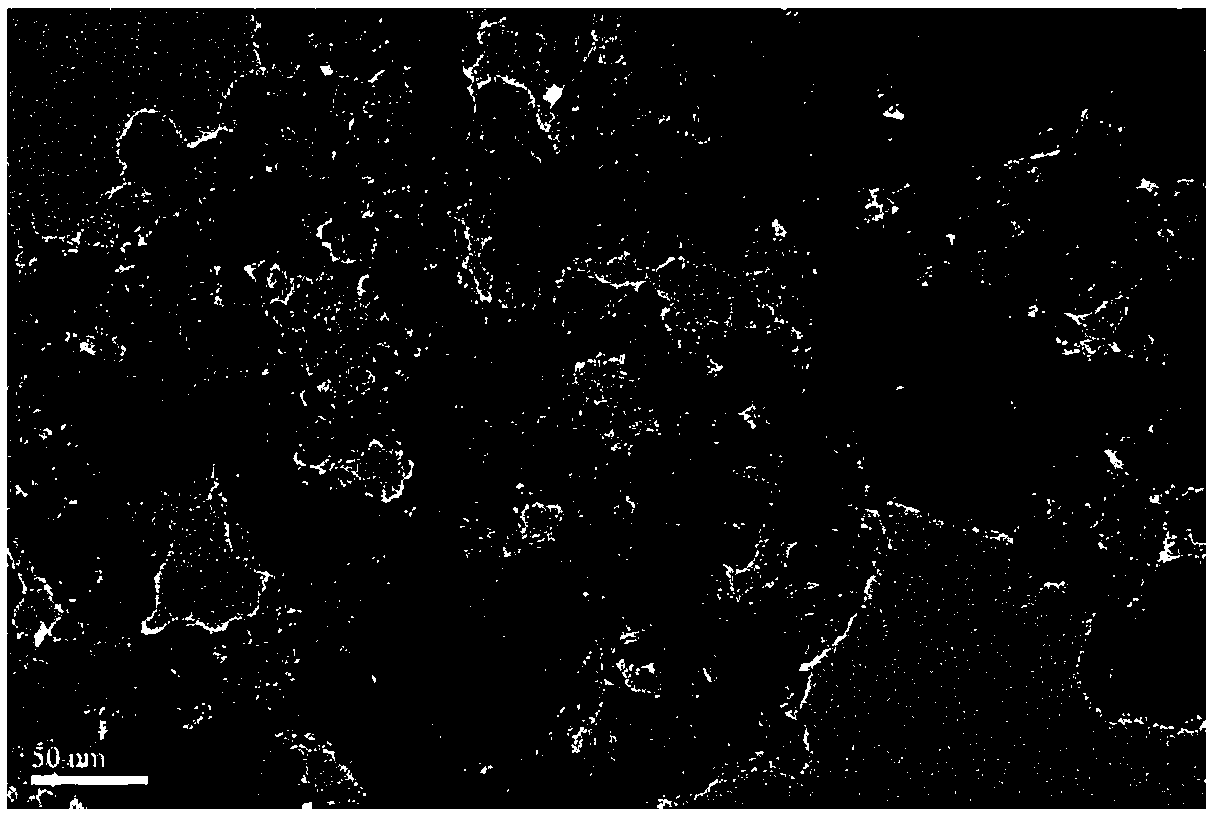

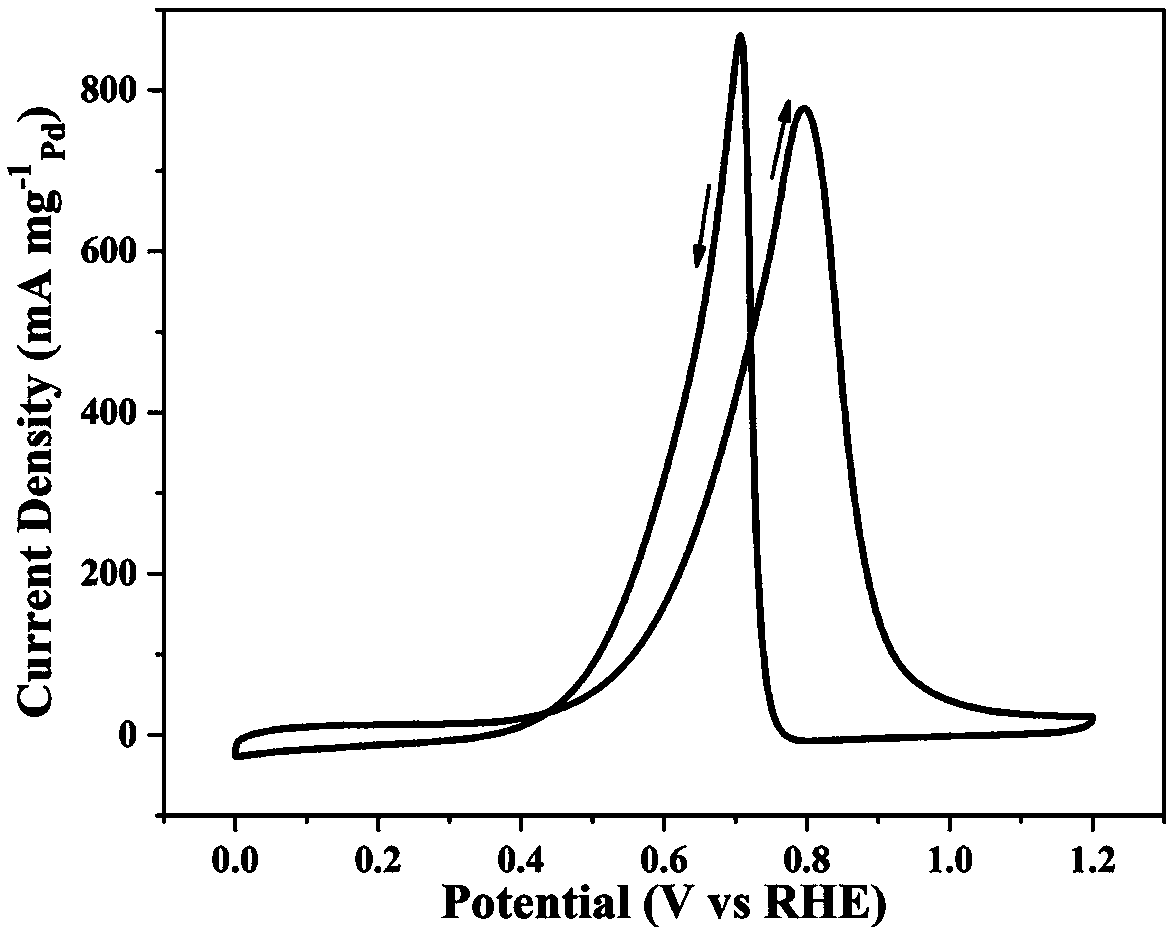

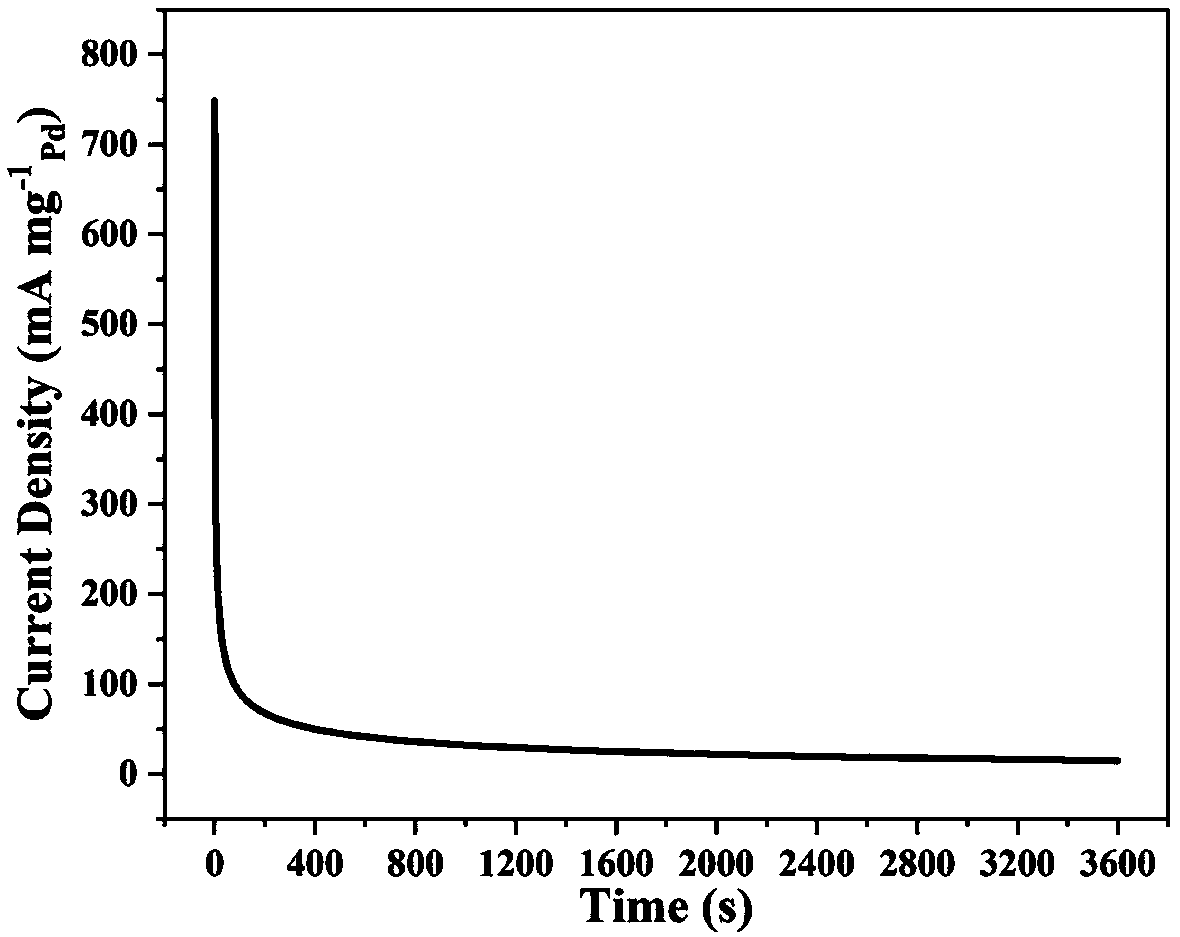

Image

Examples

Embodiment example 1

[0032] 1. Weigh 0.1185mmol PdCl 2 In the flask, add HCl to make 0.1M H 2 PdCl 4 solution, then add 5ml of water, after stirring evenly, add 400ul ammonia water, stir magnetically until the solution becomes colorless and transparent; the molar volume concentration of Pd in the solution is 1.8×10 -2 mol / L, the molar ratio of Pd to ammonia water is 1:22;

[0033] 2. Add 30ml of ultrapure water to the flask, then add 1.5ml of 1M NaOH solution, and stir magnetically for 20min;

[0034] 3. Add 37.5 mg of carbon black powder to the flask, ultrasonicate at 100W for 30 minutes, then transfer the flask to an oil bath, and stir magnetically for 2 hours under an Ar gas atmosphere;

[0035] 4. Then, under the condition of magnetic stirring, add 1ml formaldehyde solution into the flask, and stir for 10min; the molar ratio of Pd to formaldehyde is 1:115.5;

[0036] 5. Heat the above mixture to 60°C at a heating rate of 2°C / min, and react at this temperature for 2 hours;

[0037] 6. Su...

Embodiment example 2

[0039] 1. Weigh 0.1185mmol Na 2 PdCl 4 In the flask, add ultrapure water to make 0.1M Na 2 PdCl 4 solution, then add 5ml of water, after stirring evenly, add 400ul ammonia water, and magnetically stir until the solution becomes colorless and transparent; the molar volume concentration of Pd in the solution is 1.8×10 -2 mol / L, the molar ratio of Pd to ammonia water is 1:22;

[0040] 2. Add 30ml of ultrapure water to the flask, then add 1.5ml of 1M NaOH solution, and stir magnetically for 20min;

[0041] 3. Add 37.5 mg of carbon black powder to the flask, ultrasonicate at 100W for 30 minutes, then transfer the flask to an oil bath, and stir magnetically for 2 hours under an Ar gas atmosphere;

[0042] 4. Then, under the condition of magnetic stirring, add 1ml formaldehyde solution into the flask, and stir for 10min; the molar ratio of Pd to formaldehyde is 1:115.5;

[0043] 5. Heat the above mixture to 60°C at a heating rate of 2°C / min, and react at this temperature for 2...

Embodiment example 3

[0046] 1. Weigh 0.1185mmol K 2 PdCl 4 In the flask, add ultrapure water to make 0.1M K 2 PdCl 4 solution, then add 5ml of water, after stirring evenly, add 400ul ammonia water, and magnetically stir until the solution becomes colorless and transparent; the molar volume concentration of Pd in the solution is 1.8×10 -2 mol / L, the molar ratio of Pd to ammonia water is 1:22;

[0047] 2. Add 30ml of ultrapure water to the flask, then add 1.5ml of 1M NaOH solution, and stir magnetically for 20min;

[0048] 3. Add 37.5 mg of carbon black powder to the flask, ultrasonicate at 100W for 30 minutes, then transfer the flask to an oil bath, and stir magnetically for 2 hours under an Ar gas atmosphere;

[0049] 4. Then, under the condition of magnetic stirring, add 1ml formaldehyde solution into the flask, and stir for 10min; the molar ratio of Pd to formaldehyde is 1:115.5;

[0050] 5. Heat the above mixture to 60°C at a heating rate of 2°C / min, and react at this temperature for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com