Preparation and application of biomass-based porous carbon material based on platanus orientalis seeds

A technology of three-ball sycamore and porous carbon material, applied in the field of materials, can solve the problems such as the related reports of biomass-based porous carbon materials, increase the risk of polluting the environment, increase the amount of strong alkali, etc., and achieve high specific capacitance. The effect of small usage and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) separating the syringa syringae seeds from the syringa syringae fruit, cleaning and drying with ethanol and water; then pulverizing it and sieving through an 80-mesh sieve to obtain dry syringa syringae seed powder;

[0028] (2) Take 3g of dried Platanus tribulus seed powder, 2.7g of potassium hydroxide and 30g of deionized water into a 50mL polytetrafluoroethylene liner, hydrothermally treat it in a high-pressure hydrothermal reactor at 150°C for 5h, and then cool to room temperature. Subsequently, the hydrothermal product is dried to obtain pretreated Platanus tribulb seed powder containing potassium hydroxide;

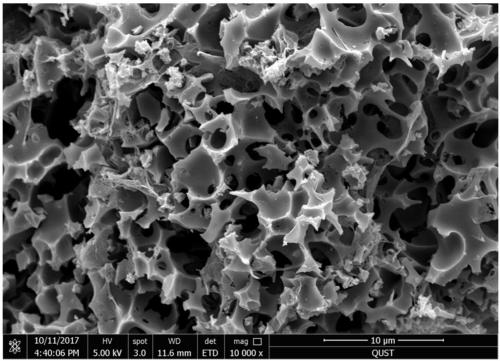

[0029] (3) Put the Platanus tribulus seed powder obtained in step (2) in a tube furnace, and under the protection of nitrogen, heat up to 700°C at a heating rate of 5°C / min and pyrolyze at this temperature for 4h, then Naturally cool to room temperature. The carbonized material was refluxed with 4 mol / L acetic acid solution at 60 °C for 3 h; then washed...

Embodiment 2

[0033](1) separating the sycamore seeds from the sycamore fruit, cleaning and drying with ethanol and water, then pulverizing them, and sieving through a 100-mesh sieve to obtain dry syringa seeds powder;

[0034] (2) Take 3g of dried Platanus tribulus seed powder, 2.7g of potassium hydroxide and 30g of deionized water into a 50mL polytetrafluoroethylene lining, hydrothermally treat in a high-pressure hydrothermal reactor at 160°C for 3h, and then cool to room temperature; then the hydrothermal product is dried to obtain the pretreated Platanus tribulus seed powder containing potassium hydroxide;

[0035] (3) Place the Platanus tribulus seed powder obtained in step (2) in a tube furnace, and under the protection of nitrogen, heat up to 800°C at a heating rate of 5°C / min and pyrolyze at this temperature for 2h, then Naturally cool to room temperature. The carbonized material was refluxed with 4 mol / L hydrochloric acid solution at 60 °C for 3 h, then washed with deionized water...

Embodiment 3

[0040] (1) separating the sycamore seeds from the sycamore fruit, cleaning and drying with ethanol and water, then pulverizing them, and sieving through a 100-mesh sieve to obtain dry syringa seeds powder;

[0041] (2) Take 3g of dried Platanus tribulus seed powder, 2.7g of potassium hydroxide and 30g of deionized water into a 50mL polytetrafluoroethylene lining, and hydrothermally treat it in a high-pressure hydrothermal reactor at 140°C for 7h; then cool to room temperature, followed by drying the hydrothermal product to obtain the pretreated Platanus tribulus seed powder containing potassium hydroxide;

[0042] (3) Put the sycamore seed powder obtained in step (2) in a tube furnace, and under the protection of nitrogen, heat up to 900°C for 2 hours at a rate of 5°C / min for pyrolysis, and then cool naturally to room temperature. The carbonized material was refluxed with 4mol / L sulfuric acid solution at 60°C for 3h, then washed with deionized water to neutrality, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com