Preparation of bifeo based on hydrothermal method 3 Nanosheet method and bifeo 3 Nanosheets

A technology of nanosheets and hydrothermal method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve problems such as high temperature requirements, small synthetic particle size, and difficult mixing to achieve dispersibility Good, good crystallization, excellent feasibility and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 0.699g (3mmol / L) of bismuth oxide with 4mL of 37% hydrochloric acid, add 46mL of water, then add 0.812g (6mmol / L) of ferric chloride hexahydrate, and stir until dissolved.

[0026] (2) Add 2.675g (1mol / L) of ammonium chloride to the above solution, and add 12g (6mol / L) of sodium hydroxide after dissolving. Seal with plastic wrap and stir with a magnetic stirrer for 20 minutes to form BiFeO 3 Precursor.

[0027] (3) Put the above precursor into a polytetrafluoroethylene hydrothermal kettle, and heat it at 200°C for 10 hours. After the reaction, cool to room temperature. Lotion, dry to get BiFeO 3 Nanosheets.

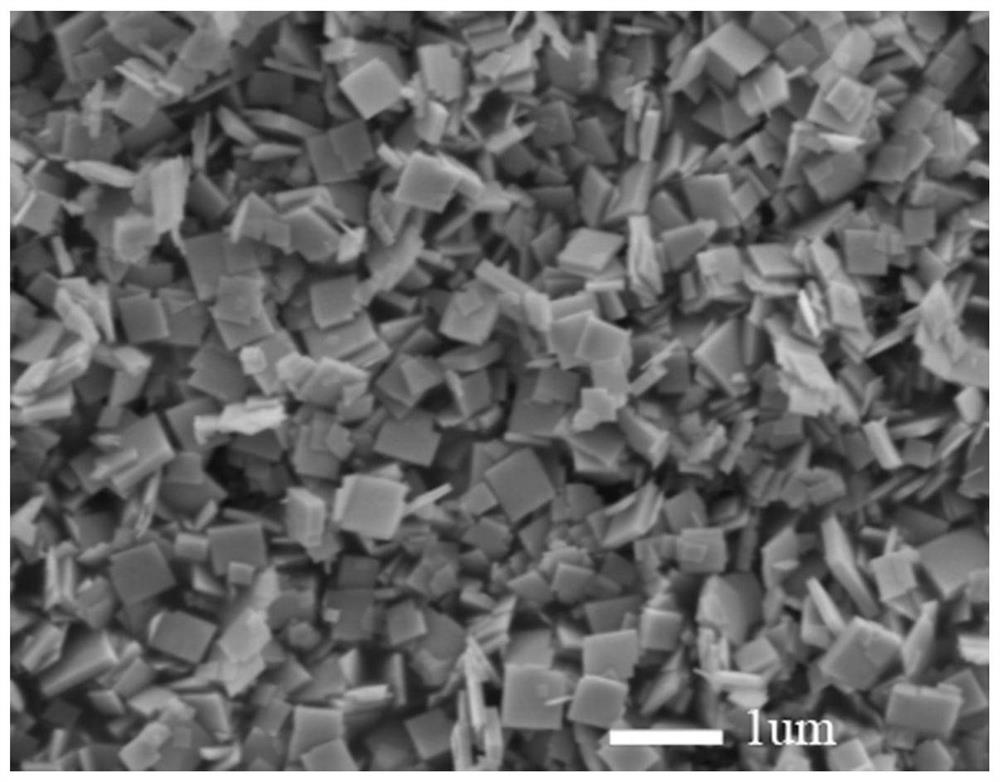

[0028] figure 1 In this embodiment, the mineralizer is 6 mol / L, and the hydrothermal time is the SEM image of 10 h. It can be seen that the morphology is basically flakes, the dispersion is good, the size is 300-500nm, and the thickness is 50nm.

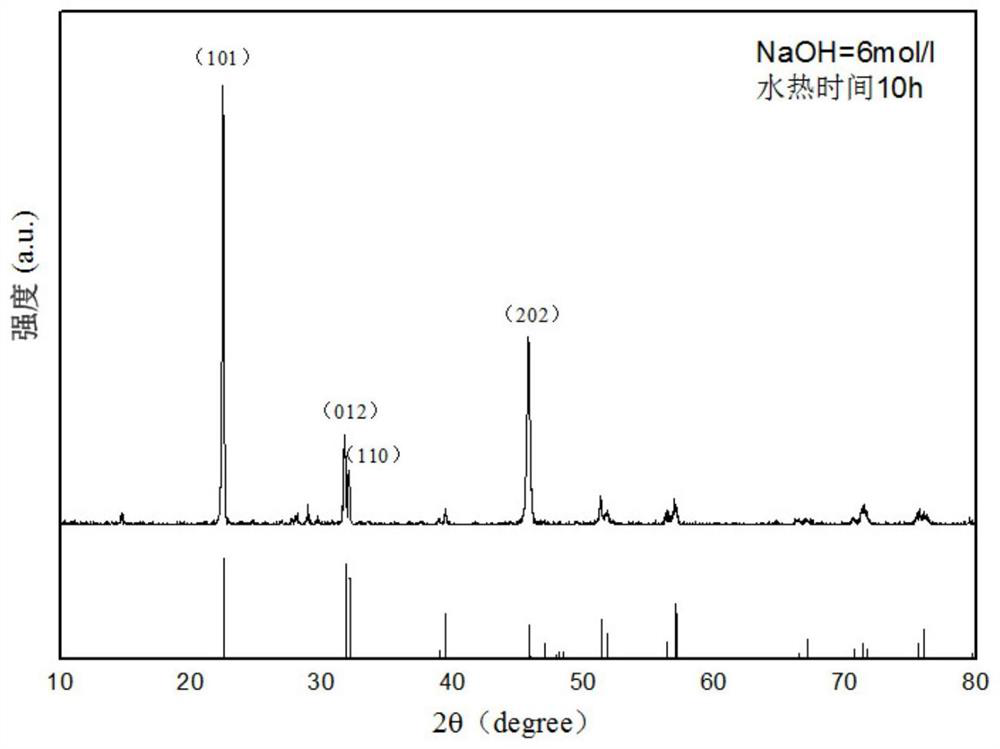

[0029] figure 2 In this embodiment, the mineralizer is 6mol / L, and the hydrothermal time is the X...

Embodiment 2

[0031] (1) Dissolve 0.699g (3mmol / L) of bismuth oxide in 4mL of 37% hydrochloric acid, add 46mL of water, then add 0.812g (6mmol / L) of ferric chloride hexahydrate, and stir until dissolved.

[0032] (2) Add 2.675g (1mol / L) of ammonium chloride to the above solution, and add 16g (8mol / L) of sodium hydroxide after dissolving. Seal with plastic wrap and stir with a magnetic stirrer for 20 minutes to form BiFeO 3 Precursor.

[0033] (3) Put the above precursor into a polytetrafluoroethylene hydrothermal kettle, and heat it at 200°C for 10 hours. After the reaction, cool to room temperature. Lotion, dry to get BiFeO 3 Nanosheets.

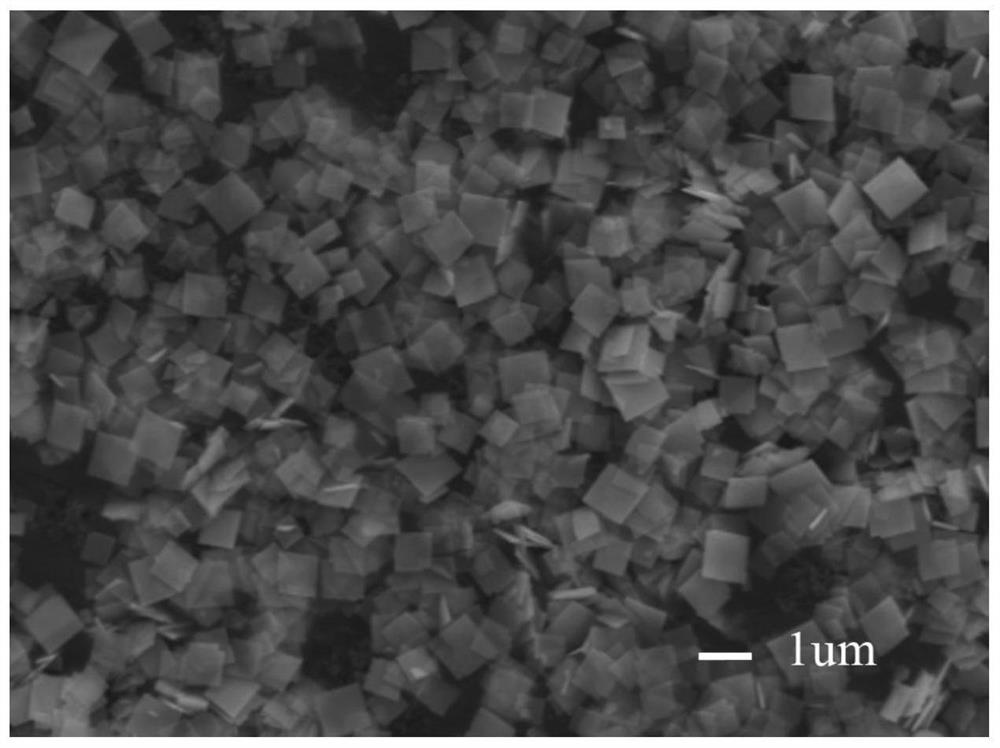

[0034] image 3 In this embodiment, the mineralizer is 8mol / L, and the hydrothermal time is the SEM image of 10h. It can be seen that the morphology is basically flakes, the dispersion is good, the size is 600-800nm, and the thickness is 50nm.

[0035] Figure 4 In the present embodiment, the mineralizer is 8mol / L, and the hydrothermal time is th...

Embodiment 3

[0037] (1) Dissolve 0.699g (3mmol / L) of bismuth oxide in 4mL of 37% hydrochloric acid, add 46mL of water, then add 0.812g (6mmol / L) of ferric chloride hexahydrate, and stir until dissolved.

[0038] (2) Add 2.675g (1mol / L) ammonium chloride to the above solution, and add an appropriate amount of 12g (6mol / L) sodium hydroxide after dissolving. Seal with plastic wrap and stir with a magnetic stirrer for 20 minutes to form BiFeO 3 Precursor.

[0039] (3) Put the above precursor into a polytetrafluoroethylene hydrothermal kettle, and heat it at 200°C for 10 hours. After the reaction, cool to room temperature. Lotion, dry to get BiFeO 3 Nanosheets.

[0040] Figure 5 In this embodiment, the mineralizer is 6 mol / L, and the hydrothermal time is the SEM image of 6 hours. It can be seen that the morphology is basically flakes, with good dispersion, and the size is between 500-700nm, but the thickness of the flakes varies greatly and is distributed in 50-200nm.

[0041] Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com