Method for degrading acid orange 7 through ferro-manganese bimetallic catalyst containing carbon

A bimetallic catalyst and acid orange technology, applied in the field of water pollution control, can solve the problems of difficult recovery, limited pH application range, and low utilization efficiency of catalysts and oxidants, and achieves high utilization efficiency, wide application range, and avoidance of secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

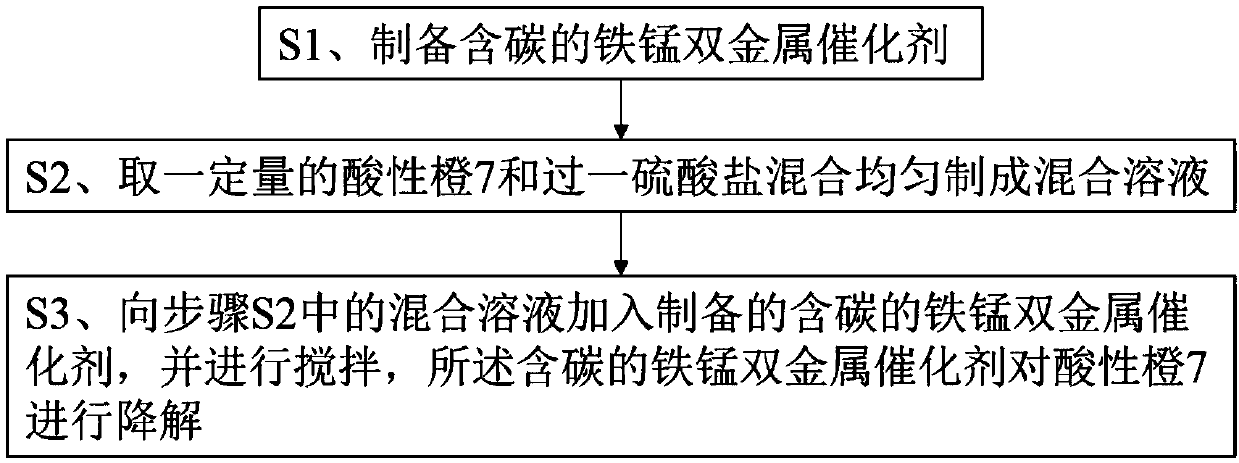

[0032] refer to figure 1 with figure 2 , the embodiment of the present invention provides a method for degrading Acid Orange 7 with a carbon-containing iron-manganese bimetallic catalyst, and the specific steps are as follows:

[0033] S1, prepare carbon-containing iron-manganese bimetallic catalyst;

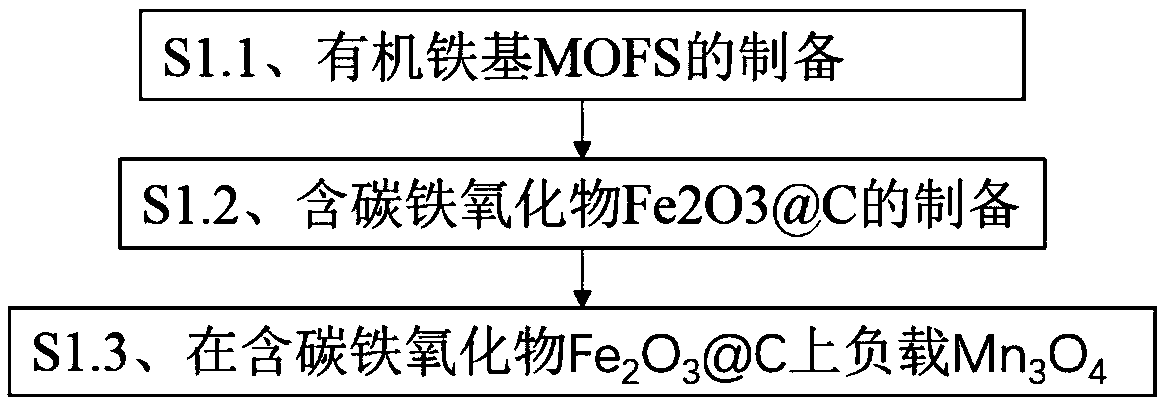

[0034] The step S1 is specifically:

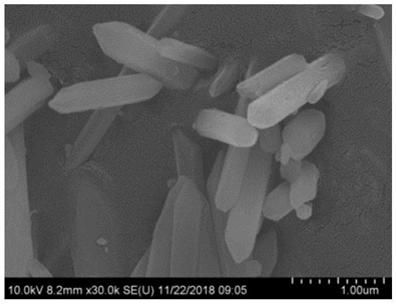

[0035] S1.1. Preparation of organoiron-based MOFS: Weigh 1.741g fumaric acid and 4.050g ferric chloride hexahydrate, the molar ratio of the two is 1:1; weigh the fumaric acid and hexahydrate Dissolve ferric chloride in 80mL deionized water, stir magnetically for 30 minutes, and control the rotation speed at 250r / min; place the obtained mixed solution in a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner in an ordinary oven at 85°C The iron-based MOFS was synthesized by heating and reacting for 12 hours; the obtained pale pink powder iron-based MOFS precipitate was washed with deionized water for 2-3 times, ...

Embodiment 2

[0055] Example 2 of the present invention provides the application of the carbon-containing iron-manganese bimetallic catalyst prepared in Example 1 to degrade acid orange 7.

[0056] 1. The influence of the amount of catalyst added

[0057] Researched the different additions of carbon-containing iron-manganese bimetallic catalysts to the Mn of the present invention 3 o 4 / Fe 2 o 3 Effect of @C / PMS system on degradation of Acid Orange 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com