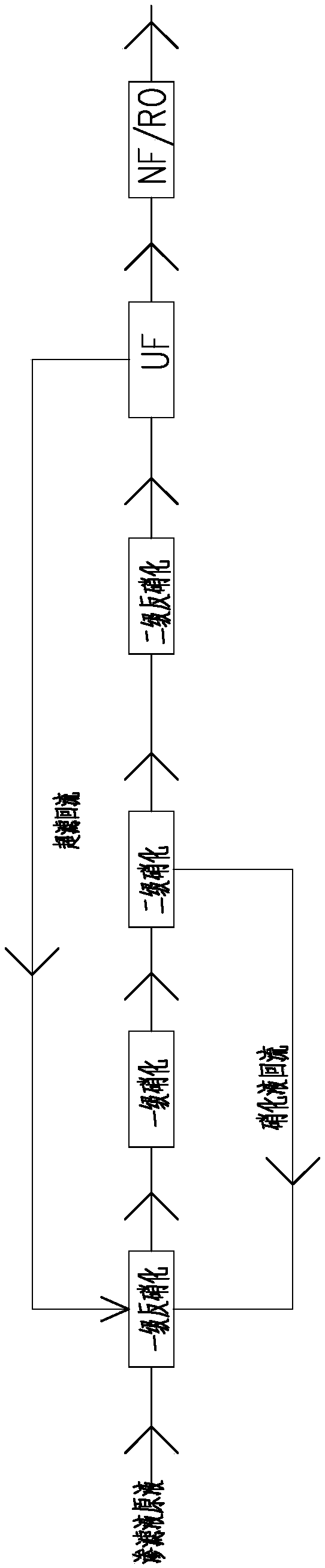

Method for lowering ammonia load in leachate treatment biochemical system

A biochemical system and leachate technology, applied in the field of reducing ammonia load in the biochemical system for treating leachate, can solve the problems of reducing operating costs, insufficient carbon source, nitrifying liquid reflux ratio and large pool capacity, etc., to improve reliability, reduce Fouling and clogging risk, reduced fouling and clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

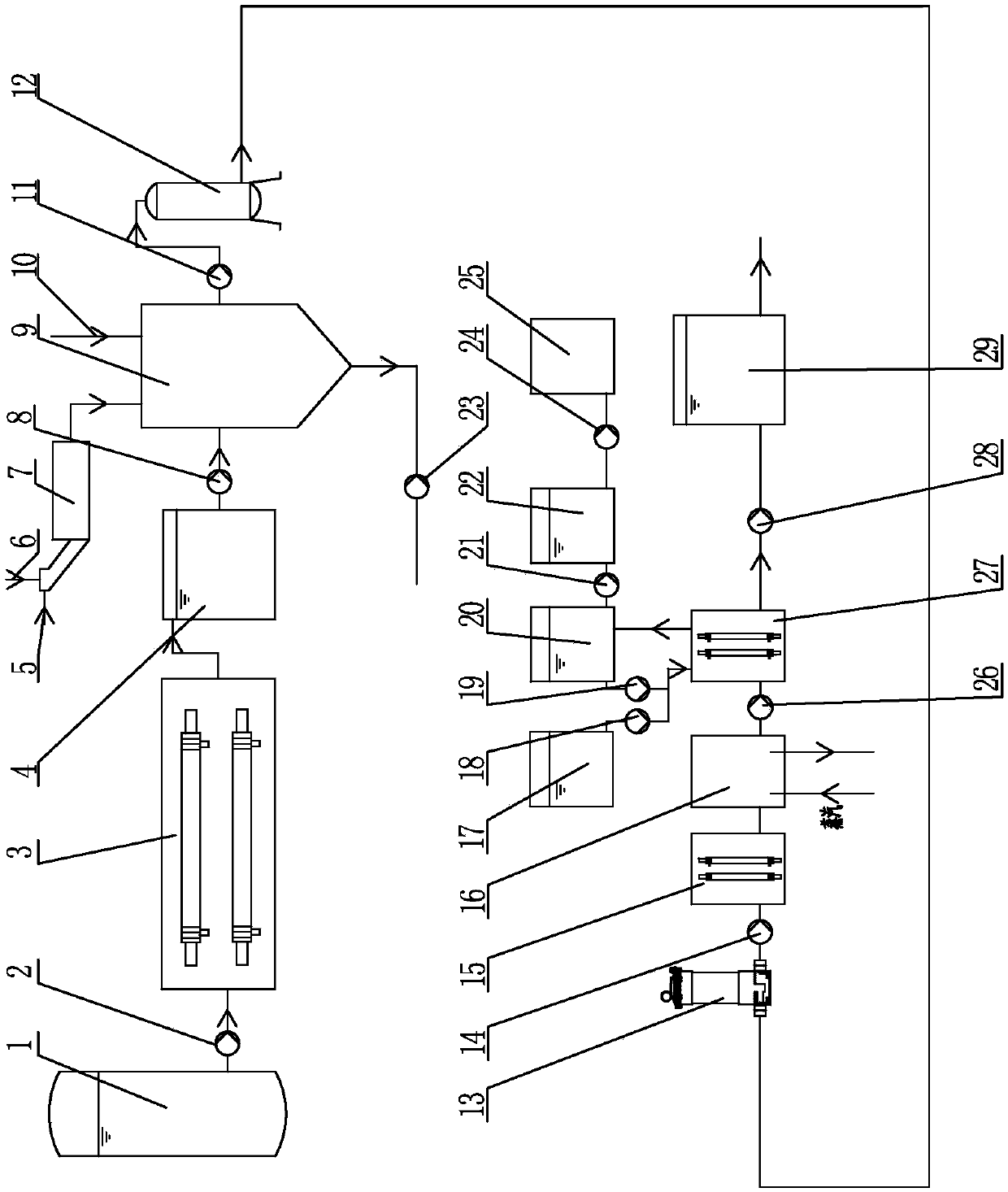

[0041] High ammonia nitrogen wastewater in a denitrification tank 1, the temperature is 36.5°C, the COD concentration is 6200mg / L, the ammonia nitrogen concentration is 3051mg / L, the total nitrogen is 3410mg / L, the total hardness is 3210mg / L, the pH is 8.4, the silica concentration It is 76mg / L, and SS is 13g / L. According to the method for reducing the ammonia load in the leachate biochemical system of the present invention, the treatment is carried out.

[0042] ⑴, ultrafiltration treatment.

[0043] The leachate in the denitrification tank 1 is pumped into the ultrafiltration module 3 through the raw water for ultrafiltration treatment. The filter membrane of the membrane module has a pore size of 20nm and intercepts particulate matter with a particle size greater than 20nm. The working pressure in the tube is 0.58Mpa, and the reflux ratio 13:1, the raw water is separated from mud and water, and the ultrafiltrate is sent to the ultrafiltration storage tank 4, and the ultraf...

Embodiment 2

[0052] High ammonia nitrogen wastewater in a denitrification tank 1, the temperature is 36.9°C, the COD concentration is 5130mg / L, the ammonia nitrogen concentration is 2658mg / L, the total nitrogen is 2990mg / L, the total hardness is 2010mg / L, the pH is 8.9, the silica concentration It is 74mg / L, and SS is 13.6g / L. According to the method for reducing the ammonia load in the leachate biochemical system of the present invention, the treatment is carried out.

[0053] ⑴, ultrafiltration treatment.

[0054] The leachate in the denitrification tank 1 is pumped into the ultrafiltration module 3 through the raw water for ultrafiltration treatment. The filter membrane of the membrane module has a pore size of 15nm, and the particulate matter with a particle size greater than 15nm is retained. The working pressure in the tube is 0.5Mpa. The ratio is 13:1, the raw water is separated from mud and water, and the sludge and suspended matter are intercepted. The ultrafiltrate is sent to th...

Embodiment 3

[0063] High ammonia nitrogen wastewater in a denitrification tank 1, the temperature is 38.6°C, the COD concentration is 4860mg / L, the ammonia nitrogen concentration is 2240mg / L, the total nitrogen is 2818mg / L, the total hardness is 2600mg / L, the pH is 8.8, the silica concentration It is 68mg / L, and SS is 12.9g / L. According to the method for reducing the ammonia load in the leachate biochemical system of the present invention, the treatment is carried out.

[0064] ⑴, ultrafiltration treatment.

[0065] The leachate in the denitrification tank 1 is pumped into the ultrafiltration module 3 through the raw water for ultrafiltration treatment. The membrane module filter membrane pore size intercepts particulate matter with a particle size greater than 20nm, the working pressure in the tube is 0.6Mpa, and the reflux ratio is 13: 1. Separating the raw water from mud and water, intercepting sludge and suspended matter, sending the ultrafiltrate to the ultrafiltration storage tank 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com