Preparation method of porous ceramics with concentric holes and porous ceramics

A technology of porous ceramics and concentric holes, applied in the field of ceramics, can solve the problem of no concentric holes, etc., and achieve the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

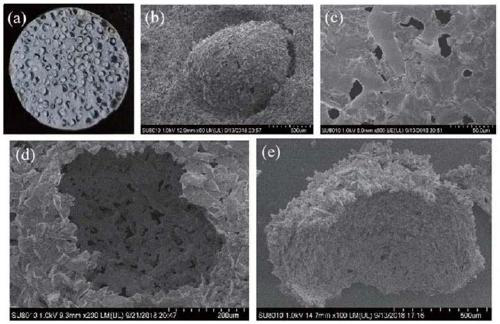

Embodiment 1

[0055] A method for preparing porous ceramics with concentric holes, consisting of the following parts by weight: D 50 60 parts of 37.6μm silicon carbide powder, D 50 40 parts of alumina powder with a diameter of 3.5 μm, 40 parts of soaked millet, 4 parts of acrylamide, 0.4 part of methylenebisacrylamide, 0.015 part of ammonium persulfate, and 0.3 part of dispersant.

[0056] With above-mentioned proportioning, implement according to the following steps:

[0057] (1) Mix the silicon carbide powder, alumina powder, acrylamide, methylenebisacrylamide and dispersant with water evenly, and prepare a stable suspension with a solid phase content of 45 vol.% in a planetary ball mill for 5 hours.

[0058] (2) Soak the millet in water to make it completely swollen and the surface is slightly pulverized, then take it out and dry it in the air until there is no moisture on the surface. Then the processed millet is made into a template, the prepared stable suspension is injected into th...

Embodiment 2

[0063] A porous ceramic with concentric pores, consisting of the following parts by weight: D 50 95 parts of 37.6μm silicon carbide powder, D 50 5 parts of alumina powder with a diameter of 3.5 μm, 42 parts of soaked sorghum rice, 5 parts of acrylamide, 0.5 part of methylenebisacrylamide, 0.015 part of ammonium persulfate, and 0.3 part of dispersant.

[0064] With above-mentioned proportioning, implement according to the following steps:

[0065] (1) Mix the silicon carbide powder, alumina powder, acrylamide, methylenebisacrylamide and dispersant with water evenly, and prepare a stable suspension with a solid phase content of 45 vol.% in a planetary ball mill for 4 hours.

[0066] (2) Soak the sorghum rice in the suspension so that it is completely imbibed and the surface is pulverized, then take it out and dry it in the air until there is no moisture on the surface. Then the processed sorghum rice is made into a template, the prepared stable suspension is injected into the ...

Embodiment 3

[0070] A porous ceramic with concentric pores, consisting of the following parts by weight: D 50 97 parts of alumina powder of 3.5 μm, D 50 3 parts of magnesium oxide powder with a diameter of 2.3 μm, 42 parts of soaked mung beans, 6 parts of acrylamide, 0.6 parts of methylenebisacrylamide, 0.02 parts of ammonium persulfate, and 0.2 parts of dispersant.

[0071] With above-mentioned proportioning, implement according to the following steps:

[0072] (1) Mix alumina powder, magnesium oxide powder, methacrylamide, methylene bisacrylamide and dispersant with water, and planetary ball mill for 4 hours to prepare a stable suspension with a solid content of 50 vol.%.

[0073] (2) Soak the mung bean in the suspension to make it completely swollen and the surface is slightly pulverized, then take it out and dry it in the air until there is no moisture on the surface. Then the soaked mung beans are made into a template, the prepared stable suspension is injected into the template, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com