High-thermal-conductivity and high-tensile-elasticity-modulus polyimide film and preparing method thereof

A technique for stretching elastic modulus and polyimide film, which is applied in the field of high thermal conductivity and high tensile elastic modulus polyimide film and its preparation, can solve the problem of surface property deterioration of polyimide film, inorganic nanomaterials Problems such as poor dispersion and application limitations of polyimide films can improve mechanical properties, improve compatibility, and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

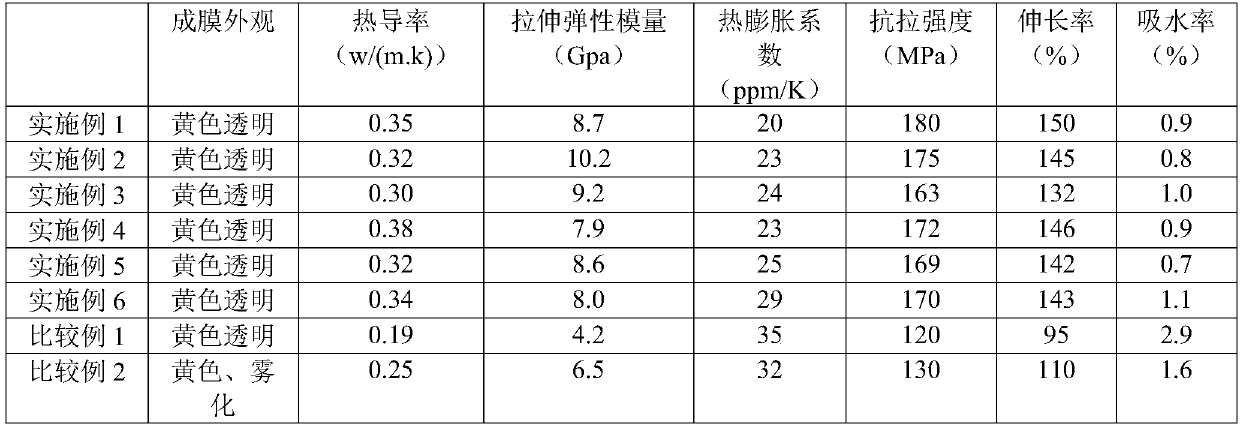

Examples

Embodiment 1

[0026] Add 6g of boron nitride powder (average particle size 3μm) into 100ml of ethanol solution, stir and mix for 30min in a constant temperature water bath at 25°C with a stirring speed of 250rpm to obtain a boron nitride alcohol solution, and add 24g of silane to the boron nitride alcohol solution With coupling agent KH550, raise the reaction temperature to 80°C, then stir and react at a stirring speed of 250rpm / min for 4h, and cool to room temperature to obtain a mixed solution. The mixture was centrifuged at a centrifugal speed of 4000rpm / min for 10min, and the centrifuged liquid was removed to obtain a solid modified boron nitride modified by silsesquisilane, and the modified boron nitride was placed in a vacuum drying oven at 50°C for 2h in vacuo to obtain Silicone modified boron nitride powder;

[0027] Add 15 g of dried siloxane-modified boron nitride powder into 85 g of N, N-dimethylacetamide, and pass N at a stirring speed of 250 rpm / min. 2 Stir for 30 minutes unde...

Embodiment 2

[0031]Add 8g of boron nitride powder (average particle size 5μm) into 100ml of ethanol solution, stir and mix for 30min in a constant temperature water bath at 25°C at a stirring speed of 100rpm to obtain a boron nitride alcohol solution, and add 24g of silane to the boron nitride alcohol solution With coupling agent KH792, raise the reaction temperature to 80°C, then stir and react at a stirring speed of 250rpm / min for 4h, and cool to room temperature to obtain a mixed solution. The mixture was centrifuged at a centrifugal speed of 4000rpm / min for 10min, and the centrifuged liquid was removed to obtain a solid modified boron nitride modified by silsesquisilane, and the modified boron nitride was placed in a vacuum drying oven at 50°C for 2h in vacuo to obtain Silicone modified boron nitride powder;

[0032] Add 15 g of dried siloxane-modified boron nitride powder into 85 g of N, N-dimethylacetamide, and pass N at a stirring speed of 300 rpm / min. 2 Stir for 30 minutes under p...

Embodiment 3

[0036] Add 5g of boron nitride powder (average particle size 5μm) into 100ml of methanol solution, stir and mix for 10min in a constant temperature water bath at 25°C at a stirring speed of 300rpm to obtain a boron nitride alcohol solution, and add 10g of silane to the boron nitride alcohol solution With coupling agent KH560, raise the reaction temperature to 80°C, then stir and react at a stirring speed of 250rpm / min for 4h, and cool to room temperature to obtain a mixed solution. The mixture was centrifuged at a centrifugal speed of 4000rpm / min for 10min, and the centrifuged liquid was removed to obtain a solid modified boron nitride modified by silsesquisilane, and the modified boron nitride was placed in a vacuum drying oven at 50°C for 2h in vacuo to obtain Silicone modified boron nitride powder;

[0037] Add 15 g of dried siloxane-modified boron nitride powder into 85 g of N, N-dimethylacetamide, and pass N at a stirring speed of 300 rpm / min. 2 Stir for 30 minutes under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com