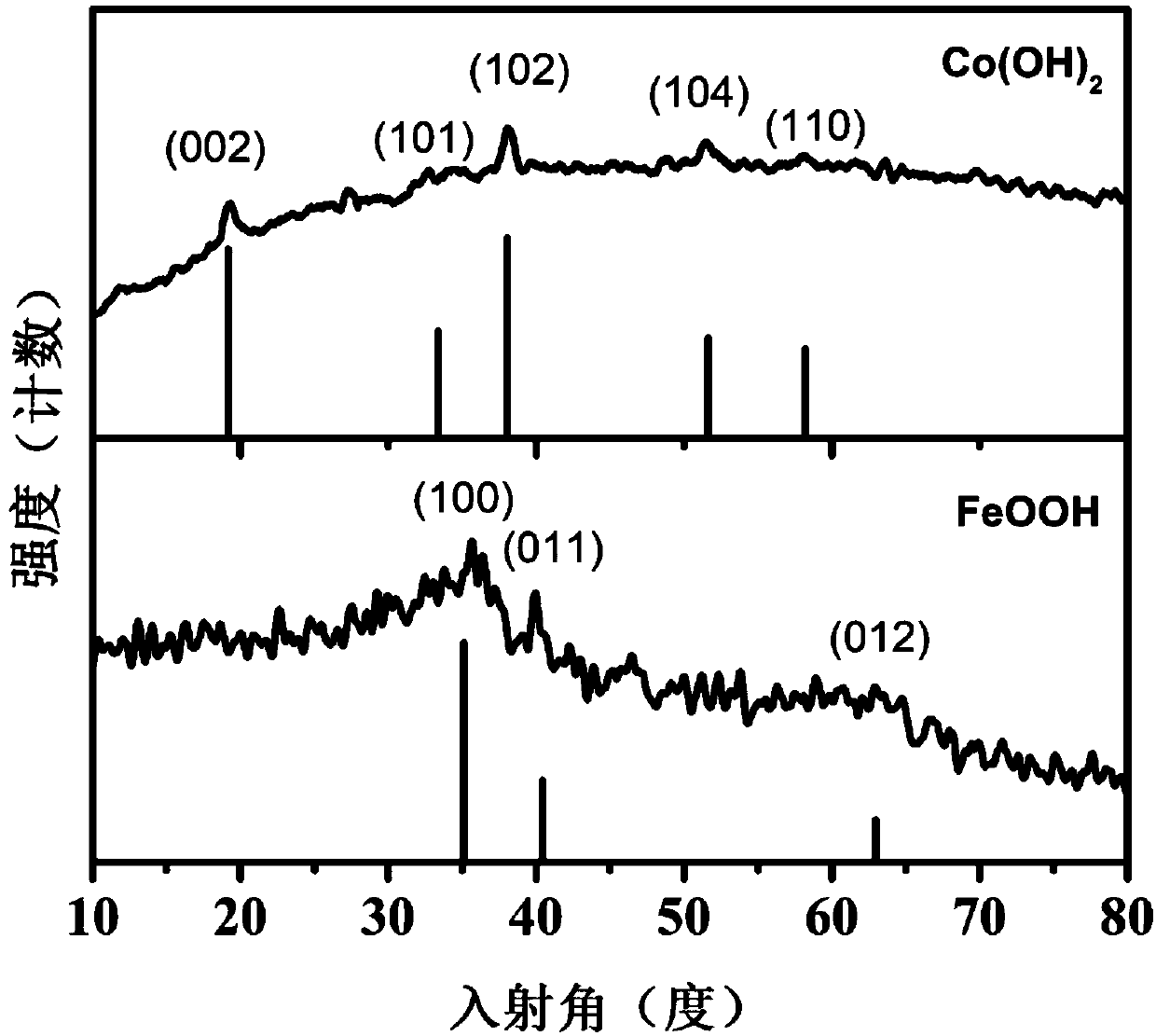

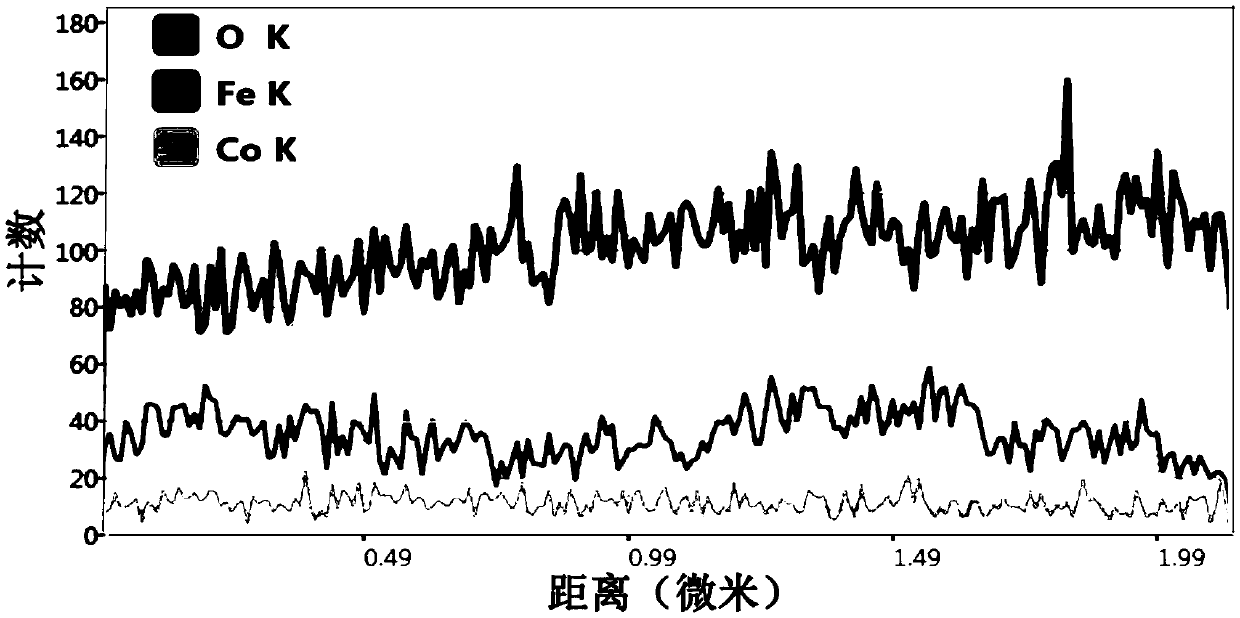

Oxygen evolution reaction FeOOH/Co(OH)2 composite electrocatalyst preparation method

An oxygen evolution reaction and electrocatalyst technology, applied in electrodes, circuits, electrical components, etc., can solve the problems of poor dispersion and poor electrocatalytic performance of oxygen evolution reaction, and achieve convenient operation, improved electrocatalytic performance, and high electrocatalytic performance. and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

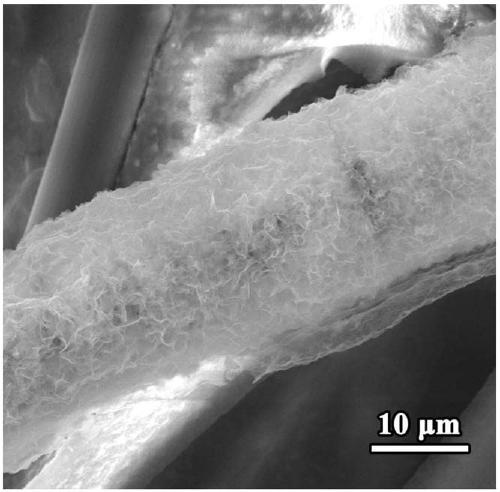

[0032] Step 1: Dissolve an appropriate amount of cobalt nitrate in a certain volume of deionized water, stir at 25°C for 15 minutes, and use the prepared cobalt nitrate solution (0.1mol / L) as the electrolyte;

[0033]Step 2: Cut carbon fiber paper with a thickness of 0.3mm into 1*2cm long strips and heat in a water bath at 60°C for 2 hours in a 1mol / L potassium hydroxide solution, then ultrasonically in absolute ethanol and deionized water for 30 minutes, take out Finally, dry in an oven at 60°C for 3 hours;

[0034] Step 3: Use the electrode holder to clamp the carbon fiber paper treated in step 2 as the working electrode, the platinum-coated titanium mesh (2*3cm) as the counter electrode, the saturated calomel electrode as the reference electrode, and the cobalt nitrate solution in step 1 as the electrolyte , carry out step-by-step constant voltage deposition; the first deposition voltage is -1.1V, the deposition time is 100s, and then the second step deposition is performed...

Embodiment 2

[0041] Other steps are the same as in Example 1, except that the number of deposition circles in step 3 is changed from 1 circle to 2 circles.

Embodiment 3

[0043] Other steps are the same as in Example 1, except that the number of deposition circles in step 3 is changed from 1 circle to 3 circles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com