Nitrogen and phosphorus removal composite adsorption material and preparation method thereof

A composite adsorption material and a technology for denitrification and phosphorus removal, which are applied in the field of composite adsorption materials for denitrification and phosphorus removal and the field of preparation thereof, can solve problems such as large energy consumption, and achieve reduced carbon pollution, good removal effect and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

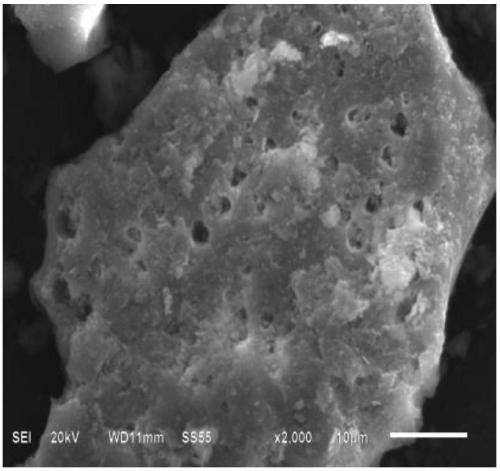

[0029] The invention provides a composite adsorption material for denitrification and phosphorus removal. The composite adsorption material is prepared from pomelo peel, iron rust, waste hydrochloric acid and aluminum sludge.

[0030] A preparation method for a composite adsorption material for nitrogen and phosphorus removal, comprising the steps of:

[0031] (1) Aluminum sludge pretreatment: dehydrate the aluminum sludge, air-dry it to reduce the moisture content to below 40wt%, and then place it in an oven at 105°C for further drying for 8 hours, grind it into fine powder, and sieve through a 100-mesh sieve.

[0032] (2) Pretreatment of grapefruit peel: air-dry grapefruit peel, crush it into a ceramic crucible, compact it lightly, cover it, put it in a muffle furnace, keep it at 400°C for 3.5 hours, and wait for the muffle Cool in the furnace to room temperature, take out the carbonized pomelo peel, grind and sieve to 100 mesh, set aside.

[0033] (3) Preparation of modifi...

Embodiment 2

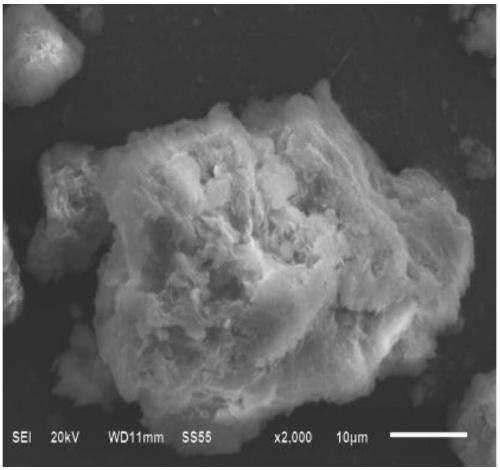

[0038] The difference between this embodiment and Example 1 is that the carbonized pomelo peel, iron rust, waste hydrochloric acid and deionized water are mixed in a ratio of 1kg: 1.2g: 6g: 20L, and Fe in the iron rust 2 o 3 The content of HCl is 91%, the content of HCl in waste hydrochloric acid is 19%, and the mass fraction of aluminum element in aluminum sludge is 11%.

[0039] The same test method as in Example 1 was used to measure the total phosphorus removal rate of the composite adsorbent material prepared in this example to be 97%, the total nitrogen removal rate to be 78%, and the ammonia nitrogen removal rate to be 90%.

Embodiment 3

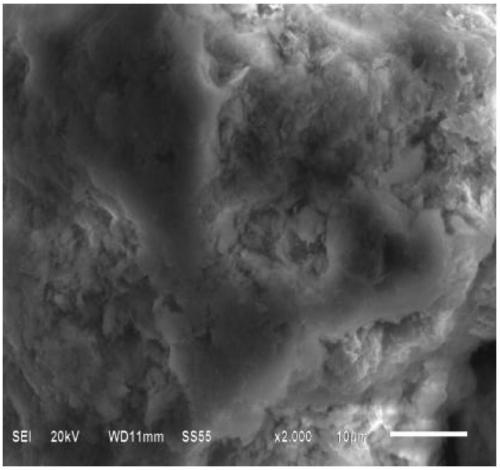

[0041] The carbonized pomelo peel, iron rust, waste hydrochloric acid and deionized water are mixed in the ratio of 1kg: 1.5g: 7g: 20L, and Fe in the iron rust 2 o 3 The content of HCl is 92.5%, the content of HCl in waste hydrochloric acid is 23%, and the mass fraction of aluminum element in aluminum sludge is 12%.

[0042] The same test method as in Example 1 was used to measure the removal rate of total phosphorus, 78% of total nitrogen and 88% of ammonia nitrogen of the composite adsorbent material prepared in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com