Preparing method of graphene aerogel/polyurethane foam conductive composite

A conductive composite material, graphene aerogel technology, applied in the direction of graphene, chemical instruments and methods, ceramic products, etc., can solve the problems of poor mechanical properties of aerogels, high production costs, and difficulty in meeting application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

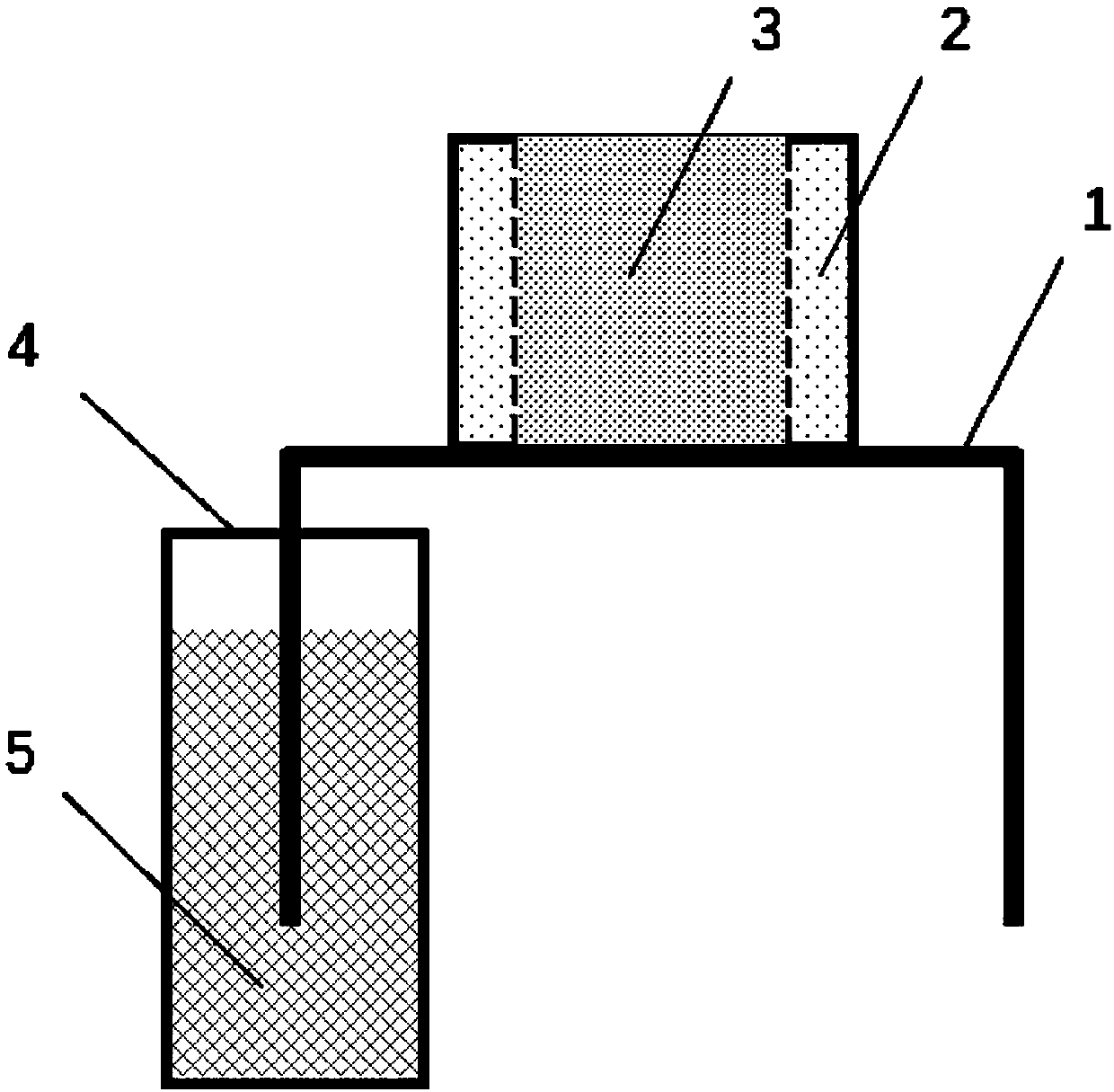

Image

Examples

preparation example Construction

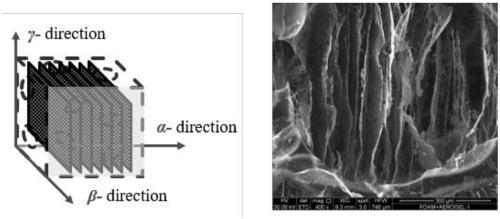

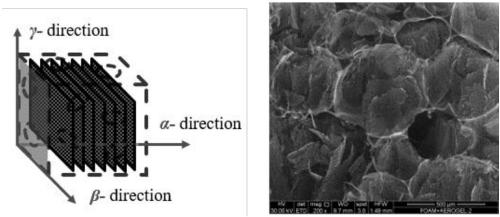

[0036] The invention provides a method for preparing a graphene aerogel / polyurethane foam conductive composite material, which includes the following steps:

[0037] Step S1: preparing graphene oxide dispersion: adding graphene oxide prepared by the improved Hummer’s method to deionized water, ultrasonicating for 30 minutes, to prepare a uniform dispersion of graphene oxide with a concentration of 1-10 wt.%;

[0038] Step S2: Preparation of chitosan solution: pour the solid chitosan powder into the acetic acid solution with a volume fraction of 1 vol.%, and mechanically stir at 500-1000 rpm until it is completely dissolved, and then the obtained chitosan The solution is centrifuged at 500-1000 rpm for 2-10 minutes to remove insoluble solid impurities and prepare a chitosan solution with a concentration of 1-20wt.%;

[0039] Step S3: Preparation of graphene oxide / chitosan solution: the graphene oxide dispersion obtained in step 1 and the chitosan solution prepared in step 2 are adjust...

Embodiment 1

[0047] Step 1, preparing graphene oxide dispersion: adding 1 g of graphene oxide prepared by the improved Hummer’s method to 10 mL of deionized water, and ultrasonically dispersing for 30 minutes until uniformly dispersed, to obtain a graphene oxide dispersion with a concentration of 10 wt.%;

[0048] Step two, prepare the chitosan solution: pour 25g of medium molecular weight chitosan powder into 250mL of 1vol.% acetic acid solution, mechanically stir at 800 rpm for 12 hours until completely dissolved, and then 500 rpm Centrifugal separation at a speed of 10 minutes per minute to remove insoluble impurities and obtain a chitosan solution with a concentration of 10 wt.%;

[0049] Step three: prepare graphene / chitosan solution: mix the graphene oxide dispersion obtained in step one with the chitosan solution prepared in step two at a mass ratio of 1:1, and continue to mechanically stir for 60 minutes until mixed under ultrasound Evenly

[0050] Step 4: Filling the open-cell polyureth...

Embodiment 2

[0058] Step 1: Prepare graphene oxide dispersion: add 0.5 g of graphene oxide prepared by the improved Hummer's method to 10 mL of deionized water, and ultrasonically disperse for 30 minutes until uniformly dispersed, to obtain a graphene oxide dispersion with a concentration of 5 wt.% ;

[0059] Step two: preparing chitosan solution: pour 25 g of medium molecular weight chitosan powder into 250 mL of 1 vol.% acetic acid solution, and mechanically stir at 800 rpm for 12 hours to completely dissolve. Then centrifuge at a speed of 500 rpm for 10 minutes to remove insoluble impurities and obtain a chitosan solution with a concentration of 10 wt.%;

[0060] Step three: prepare graphene / chitosan solution: mix the graphene oxide dispersion obtained in step one with the chitosan solution prepared in step two at a mass ratio of 1:1, and continue to mechanically stir for 60 minutes until mixed under ultrasound Evenly

[0061] Step 4: Filling the open-cell polyurethane foam with graphene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com