Controllable biodegradable copolymer material and preparation method and application thereof

A biodegradable and copolymer technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of material elongation at break, material tensile strength decrease, slow biodegradation, poor hydrophilicity of copolymer, etc. High expansion ratio, high mechanical strength, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

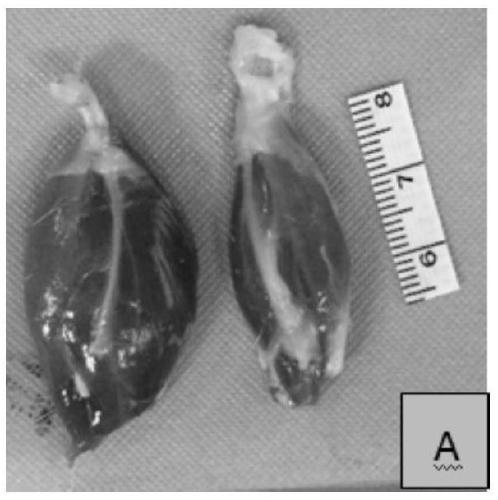

Image

Examples

Embodiment 5-9 3

[0044] Copolymer P(LA-co-CL-co-TMC) of embodiment 5-9 trimethylene carbonate

[0045] Table 2 embodiment 9-12 formula and reaction condition thereof

[0046]

[0047] Preparation method: Mix trimethylene carbonate, L-, D-lactide, and caprolactone and add them to the reactor. After mixing, repeatedly vacuumize and fill with nitrogen for 20 times; add to the reactor under nitrogen atmosphere Ring-opening polymerization catalyst, heating the reactor to the corresponding temperature, and reacting for a certain period of time; cooling the reactor, adding it into dichloromethane for dissolution, and then precipitating in absolute ethanol, and drying the precipitated product.

Embodiment 10

[0052] The tensile property research of embodiment 10 copolymers

[0053] Table 3 copolymer performance and its tensile performance comparison

[0054]

[0055] Lactide L / D in the above table refers to the feed ratio when L-lactide and D-lactide are polymerized

[0056] The detection of polymer intrinsic viscosity is based on GB / T 1632.1-2008 plastics using a capillary viscometer to measure the viscosity of dilute polymer solutions. Part: The test conditions for thin plastics and thin sheets are carried out. Dispersion is determined by GPC.

[0057] As can be seen from Table 3, in the 4 kinds of copolymers provided by the present invention, adding multi-arm copolymerization center and trimethylene carbonate compared with the non-added copolymer (comparative example 1-2), tensile strength and elongation at break are both increased, indicating that the copolymer provided by the present invention has high mechanical strength and strong flexibility.

Embodiment 11

[0058] The degradation cycle research of embodiment 11 copolymer

[0059] Table 4 trimethylene carbonate copolymer and its performance comparison

[0060]

[0061] Note: Degradation test is carried out according to YY / T 0473-2004 Surgical implant polylactide copolymer and blend in vitro degradation test

[0062] It can be seen from Table 4 that the degradation period of the copolymer containing multi-arm center and trimethylene carbonate can be shortened by 6 weeks and 7 weeks respectively than that of the copolymer not containing trimethylene carbonate. In the process, it can avoid the swelling caused by the copolymer not degrading for a long time in the body, which will damage human health. The degradation time of the two copolymers can be adjusted by adjusting the ratio of caprolactone and trimethylene carbonate, so as to meet different clinical requirements for degradation time in various fields of application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com