Process system and process method for washing desalination and oil-water separation

A process system and separation system technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as poor mixing of injected water and oil, difficulty in achieving washing and desalting effects, and poor deep separation of oil and water. , to achieve good applicability and use effect, small equipment size and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

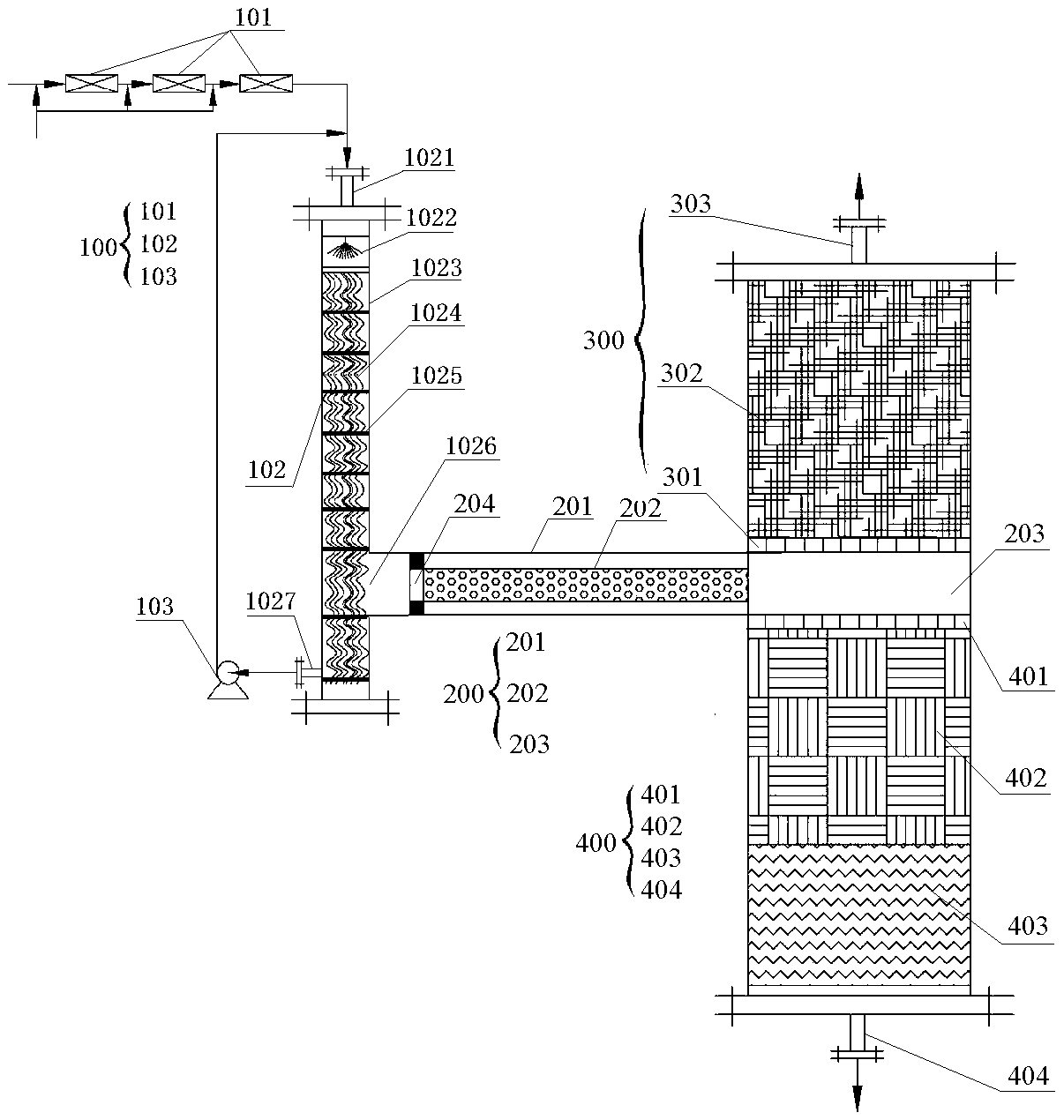

[0042] A process system for washing desalination and oil-water separation, such as figure 1 As shown, it includes a pre-mixed washing system 100, a pre-separation system 200, a light phase separation system 300 and a heavy phase separation system 400;

[0043] The premixed washing system 100 includes a mixer 101 and a fiber membrane washing assembly 102, the mixer 101 is connected to the fiber membrane washing assembly inlet 1021, and the fiber membrane washing assembly 102 includes a housing 1023, a distributor 1022 and a fiber membrane Membrane bundle 1024, distributor 1022 is a shower head type, the upper end is connected to the feed port 1021 of the fiber membrane washing assembly, and several fiber membrane bundles 1024 are arranged below the distributor 1022. The fiber membrane bundle 1024 includes a large number of bundled fiber filaments, and the fiber filaments are polyester Composite fiber filaments of fiber filaments and stainless steel fiber filaments, fiber film b...

Embodiment 2

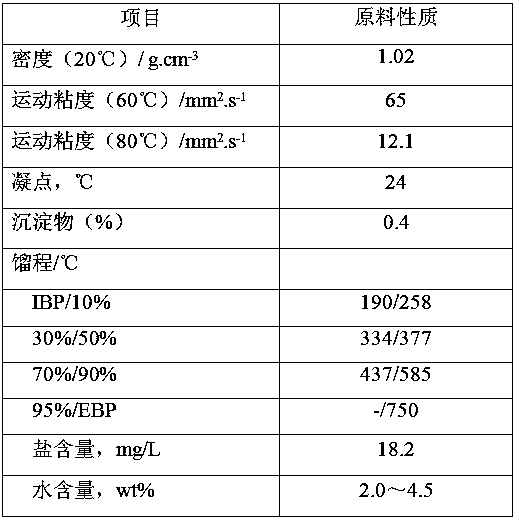

[0050] Use the process system of Example 1 to wash and desalt the oil (where water is the heavy phase) and separate the oil from water: the material to be treated is poured into the mixer 101, water is added to it and pre-mixed by force, and the fiber membrane washing module feeds 1021 enters the distributor 1022 and contacts with the surface of the fiber membrane bundle 1024, the salt in the material to be treated is fully dissolved in water, and part of the material is pumped into the circulation pump 103 through the outlet 2027 of the fiber membrane washing module and continues to enter the fiber membrane washing module 102 Washing and dissolving for many times, part of the material enters the pre-separation system 200 from the shell outlet 1026, and first enters the middle cavity of the hollow filter element 202 from the feed pipe inlet 204. Under the action of the hollow filter element 202, the oil in the oil Large water droplets are separated and left in the middle of the...

Embodiment 3

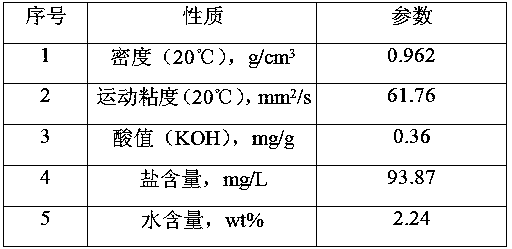

[0053] The process system of Example 1 was used to desalt and dehydrate crude oil (see Table 1 for properties of crude oil), and the operation process was as described in Example 2. The specific operating conditions are: operating temperature: 110-115°C; operating pressure: 0.5-0.8MPaG; total residence time: 13 minutes; water injection volume is 3% of the mass of raw oil.

[0054] After washing, desalting and oil-water separation, the salt content in the oil is 2.76mg / L-2.93mg / L, and the water content is 380ppm-498ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com