Device and method for preparing methane by coal catalytic gasification in fluidized bed with nozzles

A fluidized bed gasifier, fluidized bed technology, applied in the details of gasification device, gasification process, granular/powdered fuel gasification, etc., can solve the problems of low carbon conversion rate, low methane yield and operating cost Advanced problems, to achieve the effect of increasing carbon conversion rate, increasing methane yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

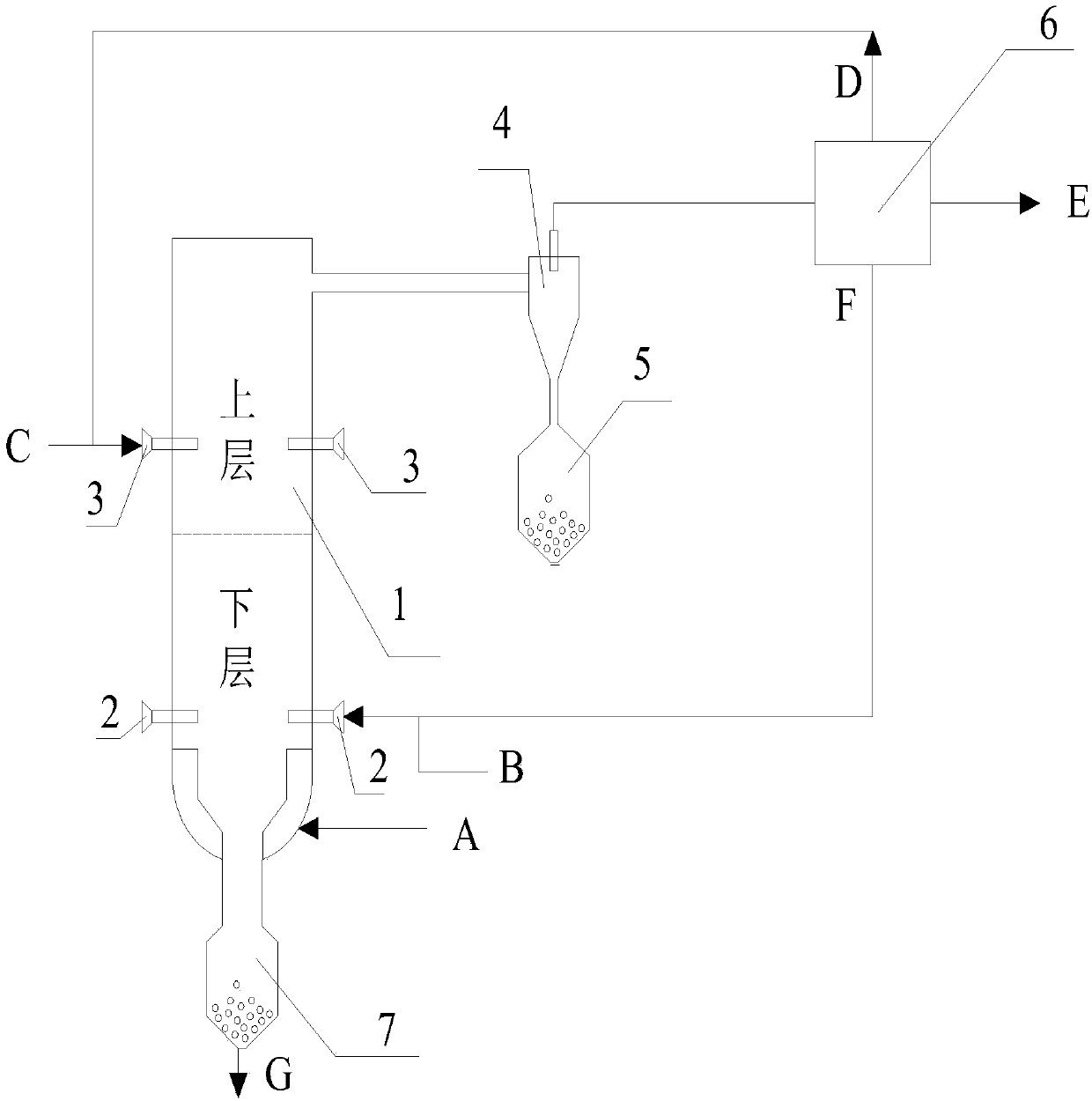

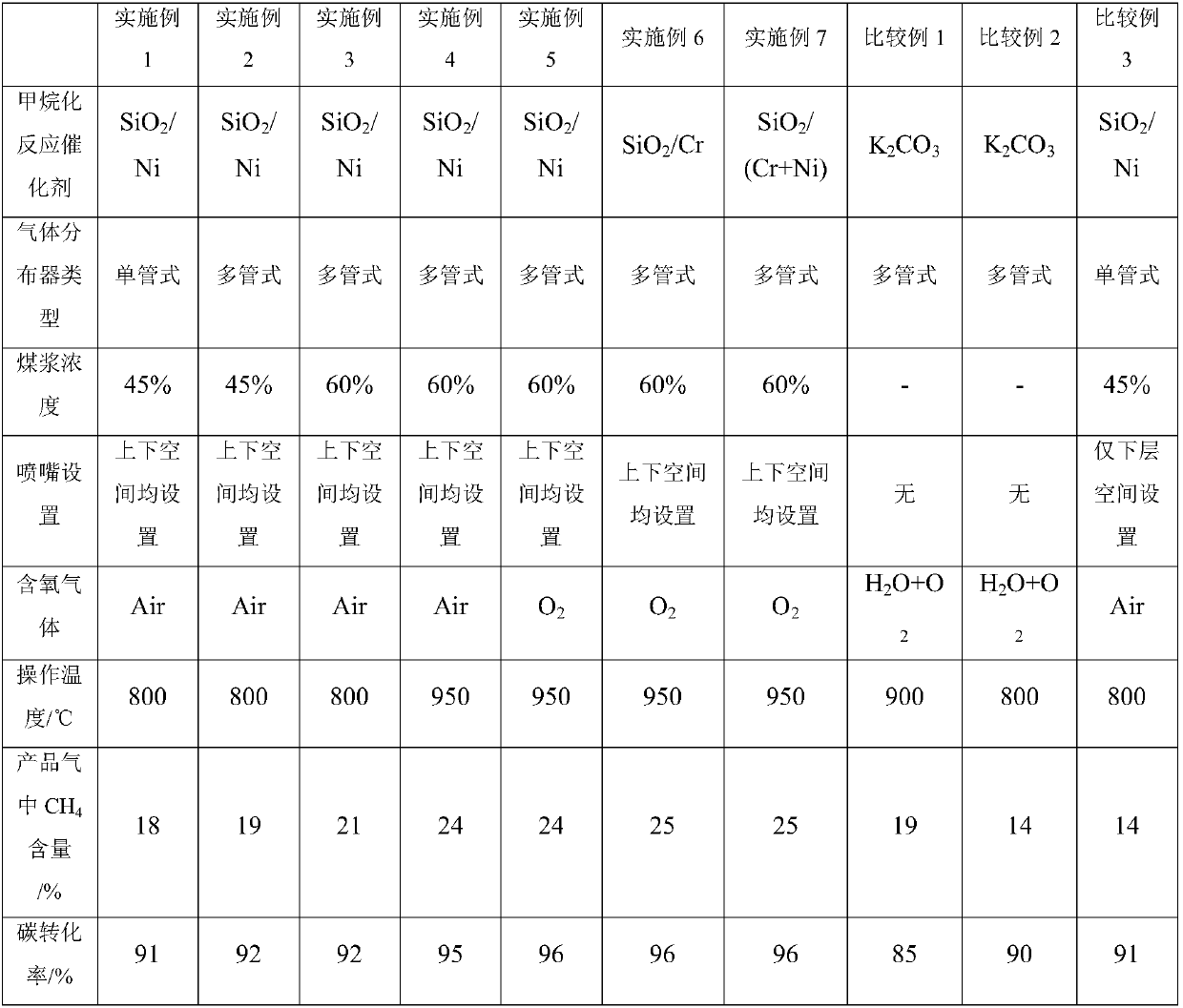

Embodiment 1

[0026] In this embodiment, the oxygen-containing gas (A) is air, and is introduced into the fluidized bed gasifier through a single-pipe jet gas distributor, and the gas distributor is arranged perpendicular to the bottom of the fluidized bed gasifier. In this embodiment, the raw material of coal slurry with a concentration of 45% is put into the lower space of the gasifier through the first nozzle, and gasification reaction occurs at an operating temperature of 800°C, and the ash generated by the reaction falls into the slag hopper due to its own gravity in the middle; while the syngas enters the upper space upwards, and is injected by the SiO2 from the second nozzle 2 / Ni catalyst contact, catalytic methanation reaction occurs, generating rich CH 4 product gas. The product gas carries the fine fly ash particles in the furnace into the gas-solid separation equipment for separation, the fly ash particles are sent to the ash hopper for collection, and the product gas is sent t...

Embodiment 2

[0028]In this embodiment, the oxygen-containing gas (A) is air, and is introduced into the fluidized bed gasifier through a multi-pipe jet gas distributor, and the gas distributor is arranged perpendicular to the bottom side of the fluidized bed gasifier. In this embodiment, the raw material of coal slurry with a concentration of 45% is put into the lower space of the gasifier through the first nozzle, and gasification reaction occurs at an operating temperature of 800°C, and the ash generated by the reaction falls into the slag hopper due to its own gravity in the middle; while the syngas enters the upper space upwards, and is injected by the SiO2 from the second nozzle 2 / Ni catalyst contact, catalytic methanation reaction occurs, generating rich CH 4 product gas. The product gas carries the fine fly ash particles in the furnace into the gas-solid separation equipment for separation, the fly ash particles are sent to the ash hopper for collection, and the product gas is sen...

Embodiment 3

[0030] In this embodiment, the oxygen-containing gas (A) is air, and is introduced into the fluidized bed gasifier through a multi-pipe jet gas distributor, and the gas distributor is arranged perpendicular to the bottom side of the fluidized bed gasifier. In this embodiment, the raw material of coal slurry with a concentration of 60% is put into the lower space of the gasifier through the first nozzle, and the gasification reaction occurs at an operating temperature of 800°C, and the ash generated by the reaction falls into the slag hopper due to its own gravity in the middle; while the syngas enters the upper space upwards, and is injected by the SiO2 from the second nozzle 2 / Ni catalyst contact, catalytic methanation reaction occurs, generating rich CH 4 product gas. The product gas carries the fine fly ash particles in the furnace into the gas-solid separation equipment for separation, the fly ash particles are sent to the ash hopper for collection, and the product gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com