Breathable and impermeable blanket and production process thereof

A technology of breathable anti-seepage blanket and production process, which is applied in marine engineering, layered products, water conservancy projects, etc., can solve the problems of easy leakage of breathable anti-seepage particles and more dust, and achieves convenient construction, less dosage, and less usage. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

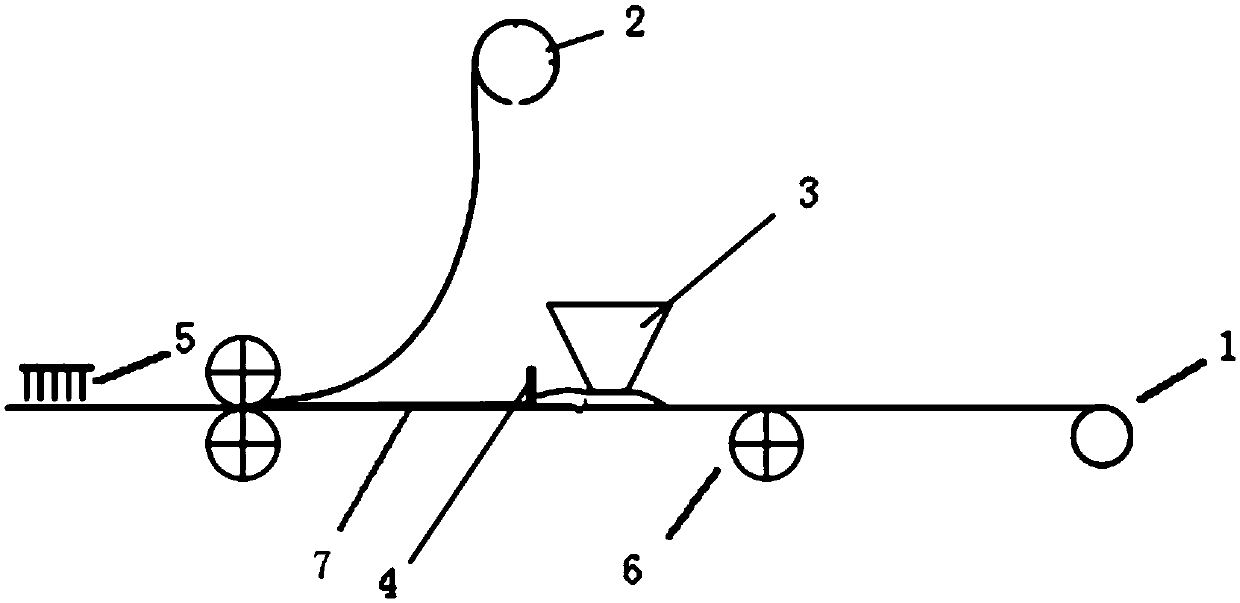

Method used

Image

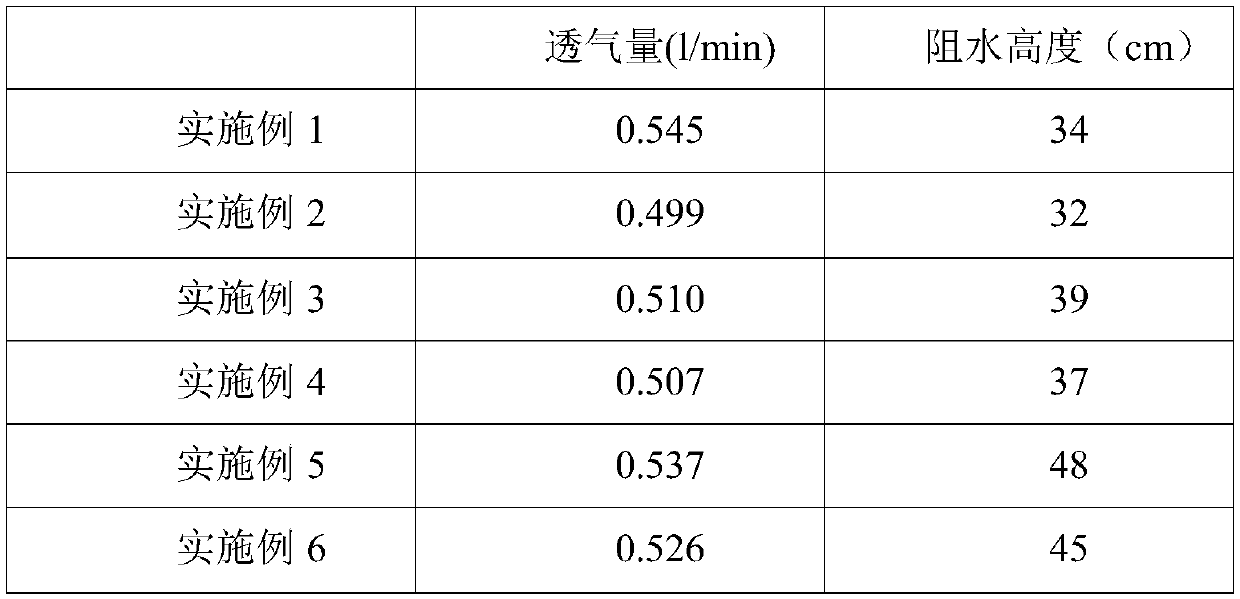

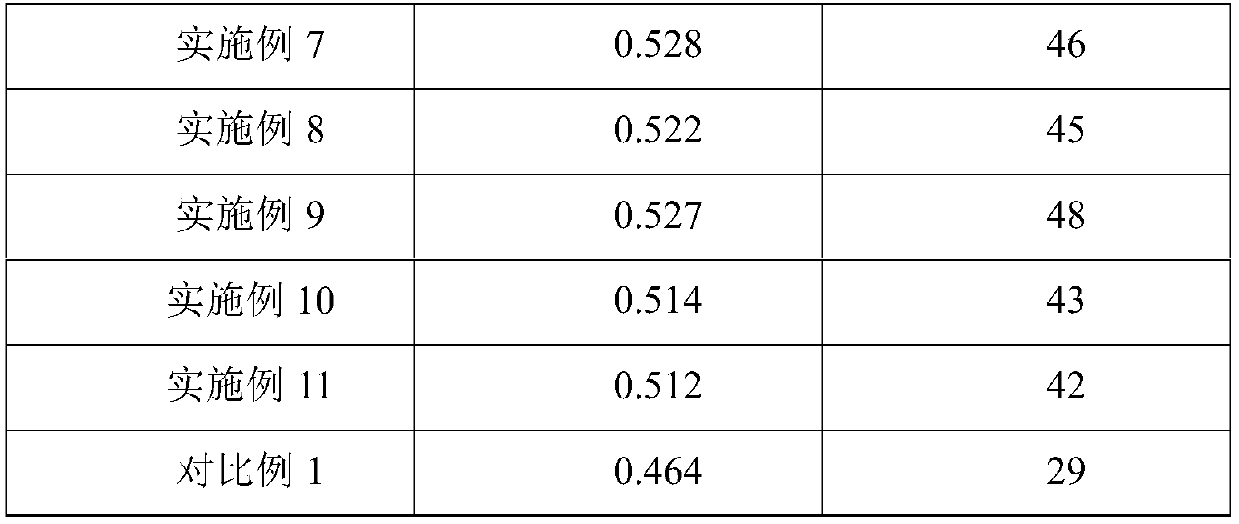

Examples

Embodiment 1

[0076] This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower air-permeable fiber cloth; the air-permeable anti-seepage sand layer contains air-permeable anti-seepage particles and expansive particles; the addition of the expansive particles accounts for 0.1% of the mass of the air-permeable anti-seepage particles; The particle diameter of the breathable and anti-seepage particles is 1mm; the expansive particle is bentonite with a particle diameter of 5mm.

[0077] The air-permeable anti-seepage particles contain aggregate quartz sand and polyvinyl alcohol tert-butyraldehyde modified epoxy resin covering the aggregate. The polyvinyl alcohol tert-butyraldehyde modified epoxy resin is 0...

Embodiment 2

[0087] This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower woven cloth; the air-permeable anti-seepage sand layer contains air-permeable anti-seepage particles and expansive particles; the addition of the expansive particles accounts for 1000% of the mass of the air-permeable anti-seepage particles; The particle size of the breathable and anti-seepage particles is 0.045mm; the expandable particles are clay with a particle size of 0.001mm.

[0088] The air-permeable and anti-seepage particles contain aggregate quartz sand and polyamide resin modified epoxy resin covering the aggregate. The polyamide resin modified epoxy resin is 10wt% of the mass of quartz sand.

[0089] The prepar...

Embodiment 3

[0098]This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower air-permeable fiber cloth; the air-permeable anti-seepage sand layer includes air-permeable anti-seepage particles and expansive particles; the addition of the expansive particles accounts for 5% of the mass of the air-permeable anti-seepage particles; The particle size of the breathable and anti-seepage granules is 0.1 mm; the expansive particles are clay with a particle size of 0.075 mm.

[0099] The air-permeable and anti-seepage particles contain aggregate quartz sand and polyamide resin modified epoxy resin covering the aggregate. The polyamide resin modified epoxy resin is 3wt% of the mass of quartz sand.

[0100] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com