A kind of lithium cobalt phosphate cathode material and preparation method for lithium ion battery

A lithium-ion battery, lithium cobalt phosphate technology, applied in battery electrodes, phosphates, phosphorus oxyacids, etc., can solve problems such as poor conductivity, unstable cycle performance, and reduced electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

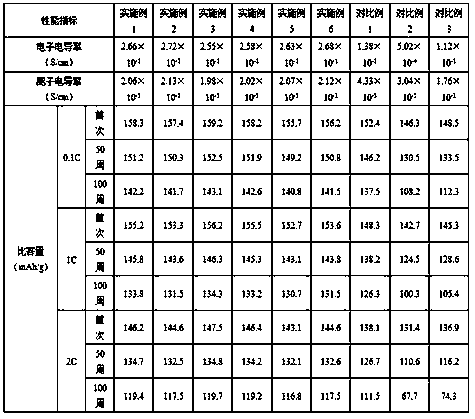

Examples

Embodiment 1

[0032](1) Add polyvinylidene fluoride to N-methylpyrrolidone, stir until completely dissolved, then add modified multi-walled carbon nanotubes, ultrasonically disperse for 28 minutes, then add lithium phosphate, cobalt tetroxide, and ferric oxide, and transfer to a ball mill Ball milling is carried out in the tank; the parts by weight of each raw material are: 1 part by weight of polyvinylidene fluoride, 69 parts by weight of N-methylpyrrolidone, 5 parts by weight of modified multi-walled carbon nanotubes, 10 parts by weight of lithium phosphate, and 12 parts by weight of tricobalt tetroxide , 3 parts by weight of ferric oxide; the modified multi-walled carbon nanotubes are hydroxylated multi-walled carbon nanotubes; the rotating speed of the ball mill is 1250r / min, and the time is 7h;

[0033] (2) Take out the material in the ball mill tank, heat to remove N-methylpyrrolidone, then grind it into nano-powder, put it in a tube furnace, and sinter at high temperature in an atmosp...

Embodiment 2

[0037] (1) Add polyvinylidene fluoride to N-methylpyrrolidone, stir until completely dissolved, then add modified multi-walled carbon nanotubes, ultrasonically disperse for 25 minutes, then add lithium phosphate, tricobalt tetroxide, and ferric oxide, and transfer to a ball mill Ball milling is carried out in the tank; the parts by weight of each raw material are: 1 part by weight of polyvinylidene fluoride, 70 parts by weight of N-methylpyrrolidone, 4 parts by weight of modified multi-walled carbon nanotubes, 10 parts by weight of lithium phosphate, and 12 parts by weight of tricobalt tetroxide , 3 parts by weight of ferric oxide; the modified multi-walled carbon nanotubes are carboxylated multi-walled carbon nanotubes; the rotating speed of the ball mill is 1250r / min, and the time is 8h;

[0038] (2) Take out the material in the ball mill tank, heat to remove N-methylpyrrolidone, then grind it into nano-powder, put it in a tube furnace, and sinter at high temperature in an at...

Embodiment 3

[0042] (1) Add polyvinylidene fluoride to N-methylpyrrolidone, stir until completely dissolved, then add modified multi-walled carbon nanotubes, ultrasonically disperse for 35 minutes, then add lithium phosphate, cobalt tetroxide, and ferric oxide, and transfer to a ball mill Ball milling is carried out in the tank; the parts by weight of each raw material are: 2 parts by weight of polyvinylidene fluoride, 67 parts by weight of N-methylpyrrolidone, 5 parts by weight of modified multi-walled carbon nanotubes, 10 parts by weight of lithium phosphate, and 13 parts by weight of tricobalt tetroxide , 3 parts by weight of ferric oxide; the modified multi-walled carbon nanotubes are aminated multi-walled carbon nanotubes; the rotating speed of the ball mill is 1350r / min, and the time is 6.5h;

[0043] (2) Take out the material in the ball mill tank, heat to remove N-methylpyrrolidone, then grind it into nano-powder, put it in a tube furnace, and sinter at high temperature in an atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com