Mesoporous platinum-palladium-gold electrocatalyst and preparation method thereof

An electrocatalyst, platinum-palladium-gold technology, applied in the field of mesoporous platinum-palladium-gold electrocatalyst and its preparation, can solve problems such as cumbersome operation steps, achieve great application prospects, high yield, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of mesoporous platinum-palladium-gold electrocatalyst, said method comprising the steps of:

[0035] 1) Potassium chloroplatinite, sodium chloropalladate and chloroauric acid solution with a concentration of 20mM, hydrochloric acid solution with a concentration of 6M and ascorbic acid solution with a concentration of 0.1M;

[0036] 2) Mix 2.4mL of potassium chloroplatinite, 0.8mL of sodium chloropalladate and 0.8mL of chloroauric acid solution, then add 50μL of hydrochloric acid solution, then add 40mg of F127, and ultrasonically dissolve it completely; finally Then add 4 mL of ascorbic acid solution;

[0037] 3) After the solution is evenly mixed, place it in an ultrasonic cleaner and heat it to 40° C. After reacting for 4 hours, wash it with ultrapure water, collect the product by centrifugation, and dry it to obtain a mesoporous platinum-palladium-gold electrocatalyst.

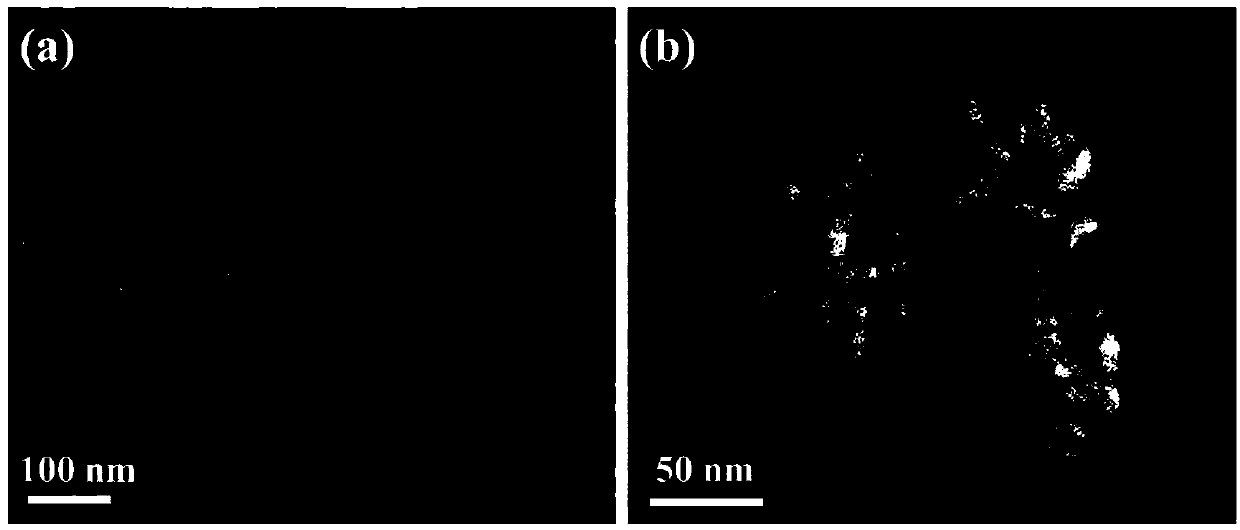

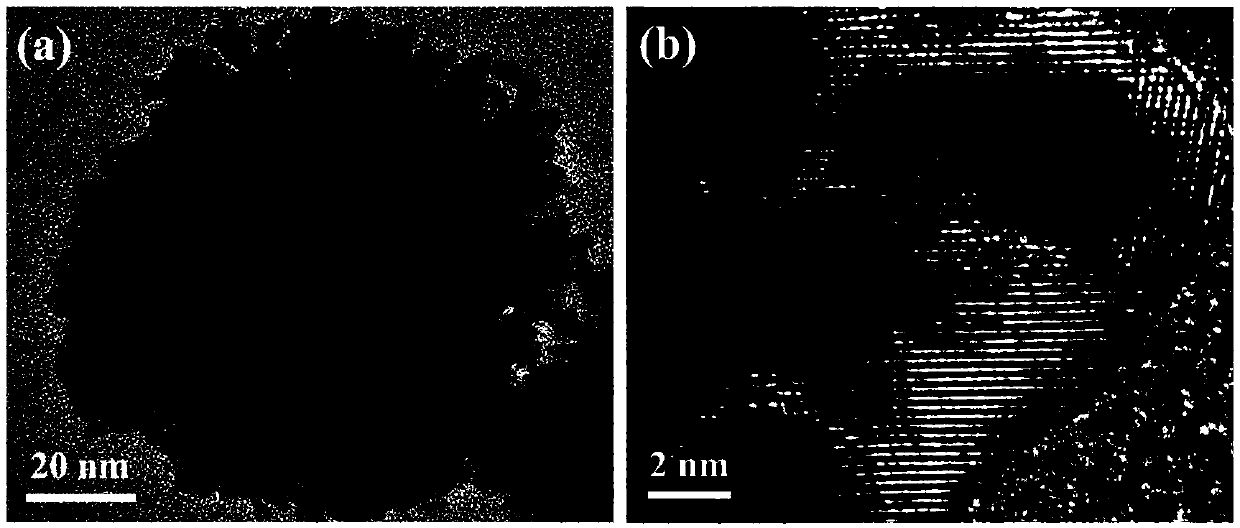

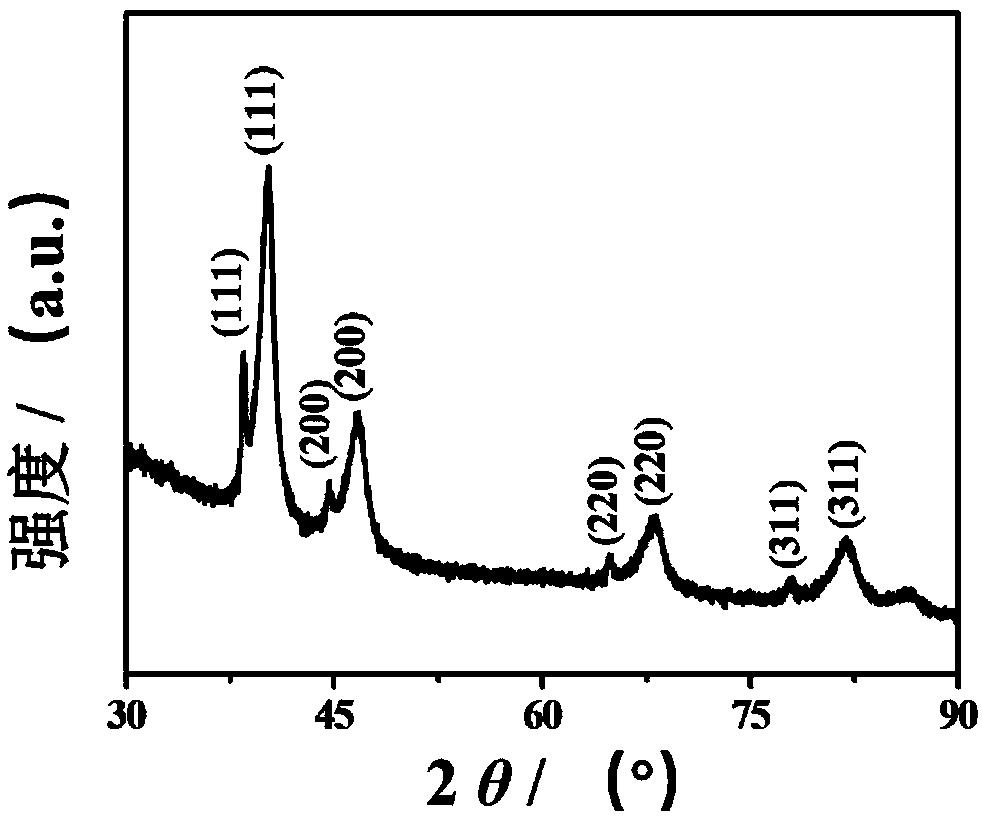

[0038] The SEM figure of the obtained platinum-palladium-gold nanometer mesop...

Embodiment 2

[0041] A preparation method of mesoporous platinum-palladium-gold electrocatalyst, said method comprising the steps of:

[0042] 1) Potassium chloroplatinite and sodium chloropalladate solutions with a concentration of 20mM, hydrochloric acid solution with a concentration of 6M and ascorbic acid solution with a concentration of 0.1M are prepared respectively;

[0043] 2) Mix 3mL of potassium chloroplatinite and 1mL of sodium chloropalladate solution, then add 50μL of hydrochloric acid solution, then add 40mg of F127, and ultrasonically dissolve it completely; finally add 4mL of ascorbic acid solution;

[0044] 3) After the solution is evenly mixed, place it in an ultrasonic cleaner and heat it to 40° C. After reacting for 4 hours, wash it with ultrapure water, collect the product by centrifugation, and dry it to obtain a mesoporous platinum-palladium-gold electrocatalyst.

[0045] It can be seen from the SEM image that when the metal precursors are only potassium chloroplatini...

Embodiment 3

[0047] A preparation method of mesoporous platinum-palladium-gold electrocatalyst, said method comprising the steps of:

[0048] 1) Potassium chloroplatinite, sodium chloropalladate and chloroauric acid solutions with a concentration of 5mM, hydrochloric acid solution with a concentration of 1M and ascorbic acid solution with a concentration of 0.02M are prepared respectively;

[0049] 2) Mix 2.4mL of potassium chloroplatinite, 0.8mL of sodium chloropalladate and 0.8mL of chloroauric acid solution, then add 10μL of hydrochloric acid solution, then add 10mg of F127, and ultrasonically dissolve it completely; finally Then add 1 mL of ascorbic acid solution;

[0050] 3) After the solution is evenly mixed, place it in an ultrasonic cleaning machine and heat it to 20° C. After reacting for 1 hour, wash it with ultrapure water, collect the product by centrifugation, and dry it to obtain a platinum-palladium-gold nanometer mesoporous methanol oxidation electrocatalyst.

[0051] Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com