Preparation method of nickel metal-organic framework material for adsorbing water-borne pollutants

A metal-organic framework and pollutant technology, applied in water pollutants, adsorbed water/sewage treatment, radioactive pollutants, etc., can solve the problem of low adsorption capacity, achieve high adsorption capacity, wide source of raw materials, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a nickel metal organic framework material for adsorbing pollutants in water, comprising the following steps:

[0036] Step S1: Mix nickel hydroxide and 20-30wt% hexafluorosilicic acid aqueous solution (the molar ratio of hexafluorosilicic acid and nickel hydroxide is 1:1.1), stir and react for 3-5 hours to obtain a green mixture.

[0037] Step S2: filter the green mixture with suction to obtain a green nickel hexafluorosilicate aqueous solution, and obtain green nickel hexafluorosilicate crystals after recrystallization.

[0038] Step S3: Mix the methanol solution of nickel hexafluorosilicate crystals with the methanol solution of 2-mercaptopyrazine (the molar ratio of nickel hexafluorosilicate to 2-mercaptopyrazine is 1:1 to 1:1.2, with 8- Heating at a rate of 12°C / min to 80-90°C for self-assembly reaction, and cooling down to room temperature after 6-8h of reaction, a yellow sample was obtained.

[0039] Step S4: Suction-filtering the yellow sa...

Embodiment 1

[0041] Preparation of nickel hexafluorosilicate: Take 2.1g of nickel hydroxide in a 100mL round bottom flask, then add 10mL of 25% aqueous solution of hexafluorosilicate, wherein the molar ratio of hexafluorosilicate to nickel hydroxide is 1:1.1, The reaction was stirred at room temperature for 4h. Suction filter with a Buchner funnel to obtain a green solution, dry and remove water to obtain green hexafluorosilicate crystals for future use.

[0042] The nickel hexafluorosilicate prepared by the above method is a self-made raw material under optimal conditions, and has high phase purity. The nickel hexafluorosilicate in the subsequent examples all adopts this synthesis method.

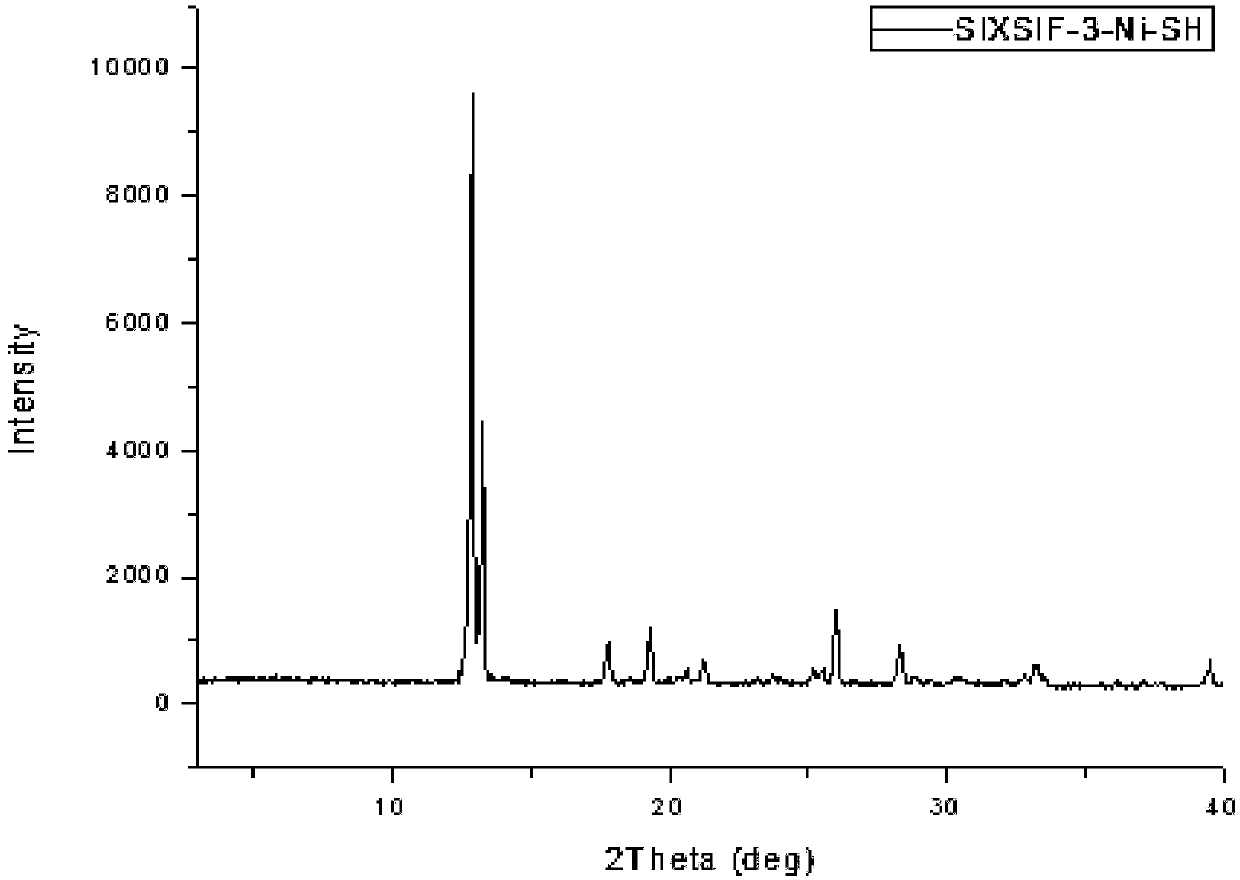

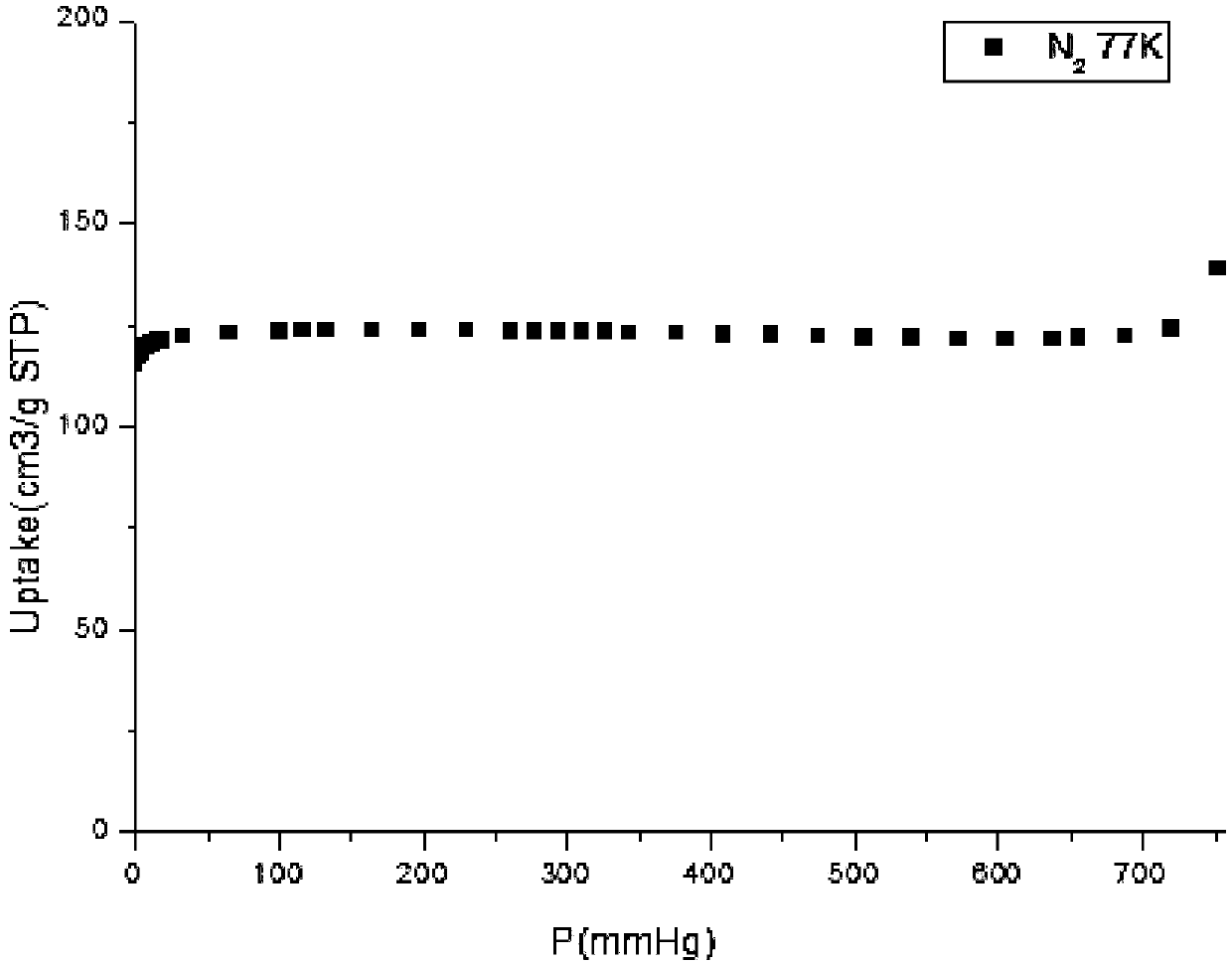

[0043] Preparation of nickel metal-organic framework (referred to as SIXSIF-3-Ni-SH): 0.200g of nickel hexafluorosilicate was dissolved in 10mL of methanol solution and 0.112g of 2-mercaptopyrazine, an organic ligand that introduced mercapto functional groups, respectively. Dissolve in 22.4mL of metha...

Embodiment 2

[0045] The difference from Example 1 is that the reaction temperature is 85°C, the reaction vessel is a 50mL polytetrafluoroethylene reactor, and the reaction time for preparing nickel metal-organic framework material (marked as SIXSIF-3-Ni-SH) is 6h .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com