A broadband wave-transparent multilayer ceramic matrix composite material and its preparation method

A composite material and multi-layer structure technology, which is applied in the field of composite materials, can solve problems such as the inability to use high-temperature environments, limited broadband wave-transmitting performance, and poor high-temperature reliability, and achieve excellent broadband wave-transmitting performance without affecting wave-transmitting performance. The effect of reliable connection action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

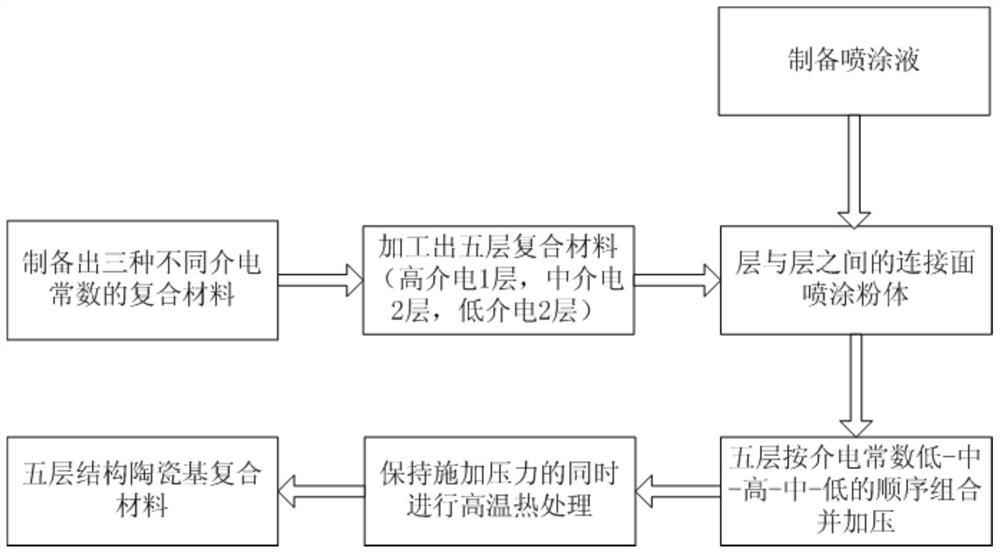

[0039] The embodiment of the present invention also provides a method for preparing a broadband wave-transmissive multilayer structure ceramic matrix composite material, comprising the following steps:

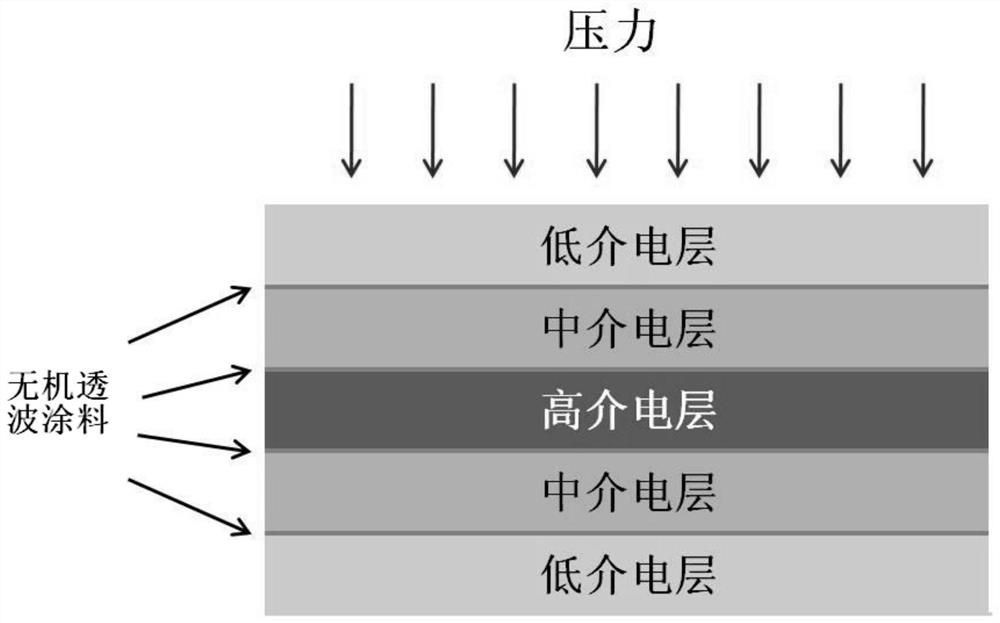

[0040] (1) Stack odd-numbered layers of inorganic wave-transparent fiber-reinforced ceramic matrix composites in order of increasing dielectric constant from the outer layer to the middle layer, and apply inorganic wave-transparent coatings between adjacent two layers before stacking;

[0041] (2) Apply pressure to make each layer in close contact, and perform heat treatment to obtain a multilayer structure ceramic matrix composite material.

[0042] The embodiment of the present invention is used to prepare the broadband wave-transmitting multilayer structure ceramic matrix composite material provided in the above embodiment. For the description of the product, refer to the above embodiment and will not repeat it here.

[0043] In an optional embodiment, in step (1), five lay...

Embodiment 1

[0052] An embodiment of the present invention provides a silicon nitride fiber reinforced ceramic matrix composite material with a 5-layer structure, and its preparation method includes:

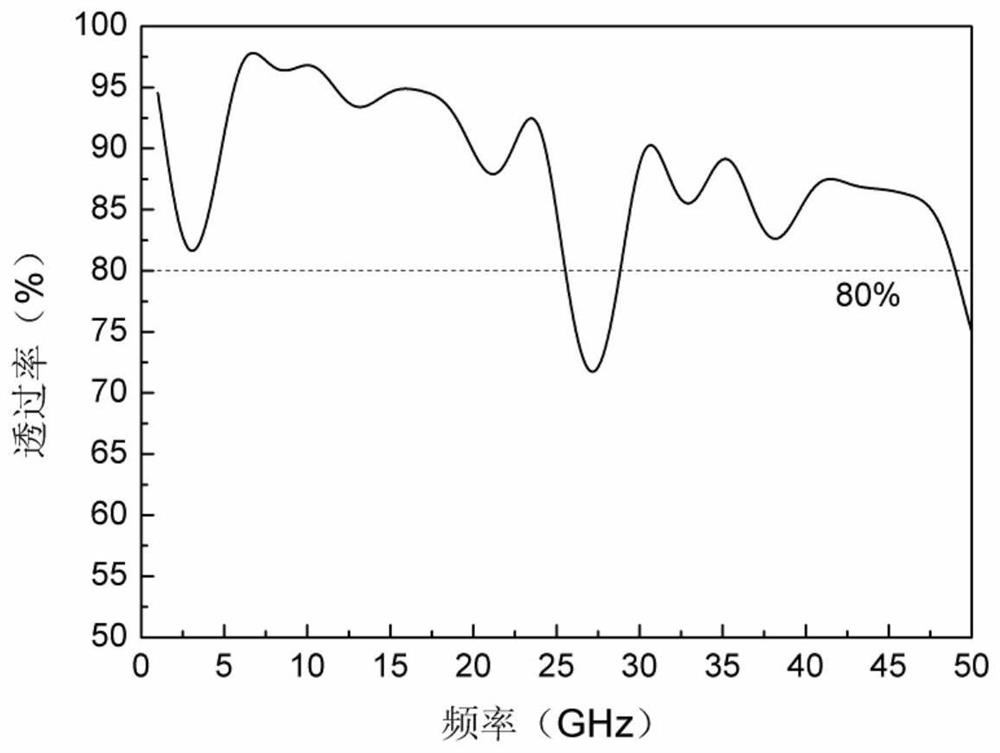

[0053] Such as figure 1 As shown, three silicon nitride fiber-reinforced ceramic matrix composites with different dielectric constants were prepared respectively, and were combined into a five-layer structure in the order of low-medium-high-medium-low dielectric constants, as shown in figure 2 As shown, the dielectric constant of the middlemost high dielectric layer is 4.0, the dielectric constant of the two layers adjacent to the middle layer (middle dielectric layer) on both sides is equal to 2.8, and the dielectric constant of the two outer low dielectric layers is The electrical constant is equal to 1.8; the thickness of each layer of the five-layer structure is the same, both are 3.0mm, and the length and width are both 120×120mm. Spray the spray liquid (inorganic wave-transparent coa...

Embodiment 2

[0055] An embodiment of the present invention provides a silicon nitride fiber reinforced ceramic matrix composite material with a 5-layer structure, and its preparation method includes:

[0056] Three mullite fiber-reinforced ceramic matrix composites with different dielectric constants were prepared respectively, and were combined into a five-layer structure in the order of low-medium-high-medium-low dielectric constant, and the middle high dielectric layer The dielectric constant is 2.8, the dielectric constants of the two layers adjacent to the middle layer (intermediate dielectric layer) on both sides are equal to 1.8, and the dielectric constants of the two outer low dielectric layers are equal to 1.2; the five-layer structure each The thickness of the layers is the same, both are 5.0mm, and the length and width are both 150×150mm. Coat the surface of the material with quartz-based glass phase powder by spraying spray liquid on the connection surface between layers in ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com