Ammonium removal process of ammonium-containing waste water

A waste water and ammonium removal technology, which is applied in the direction of ammonium chloride, ammonium halide, water pollutants, etc., to achieve the effects of reducing treatment costs, reducing material quality, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment discloses a process for removing ammonium from ammonium-containing wastewater. The ammonium-containing wastewater is vanadium-precipitated wastewater undergoing deep vanadium removal, and the vanadium-precipitated wastewater contains 200 g / L of sodium sulfate and 130 g / L of ammonium sulfate. , the vanadium precipitation wastewater enters the multi-effect evaporator, and evaporates to obtain sodium sulfate / ammonium sulfate crystals;

[0039] The content of sodium sulfate in sodium sulfate / ammonium sulfate crystals is 60%wt, and the content of ammonium sulfate is 40%wt;

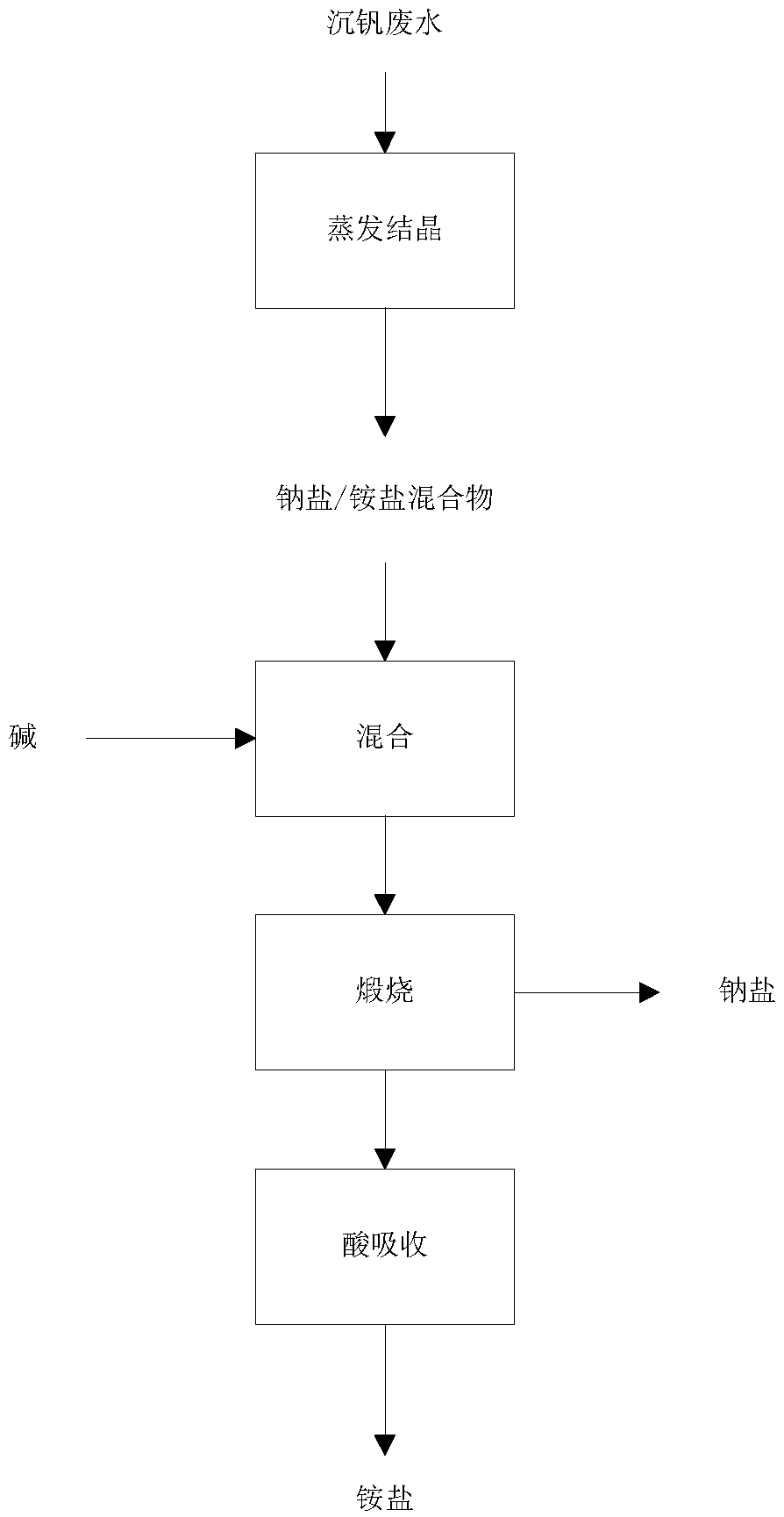

[0040] Specifically, the deammonization process of the ammonium-containing wastewater, such as figure 1 Visible, including the following steps:

[0041] Mix the above crystals with sodium hydroxide powder, the mixing ratio is 1t:243Kg; the gas released during the mixing process is absorbed by sulfuric acid spray to obtain ammonium sulfate solution;

[0042] Send the mixed materials into...

Embodiment 2

[0046] This embodiment discloses a process for removing ammonium from ammonium-containing wastewater. The ammonium-containing wastewater is vanadium-precipitated wastewater undergoing deep vanadium removal. The vanadium-precipitated wastewater contains 150 g / L of sodium chloride and 150 g of ammonium chloride. / L, the vanadium precipitation wastewater enters the MVR evaporator, and evaporates to obtain sodium chloride / ammonium chloride crystals;

[0047] The sodium chloride content in the sodium chloride / ammonium chloride crystal is 51%wt, and the ammonium chloride content is 49%wt;

[0048] Mix the above-mentioned crystals and sodium carbonate powder in a ratio of 1t: 390Kg and put them into a sagger. The gas released during the mixing process is sprayed and absorbed by hydrochloric acid to obtain an ammonium chloride solution; push the sagger into a pusher kiln at 400°C , calcined for 1h;

[0049] Spray and absorb the tail gas produced by calcination with 3mol / L hydrochlori...

Embodiment 3

[0052] This embodiment discloses a process for removing ammonium from ammonium-containing wastewater. The ammonium-containing wastewater is vanadium-precipitated wastewater undergoing deep vanadium removal. The vanadium-precipitated wastewater contains 100 g / L of sodium sulfate and 250 g / L of ammonium sulfate. , enter the spray dryer, evaporate to obtain the crystal of sodium sulfate / ammonium sulfate;

[0053] The content of sodium sulfate in sodium sulfate / ammonium sulfate crystal is 29%wt, and the content of ammonium sulfate is 71%wt;

[0054] Mix the above-mentioned crystals and sodium carbonate powder in a ratio of 1t: 570Kg and put them into a stainless steel crucible. The gas released during the mixing process is sprayed and absorbed by sulfuric acid to obtain an ammonium sulfate solution; push the stainless steel crucible into a tunnel kiln at 500°C for calcination 0.5h;

[0055] Spray and absorb the tail gas produced by calcination with 4mol / L sulfuric acid to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com