A biodiesel residue treatment device

A biodiesel and processing device technology, which is applied in the petroleum industry, coking carbonaceous materials, coking ovens, etc., can solve the problems of biomass asphalt viscosity increase until hardening and solidification, production interruption, and difficulty in separation, so as to improve efficiency, Improve the overall yield and increase the effect of heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

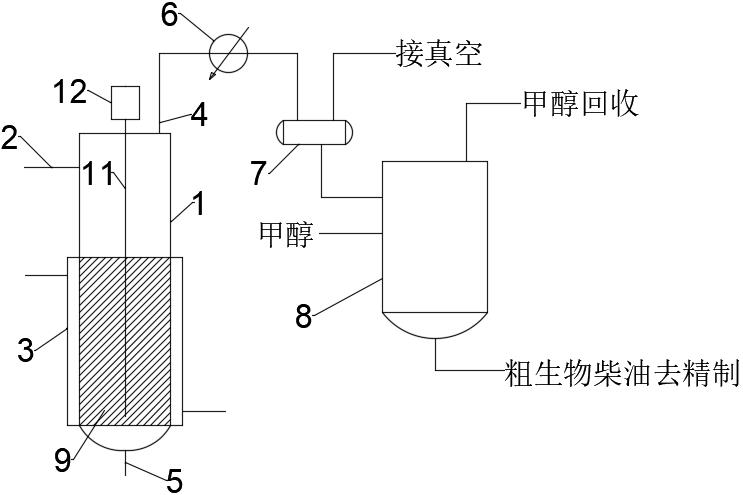

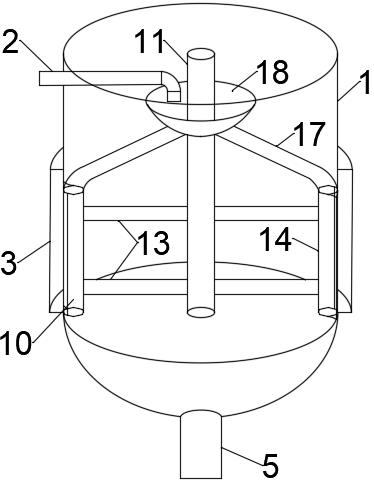

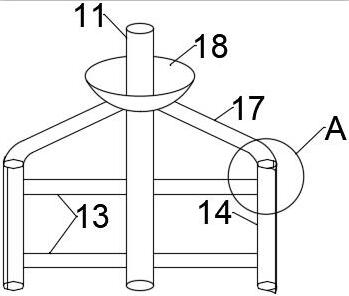

[0029] A biodiesel residue treatment device, comprising a cracking tank 1, the upper part of the side wall of the cracking tank 1 is provided with a biomass asphalt feed pipe 2, the middle and lower part of the side wall is provided with a heating jacket 3, and the top is provided with a cracking gas outlet 4 , the bottom is provided with a carbonized particle outlet 5; the cracked gas outlet 4 is connected to the condenser 6 through a pipeline, and the cooled liquid is passed into the condensate buffer tank 7, and at least three openings are provided on the condensate buffer tank 7, And connect described condenser 6, vacuum pump and esterification kettle 8 respectively.

[0030] In the heating jacket 3, conventional middle and high temperature heating means in the field such as molten salt, heat conduction oil, electromagnetic heating, etc. can be used, so that the inner wall of the middle and lower part of the cracking tank 1 corresponding to the heating jacket 3 becomes capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com