Making method of pour fish soup powder

A production method and soup powder technology, which is applied in the direction of dairy products, food ingredients as taste improvers, food ingredients as odor improvers, etc., can solve the problems of not being widely used, increasing storage costs, and limiting the amount of product processing, etc., to achieve Reduce the loss of flavor, increase the layering, and enrich the flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

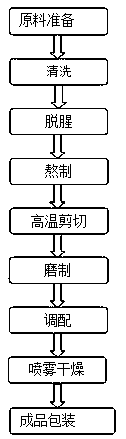

[0021] The process steps of the preparation method of pure fish broth powder of the present invention are described in detail as follows with reference to the accompanying drawings.

[0022] Reference figure 1 As shown in the schematic diagram of the processing steps of the manufacturing method of pure fish broth powder of the present invention, the manufacturing method includes the following steps:

[0023] S1, raw material preparation: choose fresh, odor-free rainbow trout racks with or without fish heads;

[0024] S2, cleaning: picking the prepared raw materials, removing the outer packaging, and cleaning the raw materials in the cleaning tank to remove blood;

[0025] S3, deodorization: heat in a high-temperature cooking tank to bring the water temperature to 100℃, and then put the washed rainbow trout bones into the cooking tank through the extraction cage. After maintaining for 5 minutes, drain the water and re-add the rainbow trout. 40% water of bone mass, add 1%-1.5% cooking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com