A kind of shale gas development using reduced oxygen air/liquid CO 2 Double Interface Layer Foam Fracturing Fluid

A foam fracturing fluid and double-interface technology, applied in chemical/physical processes, chemical instruments and methods, drilling compositions, etc., can solve problems such as damage to formation matrix, clay expansion, and proppant filling layer damage, and achieve The effect of reducing the demand for water resources, good temperature resistance and stability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

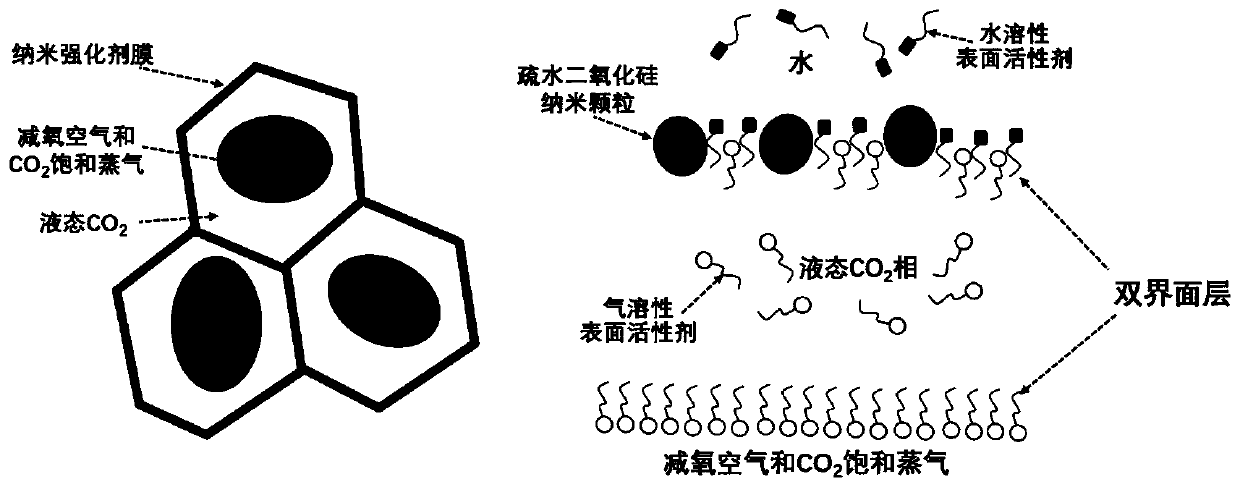

[0064] Example 1, shale gas development uses oxygen-reduced air / liquid CO 2 Double Interface Layer Foam Fracturing Fluid

[0065] from liquid CO 2 phase, gas phase, and nano-enhancers, of which:

[0066] Liquid CO 2 The phase is an aerosol surfactant complex dissolved in liquid CO 2 made, aerosol-soluble surfactants in liquid CO 2 The initial volume ratio of the mixture is 0.5%, and the air-soluble surfactant compound is composed of 2-trifluoromethane-3-methoxydecafluoropentane and fluorobutane ethyl ether in a mass ratio of 1:3.3 compound.

[0067] The gas phase consists of oxygen-reduced air and liquid CO 2 The saturated vapor composition, the oxygen content in the oxygen-reduced air is 4%, and the gas partial pressure of the oxygen-reduced air is liquid CO 2 1.3 times the partial pressure of saturated vapor.

[0068] The nano-strengthening agent comprises hydrophobic silicon dioxide nanoparticles with a mass fraction of 1.0%, ethanol with a mass fraction of 0.2%, a ...

Embodiment 2

[0077] Example 2, shale gas development using oxygen-reduced air / liquid CO 2 Double Interface Layer Foam Fracturing Fluid

[0078] from liquid CO 2 phase, gas phase, and nano-enhancers, of which:

[0079] Liquid CO 2 The phase is an aerosol surfactant complex dissolved in liquid CO 2 made, aerosol-soluble surfactants in liquid CO 2 The initial volume ratio of the mixture is 0.6%, and the air-soluble surfactant compound is composed of 3-ethoxytridecafluorohexane and fluorobutane ethyl ether in a mass ratio of 1:4.5.

[0080] The gas phase consists of oxygen-reduced air and liquid CO 2 Composed of saturated vapor, the oxygen content in the oxygen-reduced air is 4%, and the gas partial pressure of the oxygen-reduced air is liquid CO 2 1.5 times the partial pressure of saturated vapor.

[0081] The nano-strengthener comprises 1.5% by mass fraction of hydrophobic silicon dioxide nanoparticles, 0.25% by mass fraction of ethanol, 0.5% by mass fraction of a water-soluble surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com