Preparation method of pre-embedded lithium cathode and prepared pre-embedded lithium cathode, energy storage device, energy storage system and electric equipment

A technology of pre-embedded lithium and negative electrode, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of increasing the overall cost of the battery, and achieve the effects of low device cost, good cycle performance, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

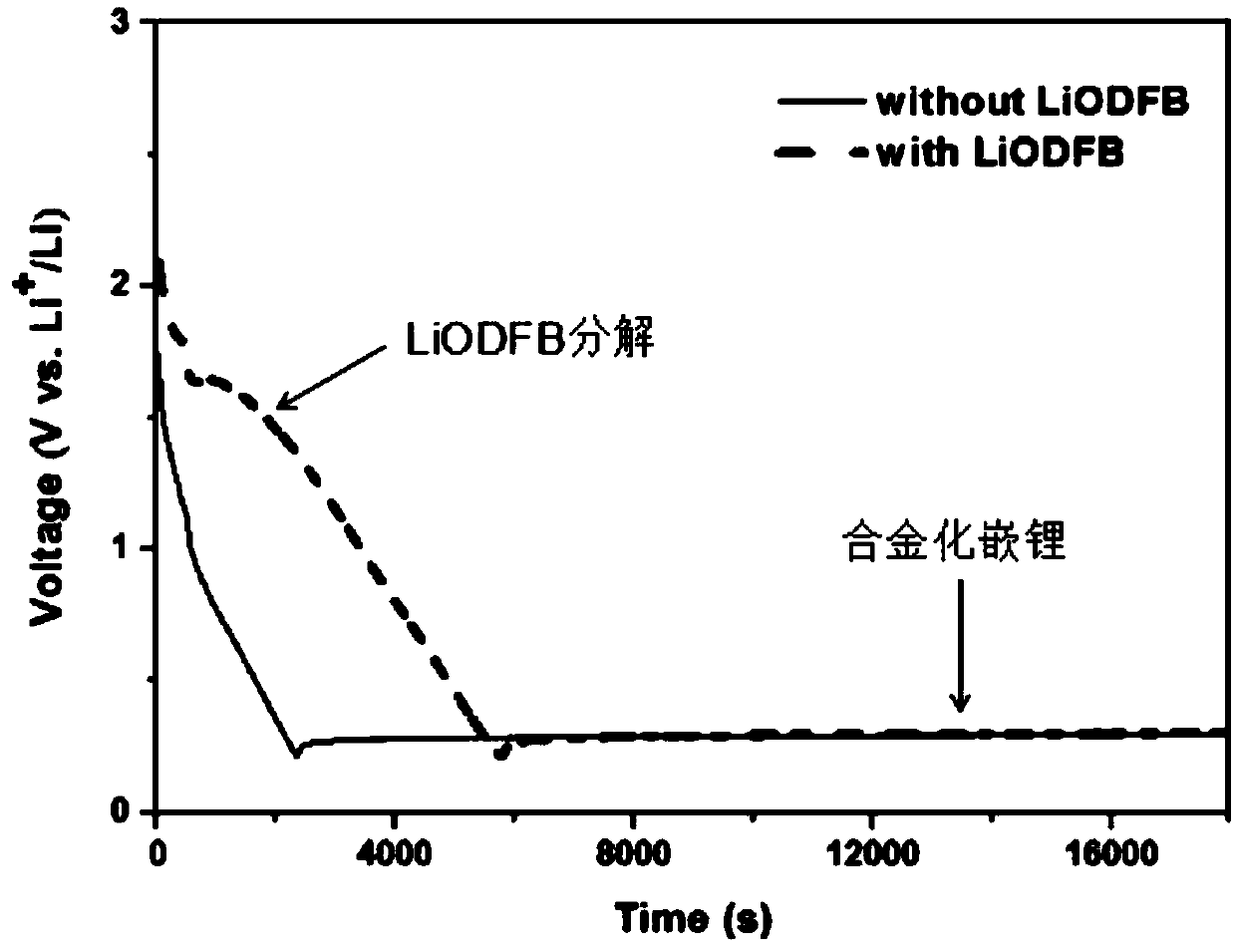

[0074] In the preparation method of the above-mentioned pre-intercalated lithium negative electrode, the metal material is used as the working electrode, the material capable of providing lithium source is used as the counter electrode, and the lithium salt solution containing additives is used as the electrolyte to charge or discharge the assembled half-cell. The working mechanism of the above-mentioned pre-intercalated lithium is: in the process of charging or discharging, the additive in the electrolyte first decomposes, thereby forming an SEI passivation film on the surface of the metal material, and in the process of further charging or discharging, lithium ions pass through the passivation film An alloying reaction occurs with the metal material to form an alloy of the metal material and lithium, thereby completing the process of pre-intercalating lithium. The counter electrode is mainly to provide a lithium source for pre-intercalation of lithium; the working electrode u...

Embodiment 1

[0128] A method for preparing a pre-intercalated lithium negative electrode, comprising the following steps:

[0129] a) Take an aluminum foil with a thickness of 50 μm, cut it into a disc with a diameter of 12 mm, wash it with acetone and ethanol, dry it and place it in a glove box as a working electrode for standby;

[0130] b) Weigh a certain amount of lithium hexafluorophosphate in the glove box, and add it to a mixture of ethylene carbonate, dimethyl carbonate and diethyl carbonate (the volume ratio of the three is 1:1:1) to prepare 1M lithium hexafluorophosphate electrolyte;

[0131] c) Weigh a certain amount of lithium difluorooxalate borate, stir until completely dissolved, and prepare an electrolyte solution with a final additive content of 10wt.%.

[0132] d) Cut the glass fiber paper into discs with a diameter of 16mm, dry it in vacuum at 80°C for 12 hours, and place it in a glove box as a diaphragm for later use;

[0133] e) In a glove box with an argon atmospher...

Embodiment 2-13

[0135] A method for preparing a pre-intercalated lithium negative electrode. The difference from Example 1 is that the mass fraction of lithium difluorooxalate borate in the electrolyte in Examples 2-13 is different, and other steps and parameters are the same as in Example 1.

[0136] The lithium ion capacitor comprising the pre-embedded lithium negative electrode prepared in Examples 1-13, the preparation method comprises the following steps:

[0137] a) Weigh a certain amount of lithium hexafluorophosphate in the glove box, and add it to a mixture of ethylene carbonate, dimethyl carbonate and diethyl carbonate (the volume ratio of the three is 1:1:1) to prepare 1M lithium hexafluorophosphate electrolyte;

[0138] b) Add 0.8g of activated carbon (AC), 0.1g of conductive carbon black, and 0.1g of polyvinylidene fluoride into 2mL of N-methylpyrrolidone, grind thoroughly to obtain a uniform slurry; then evenly coat the slurry on the surface of the aluminum foil, Vacuum dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com