Composition containing proteins and plant fibers

A plant fiber and composition technology, which is applied in the field of composition containing protein and plant dietary fiber, can solve the problems of affecting the taste, unresolved combination solubility of animal protein and plant protein, heavy bean flavor, etc., to achieve smooth taste, Good solubility, no grainy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

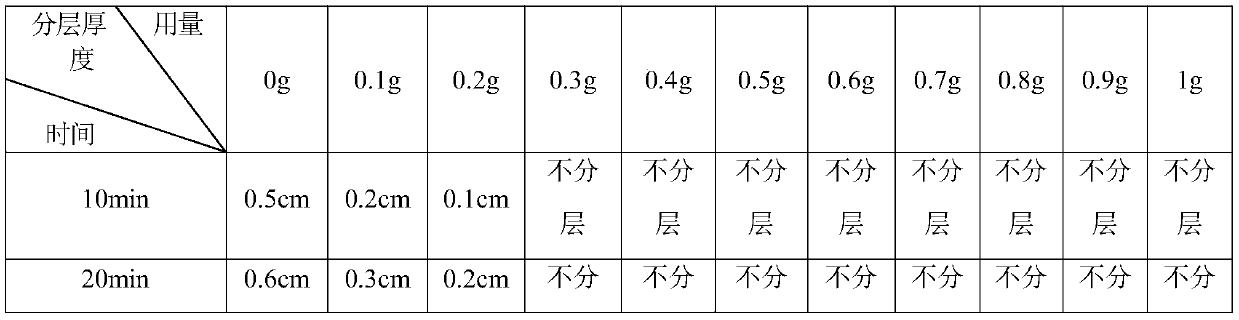

[0022] The selection of experimental example 1 xanthan gum consumption

[0023] 1. The purpose of the experiment: In the case of the same content of other ingredients, add different amounts of xanthan gum to investigate the dissolution of the sample

[0024] 2. Experimental steps:

[0025] (1) Each raw material is passed through a 60-mesh sieve, and set aside.

[0026] (2) Premixing: Add 10g of pea dietary fiber, 2g of resistant dextrin, 2g of caprylic glyceride, 1g of calcium hydrogen phosphate, 0.5g of galactooligosaccharide, and different amounts of xanthan gum in Table 1 to In the mixer, mix uniformly in equal increments to obtain a premixed material.

[0027] (3) Total mixing: put 40.1-41.1g of maltodextrin, 20g of pea protein, 20g of whey protein, 3g of membrane-separated casein, 0.4g of isolated whey protein, and the premixed materials of step (2) in a mixer Mix well and serve.

[0028] (4) First add 250ml of warm water to the cup, then add 60g of the prepared compo...

experiment example 2

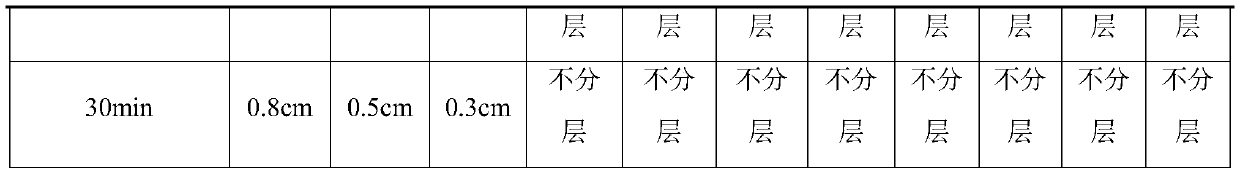

[0034] The selection of experimental example 2 caprylic capric acid glyceride dosage

[0035] The purpose of the experiment: In the case of the same content of other ingredients, add different amounts of caprylic acid glyceride to investigate the dissolution of the sample

[0036] 2. Experimental steps:

[0037] (1) Each raw material is passed through a 60-mesh sieve, and set aside.

[0038] (2) Premixing: 10g of pea dietary fiber, 2g of resistant dextrin, 0.5g of xanthan gum, 1g of calcium hydrogen phosphate, 0.5g of galactooligosaccharide, and different amounts of glyceryl capricate in Table 2, added Put it in the mixer and mix evenly in equal increments to obtain the premixed material.

[0039] (3) Total mixing: put 41.6-42.6g of maltodextrin, 20g of pea protein, 20g of whey protein, 3g of membrane-separated casein, 0.4g of isolated whey protein, and the premixed material of step (2) in a mixer Mix well and serve.

[0040] (4) First add 250ml of warm water to the cup, t...

Embodiment 1

[0047] (1) Each raw material is passed through a 60-mesh sieve, and set aside.

[0048] (2) Premixing: 10g of pea dietary fiber, 3g of resistant dextrin, 0.5g of xanthan gum, 1g of caprylic glyceride, 2g of calcium hydrogen phosphate, 6g of calcium caseinate, 0.4g of xylooligosaccharide, low Add 0.6 g of polygalactose, 0.8 g of silicon dioxide, 0.005 g of steviol glycoside, and 0.1 g of strawberry essence into a mixer and mix them uniformly in equal increments to obtain a premixed material.

[0049] (3) Total mixing: fully mix 43.295g of maltodextrin, 20g of pea protein, 15g of whey protein, 3g of membrane-separated casein, and 0.3g of isolated whey protein with the premixed material in step (2) in a mixer Evenly, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com