Viscosity reducer, preparation method thereof, and paper coating

A technology of viscosity reducer and slurry, which is applied in paper coating, paper, textile and papermaking, etc. It can solve the problems of coating streaks, viscosity increase, drying on rollers, etc., and achieve high shear viscosity reduction and good viscosity reduction Effect, effect of dispersion and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

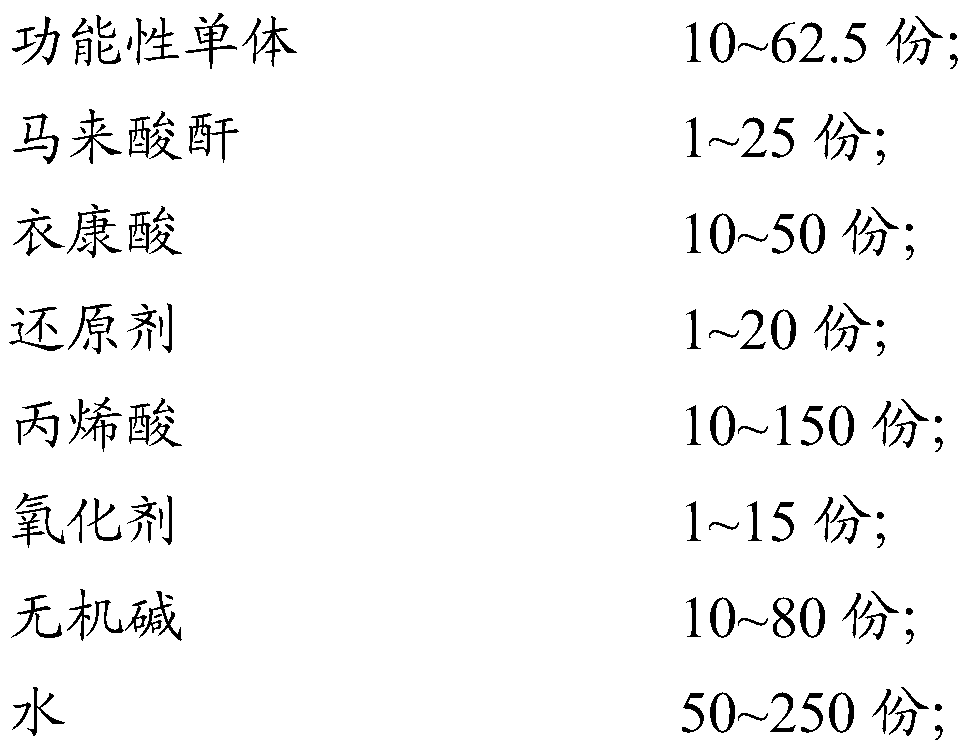

[0037] The present invention provides the preparation method of the viscosity reducer described in the above technical scheme, comprising the following steps:

[0038] (1) Mix functional monomers, maleic anhydride, part of itaconic acid, part of reducing agent and water, and mix at 78-85°C to obtain the first slurry;

[0039] (2) Mix the first slurry with part of acrylic acid and part of oxidant, keep it warm at 75-85°C for 2.5-3.5 hours, and carry out polymerization reaction to obtain the second slurry;

[0040] (3) mixing the second slurry with the remaining itaconic acid, the remaining reducing agent, the remaining acrylic acid and the remaining oxidizing agent, keeping the temperature at 75-85° C. for 2.5-3.5 hours, and performing a polymerization reaction to obtain the third slurry;

[0041] (4) Mixing the third slurry with an inorganic base to obtain a viscosity reducer.

[0042] The present invention mixes functional monomers, maleic anhydride, part of itaconic acid, p...

Embodiment 1

[0055] In terms of parts by weight, put 62.5 parts of allyl polyoxyethylene ether in a four-necked flask, raise the temperature to 80°C, make it melt, then add 200 parts of water, heat to 80°C, and then add 25 parts of maleic anhydride , 22.5 parts of itaconic acid, 6.4 parts of sodium hypophosphite and 42 parts of water are heated up to 80°C to obtain the first slurry;

[0056] 28.13 parts of acrylic acid and 7 parts of ammonium persulfate were successively added dropwise to the first slurry, the total dropping time was 1 hour, and the temperature was kept at 80° C. for 2.5 hours to obtain the second slurry;

[0057] Add 27.5 parts of itaconic acid and 9.6 parts of sodium hypophosphite to the second slurry, then add 34.37 parts of acrylic acid and 7 parts of ammonium persulfate dropwise, the total dropping time is 1 hour, and keep warm at 80°C for 3 hours , to obtain the third slurry;

[0058] The temperature of the obtained third slurry was lowered to 45° C., 50 parts of so...

Embodiment 2

[0061] In parts by weight, put 50 parts of methallyl alcohol polyoxyethylene ether into a four-necked flask, heat up to 80°C, make it melt, then add 180 parts of water, heat to 80°C, and add 12.5 parts of horse Toric anhydride, 22.5 parts of itaconic acid, 7 parts of sodium hypophosphite and 44 parts of water are heated up to 80°C to obtain the first slurry;

[0062] Add 60 parts of acrylic acid and 7.7 parts of ammonium persulfate successively dropwise to the first slurry, the total dropping time is 1 hour, keep warm at 80°C for 3 hours, to obtain the second slurry;

[0063] Add 15 parts of itaconic acid and 7 parts of sodium hypophosphite to the second slurry, then dropwise add 40 parts of acrylic acid and 6.3 parts of ammonium persulfate in sequence, the total time of dropping is 1.5h, and keep warm at 80°C 3h, obtain the third slurry;

[0064] The temperature of the obtained third slurry was lowered to 45° C., 70 parts of sodium hydroxide was added, and stirred for 0.5 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com