Fluidized bed device and method for converting methanol into aromatics with different functions

A methanol conversion and fluidized bed technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, condensation hydrocarbon production with dehydrocarbons, etc., can solve the inability to achieve complete methanol conversion and the decline in methanol conversion rate , waste water treatment and other problems, to achieve the effect of less recycled materials, reduced recycled materials, and increased aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

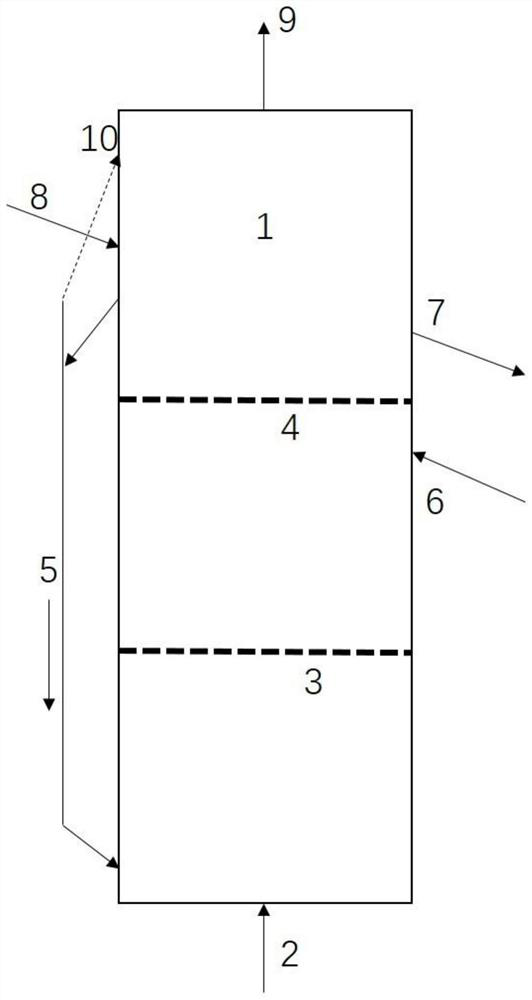

[0037] Fill catalyst (zinc oxide, lanthanum oxide, ZSM-5, kaolin, aluminum oxide, its mass fraction is respectively 3%, 7%, 70%, 10%, 10% in the three-stage fluidized bed 1 by catalyst filling port 8 %). After preheating to 250°C, feed methanol-containing material (50% methanol, 50% C 2 -C 10 Mixed ester), through the gas inlet 2 and the porous distribution plate one 3, between the porous distribution plate one 3 and the porous distribution plate two 4, the catalyst accumulation area between the porous distribution plate two 4 and the gas outlet 9, and control the temperature The reaction was carried out at 380°C, 580°C, and 500°C respectively, and the catalyst space velocity was 0.1kg methanol / kg catalyst / hour. After the reaction, water, mixtures of aromatic hydrocarbons, light hydrocarbons and hydrogen are generated, and the three-stage fluidized bed 1 is discharged from the gas outlet 9 .

[0038] The deactivated catalyst is taken out through the deactivated catalyst out...

Embodiment 2

[0041] Fill catalyst (gallium, copper, cerium oxide, ZSM-5, silicon oxide, aluminum oxide, its mass fraction is respectively 3%, 7%, 20%, 30% in the three-stage fluidized bed 1 by catalyst filling port 8 , 10%, 30%). After preheating to 300°C, feed methanol-containing material (80% methanol, 14% acetone, 1% ethyl acetate, 5% pentane, 7% cyclohexene, 3% glycerol) from the gas inlet 2, followed by After passing through the catalyst accumulation area between the gas inlet 2 and the porous distribution plate 1 3, between the porous distribution plate 1 3 and the porous distribution plate 2 4, and between the porous distribution plate 2 4 and the gas outlet 9, the control temperature is 490°C, The reaction was carried out at 550°C and 450°C, and the catalyst space velocity was 20kg methanol / kg catalyst / hour. After the reaction, water, mixtures of aromatic hydrocarbons, light hydrocarbons and hydrogen are generated, and the three-stage fluidized bed 1 is discharged from the gas out...

Embodiment 3

[0045] Catalysts (ZSM-12, silicon oxide, the mass fractions of which are 30% and 70% respectively) are loaded into the three-stage fluidized bed 1 from the catalyst replenishment port 8 . After preheating to 300°C, methanol is introduced from gas inlet 2, and passes through gas inlet 2 and porous distribution plate 1 in sequence, between porous distribution plate 1 3 and porous distribution plate 2 4, and between porous distribution plate 2 4 and gas In the catalyst accumulation area between the outlets 9, the temperature is controlled at 450°C, 550°C, and 450°C for the reaction, and the catalyst space velocity is 0.3kg methanol / kg catalyst / hour. After the reaction, water, mixtures of aromatic hydrocarbons, light hydrocarbons and hydrogen are generated, and the three-stage fluidized bed 1 is discharged from the gas outlet 9 .

[0046] The deactivated catalyst is drawn out through the deactivated catalyst outlet 7, and regenerated at 600°C by passing air on other devices. Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com